As October 2012 faded into November, Superstorm Sandy left 8.2 million customers without electricity along the East Coast, 1.4 million of which were Consolidate Edison of New York (Con Edison) customers. Restoration costs exceeded US$520 million.

It took several weeks for all of the customers in the Northeast to have their power restored. For utilities, however, the impact of the storm still echoes loudly more than a year later. For Con Edison, Sandy provided a unique opportunity to launch new technology to improve its storm management.

Following the immediate storm cleanup and power-restoration efforts, Con Edison also faced reconstruction of damaged assets. Rather than simply replacing what had been damaged, the utility conducted internal reviews to identify new ways to reinforce the system as well as to avoid catastrophic damage and long-term future outages.

Looking for New Ways

Fresh initiatives included not only reinforcing the physical plant, raising substation equipment and undergrounding vulnerable overhead lines, but also reviewing the storm-management processes themselves along with the systems designed to handle major interruptions.

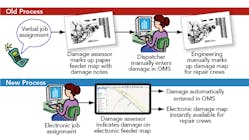

The Edison Project team at Con Edison has been focusing on process improvements of the distribution system since 2007. Hurricane Sandy provided the opportunity to combine new technology and lean management practices to redesign the damage-assessment process. Con Edison quickly introduced an innovative solution that entailed upgrading from a manual paper-based data entry process to a wireless tablet solution, which was integrated with the internal outage management system (OMS) in just three months.

Con Edison’s goal is to provide customers with early and accurate estimated restoration times so customers can plan their lives accordingly. Two pieces of critical information are needed in the aftermath of a storm to accomplish this. First is an assessment of the storm damage to understand the amount of required repairs. Second is the size of the workforce available to make the repairs, particularly when the repairs are beyond Con Edison’s internal capability. Con Edison relies on assistance from other utilities’ workforces in restoration; this project will help to accelerate the time it takes to get the damage-assessment information to Con Edison restoration planners.

Process Improvement Meets Technology

Assessing damage after Superstorm Sandy took Con Edison workers more than a week to complete. The work was performed primarily using paper and pencil, with information turned in at the end of a damage assessor’s shift. Much of the assessment also was performed by contracted damage assessors and mutual-aid crews from other utilities outside of the Northeast region. Many of these crews were unfamiliar with the Con Edison system and geography.

In the course of a shift prior to the end of the storm, engineering printed hard copies of the feeder maps and distributed them to the damage-assessment team. At the end of the storm, when it was safe to identify the damages, damage assessors were deployed to patrol the feeders. Assessors either called their coordinators, if cellular connectivity was available, or entered the damage information manually into the OMS at the end of their shift. Con Edison engineering then reviewed the location of the damages, prioritized repairs, prepared paper-based work packages and distributed them to the overhead construction crews.

Without an integrated, transparent visualization tool, duplication of assessments, crew assignments and restoration time estimates were common and obviously inefficient. The Edison Project team worked with engineering, operations, damage-assessment teams and information technology specialists to refine the process and find a technology partner to help implement the planned improvements. They searched the marketplace for software, met with vendors and compared the offerings with some internal interim solutions, as well.

The Mapping Challenge

The biggest challenge for Con Edison was the existing mapping systems lacked logical geospatial features, which are currently being worked on in the phase-zero development stage. The effort to conflate the mapping systems quickly, integrate them with existing legacy systems and develop a cost-effective, user-friendly technological tool is critical to bridging existing gaps. A two-phase strategy was formulated to address these needs.

The first phase was an interim solution to implement a new intranet-based tool that damage assessors can use while in the field. Rather than taking handwritten notes on a feeder map and bringing the paper back to a central location where it is entered into the OMS, assessors would complete a form with all of the relevant information for each location and submit it electronically as soon as a wireless signal was available on their device. Relaying damage information wirelessly would significantly cut down on the time it takes to complete the damage-assessment process in each locality, resulting in faster restoration at the circuit level.

The second phase was to pilot and implement a map-based visualization application that would allow damage assessors to record and transmit more detailed visual information about system damage. This application would be preloaded onto Internet-enabled tablets before dispatch. As assessors patrol their assigned circuits, they would record information on a digital map of the circuit — populating the same data fields as in the first-phase intranet form — and take pictures and video, as appropriate, to illustrate the situation in detail. Assessors also could mark up the map and highlight portions of the system that are affected. Data and photos would then be transmitted wirelessly in near real time back to a central repository.

