In the March 2011 issue of Transmission & Distribution World, American Electric Power’s Emeka Okafor described how the utility has deployed battery energy storage across its distribution system. The potential benefits of implementing battery energy storage systems (BESS) at the substation were described as improving reliability both through supporting aging electrical infrastructure and providing backup power for customers. The BESS delivers these benefits through peak shaving and islanding.

Peak shaving is a function that allows the battery to discharge at times of high demand, thus reducing the peak load through the system and consequent stress on substation components. In addition to potentially extending the life of an asset, this function can defer the need for capital upgrades required to meet increasing demand. Islanding allows the battery to supply power to a portion of the distribution network when disconnected from the main grid because of a planned or unplanned outage. In this state, the battery is effectively acting as a backup power source.

In January 2010, BC Hydro initiated a project in partnership with Natural Resources Canada to install BESS on its distribution system in Golden, British Columbia, Canada, in the hopes of achieving both of these benefits.

Business Case

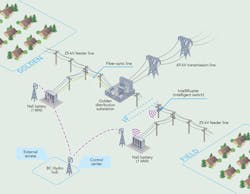

The two mountain communities of Golden and Field, in the East Kootenay region of British Columbia, have had significant reliability issues in the past.

Both towns receive power from the Golden substation, which uses four radial distribution feeders to supply the town of Golden and surrounding areas. In early 2010, the load forecast for the area predicted substation capacity would be exceeded by the winter peak of 2013-2014. The town of Field, located approximately 50 km (31 miles) to the east of Golden, is supplied by a single 25-kV feeder from Golden. This distribution line experiences frequent and prolonged outages because of the heavily forested environment and cold, snowy conditions of Yoho National Park, in which the town of Field is located. The feeder does not always follow the road, and the rugged terrain makes it especially difficult for crews to locate faults and restore power.

To provide both peak-shaving functionality at Golden and backup power to Field, BC Hydro’s team reviewed several alternatives including battery storage and diesel generation. The financial cost of deploying battery storage was weighed against the cost of diesel generation at both sites. Although the cleaner battery option was preferred, diesel generation was significantly cheaper. It was only with a matching funds award from the Canadian government’s Clean Energy Fund that a business case could be made for battery storage.

In the business case, the utility is expected to derive benefits from the batteries over a 15-year life cycle and defer the cost of transformer upgrades at the substation for two years. BC Hydro and the Canadian government had three main

objectives:

- Prove the business case

- Gain knowledge in the deployment of battery energy storage for peak shaving and islanding (for backup power)

- Understand the additional challenges of the Canadian climate and environment.

Early on, the BC Hydro team determined 2 MW of storage was required to mitigate the capacity risk at Golden substation. In locating 1 MW at Field and implementing an islanding scheme, BC Hydro expects to reduce the number of extended outages for the community by up to 80%.

The Start

As a crown corporation owned by the provincial government of British Columbia, BC Hydro is required to procure equipment and services through a competitive bidding process. The utility enlisted the help of Quanta Technology to develop requests for proposals for both the battery and systems integrator. Developing the selection criteria for the battery technology required meeting the reliability requirements of the organization. As a result, only the sodium-sulfur (NaS) battery technology, supplied by NGK Insulators, could demonstrate a proven track record with the battery size and function that BC Hydro required.

The utility chose S&C Electric as the systems integrator because it has successfully installed more than 12 MW of sodium-sulfur BESS. In posting separate requests for proposals for the batteries and system integrator, BC Hydro hoped to make the project open to a larger number of proponents; however, in retrospect, a single vendor proposal and contract would have been simpler to manage.

The biggest hurdles to completing the battery and system integrator contracts proved to be the standards definitions, generally boilerplate to the utility, with which the new technologies did not necessarily comply. For example, BC Hydro did not have a standard for a storage management system (SMS), so the utility included the Canadian Standards Association standard for small low-voltage inverters it had adopted. At the time, the inverter in S&C Electric’s PureWave SMS had not been certified to that standard so a waiver was required, although certification has since been achieved in a recent application in Canada.

Not having a full understanding of the requirements put the procurement team in the unusual position of looking to the proponent for guidance on the contract language while still protecting the utility’s interests. Completing negotiations for both contracts required all parties to proceed to the first level of design with a degree of cooperation and openness not typically seen during a standard procurement process.

Canadian Winters

The location, environment and climatic conditions in British Columbia’s East Kootenay region presented the team with a unique design challenge. Initial plans called for the NaS batteries to be installed in external weatherproof enclosures suitable for ambient temperatures as low as -40°C (-40°F). However, through a more detailed study of the climate in the proposed locations, potential temperatures of -50°C (-58°C) were considered possible. A revised plan for two climate-controlled buildings with the batteries in racks proved to be prohibitively expensive and almost ended the project before it had even started.

A third option, proposed by the systems integrator, S&C Electric, was to use the external battery enclosures installed inside prefabricated buildings. This solution would provide protection from snow and sufficient insulation for the internal temperatures to never to drop below -40°C. In addition, NGK modified the design of the battery module enclosures so all electronic components would be confined to one end of the installation where the ambient temperature could be further controlled. This revised design required input and cooperation from all stakeholders. Support from Parks Canada and Natural Resources Canada was invaluable to being able to fast-track an agreement to the process.

Telecommunications

For automated function and monitoring of the battery systems, telecommunications was required at both the Golden and Field sites back to BC Hydro operations, between the sites and the Golden substation, and between the Field site and the point of islanding.

In 2011, the communication options for the Field battery located in Yoho National Park were limited by available providers, terrain, climate and vegetation. Landline services were limited, there was no cellular infrastructure and the satellite links were not guaranteed because of steep valleys and heavy precipitation. Local wireless communication was difficult given the distances and pathway of the distribution lines through densely forested parkland. The challenge was to find an economic solution with acceptable reliability.