Technology Partner

After presentations and discussions, followed by a successful field pilot in four New York City boroughs and in Westchester County, Con Edison chose the Electric System Damage Assessment (ESDA) application from SAMsix, whose European field technology partner, Sigma Seven, provides specialty engineering applications for the utility industry.

ESDA was able to complement the existing Con Edison OMS by integrating with the assignment work module in the OMS. This innovation enhances the ability to dispatch damage assessors and receive completed reports from the field in the intranet-based application.

Distribution network drawings from Con Edison’s different legacy geographic information systems were combined and conflated to provide a seamless feeder and equipment map aligned to real-world coordinates. This central data set was then synchronized with tablet computers running Sigma Seven’s GeoField software.

Operation

A central intranet-based management console in ESDA pinpoints the physical location of all active damage assessors, through an included automatic vehicle location module, and displays damage reports as they return from the field. The actual progress by either individual assessors or for the total system also can be tracked from the management console. When areas of poor network connectivity are encountered, as experienced during Sandy, the tablets can store the damage reports and automatically transmit the data as soon as a sufficiently strong network connection is established. This process occurs transparently to the damage assessors, who can work continuously using the full set of distribution maps and records onboard their secured mobile computers.

ESDA provides real-time summaries of damage, calculated by feeder/circuit, assignment or incident, as well as detailed reports on all damage recorded. Reports are exportable to Microsoft Excel and include graphics packages showing textual details alongside localized maps with accompanying photographs and sketches. Pole-by-pole assessment enables the calculation of labor and material units that can accompany repair time estimates.

Back Office

The back-office functions as well as the GeoField tablet software were designed to be intuitive, with a lot of input from Con Edison subject-matter experts, and the effort paid off in a solution that is very user-friendly. The Edison project team also created a simple user guide, refresher video and quick-reference guide for field personnel. The entire system, including integration with corporate systems and mapping data alignment, was delivered after three months of intense work by the Edison Project team.

ESDA also is integrated with the Site Safety intranet application, which alerts dispatching field personnel to guard downed wires and ensure public and employee safety. In addition, ESDA provides alerts for oil spills. This quick notification expedites a specific site’s repair process and can minimize the extent of the environmental impact.

Work Flow

Both specific site-by-site and feeder patrol assignments are possible with any field unit because all electric distribution data is held locally and job assignments are transmitted to field units automatically. Once damage assessors sign on, they receive their queue of work as provided through the management console. Damage assessors can attach multiple photographs, sketches, videos and supplementary field notes to their reports, and these are automatically tagged against assets in the corporate asset database.

The detailed asset information is directly retrieved from the mapping databases. For example, the correct size of a transformer or wire is automatically populated. With multi-point assignments, similar to feeder patrols, driving directions are automatically calculated to minimize travel time.

These instructions are sent to the field units along with other job details. This ensures that, if the assessors later encounter poor network connectivity, they could still complete the queue of work or the full feeder patrol.

Successful Improvements

In the next phase, with minor enhancement to ESDA, Con Edison engineers will use the ESDA for daily design and planning work to provide more accurate geospatial information, which will overlap with Google Earth or Bing maps.

With this tool’s success, improvements to the Con Edison storm plan will leap forward in an exponential fashion. It will not only improve damage assessment and restoration time estimates, but also fine-tune repair priorities and crew preparedness before arriving at the damage site. This eliminates manually matching paper reports to outages in the storm management systems and will free valuable engineering and operations personnel to perform modeling and prioritization tasks.

Con Edison views rapid damage assessment as the key to process changes that will improve overall response to major storm events.

Maggie Chow ([email protected]) is the section manager of the Edison Project at Consolidated Edison of New York. Over the last 20 years, she has held positions in the technical field services, substation maintenance, auditing, specification design and reliability improvement in distribution engineering, and led technological innovations to improve cost savings, operational excellence and process improvement solutions for Con Edison. She also has received the Innovator award from the Electric Power Research Institute.

Companies mentioned:

Con Edison | www.coned.com

SAMsix | www.samsix.com

Sigma Seven | www.sigmaseven.co.uk