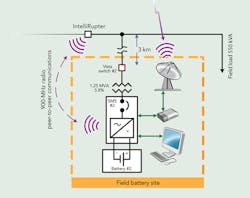

After much deliberation, the long-haul communication from the Field battery site to the Golden substation and back to BC Hydro operations would be provided by C-band satellite, and the short-haul communications, between the islanding disconnect point and the battery site, would be provided by a 900-MHz SpeedNet radio. The design of the radio portion required a fiber section from the site through dense forest to the open road and then multiple radio hops on two new poles to find a reliable signal path. Since the time of the original design, cellular communication has been established in Field and this option is now used by S&C and NGK to monitor their systems remotely.

Islanding

Each BESS consists of the NaS battery modules and battery management system, SMS (including the inverter and master control unit), transformer and isolation switches. For the Field system, an IntelliRupter PulseCloser provides the intelligence and point of isolation required for the islanding operation. A small propane generator is required for backup station

service.

The islanding function of the Field battery is enabled by IntelliTeam software running on the IntelliRupter and SMS to isolate the load and reroute the power supply. In the event of a fault between the Golden substation and the IntelliRupter, the upstream feeder protection opens to clear the fault and the SMS anti-islanding protection trips the battery unit off-line. The IntelliRupter detects a lack of upstream voltage, waits a preset amount of time to confirm the fault is permanent and then opens to isolate the portion of the feeder to be islanded. It then sends a signal to the SMS, causing it to close the main SMS breaker and start supplying power to the community of Field.

Customers experience a short outage during the switching, after which the battery provides power until either the system is restored or the battery is depleted. On system restoration, the IntelliRupter detects voltage on the upstream side and signals the SMS. The SMS again isolates the battery, causing another momentary outage for the customers before the IntelliRupter closes, allowing power from the grid to flow to the community. Another signal to the SMS initiates recharging the battery.

Peak Shaving

During peak-shaving control mode, the SMS can control the batteries based on either a scheduled charge and discharge cycle or input setpoints to the controller. To optimize the life of the batteries, BC Hydro contemplated developing an advanced control algorithm to charge and discharge the batteries based on measured load at the Golden substation transformers. The design would call for the peak-shaving control setpoints to be calculated at the Golden substation and communicated to the battery sites with default local control patterns should the communications links fail.

The battery located in Golden would be discharged based on a certain load threshold being reached at the substation, with the battery at Field only discharged at a higher, more critical level. Developing the algorithm was complicated by the load profile of the Golden substation, which shows long, shallow peaks not easily covered by a battery discharge and charge cycle.

In addition, the algorithm had to account for the possibility of an outage on the distribution line between Golden and Field. In this event, it would be preferred that the Field battery be in a fully charged condition and able to support the community load for as long as possible until the distribution from Golden was restored. The algorithm also would need to recognize maximum and minimum states of charge for the batteries and the preferred charging and discharging profiles to maintain the life of the battery. A regular-forced deep discharge and charge would be scheduled to confirm battery health.

The extent of definition and development required for this algorithm and control function was estimated as beyond what was possible for the team, and the decision was made to revert to the default scheduled charge and discharge cycle.

Construction and Learning

Despite its best efforts, BC Hydro’s inexperience with BESS and a lack of defined standards for required components meant extensive delays to the project. The team was forced to learn and innovate at every stage. In some cases, this meant backtracking or redefining when a process, procedure or standard thought to be suitable turned out to be inappropriate. Finally, 18 months after receiving the award for funding, construction began at both the Golden and Field sites.

By October 2011, the concrete foundations for the batteries had been poured at both Golden and Field, and the team expected to complete the installation before winter weather and snow conditions became too severe to continue. Construction of the battery enclosures was set to start when BC Hydro received notification from NGK that a NaS battery in Japan had caught fire. NGK recommended that BC Hydro suspend construction until the cause of the fire could be determined and the project was put on hold.

During the next six months, NGK and BC Hydro met several times to review the results of NGK’s fire investigation and the proposed design modifications to mitigate future fire risk. BC Hydro now faced the prospect of another 12 months of delay before the batteries could be in service. A review of the business case indicated the risk of overcapacity at the Golden substation had diminished because of several other upgrades to the system, so the utility decided to reduce the installed battery capacity from 2 MW to 1 MW.

The 1-MW battery system would be installed at the Field site. This change meant revisiting the original contracts before remobilizing construction teams. During this time, NGK showed the utmost integrity in working through the changes and was able to deliver newly modified battery modules in time for the summer construction window.

The final challenge came in preparing the system for operation. BC Hydro had no prior experience to draw on and initially treated the system as an interconnection to an independent power producer. However, that only worked to the point of energizing the site. For ongoing operation, the site had to be treated more like a substation with established operating and maintenance orders.

In Service

BC Hydro’s NaS battery installation is now in service in Field. The team will continue to monitor the performance over the life of the battery, however, the experience and knowledge gained through its deployment can be applied immediately.

Helen Whittaker ([email protected]) is manager of technology innovation in the office of the CTO at BC Hydro. She is responsible for BC Hydro’s corporate technology road map and manages projects demonstrating new and emerging technologies. Whittaker holds a bachelor’s degree in aeronautical engineering from Loughborough University in the United Kingdom and a MBA degree from Simon Fraser University in Canada. She is a registered professional engineer in British Columbia and a certified project management professional.

Companies mentioned:

American Electric Power| www.aep.com

BC Hydro| www.bchydro.com

Natural Resources Canada| www.nrcan.gc.ca

NGK| www.ngk.co.jp

Quanta Technology| www.quanta-technology.com

S&C Electric| www.sandc.com