Public Service Electric and Gas Co. (PSE&G) needed to know the condition of its underground network assets. The utility wanted to provide visibility for dispatchers, loadings for engineers and remote operability for its entire organization.

The concept was to bring actionable information to dispatchers and engineers by installing fiber communications networks, supervisory control and data acquisition (SCADA), sensors and microprocessor-based relay protection upgrades on all of PSE&G’s 26-kV underground networks in large urban areas.

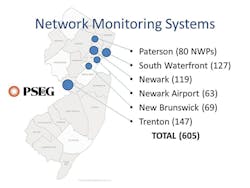

To date, PSE&G has installed a state-of-the-art fiber-optic network monitoring system (NMS) on six of its largest urban networks throughout its service territory. This system allows the utility to have real-time monitoring on its transformers and network protectors, as well as two-way communication and control of the network protectors.

A Comprehensive Approach

The project team developed solutions by using tools already in use at PSE&G. This approach provided the utility with an asset health tool that uses smart grid technologies through the network, including redundant high-speed communication channels.

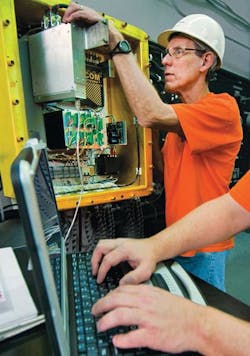

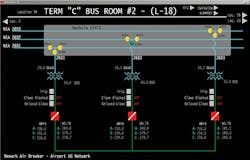

PSE&G selected Black & Veatch to provide full system engineering and integration from the field device in the underground transformer vault to the operator graphic displays that are part of SCADA. System components — including the remote terminal units (RTUs), microprocessor SCADA-capable network protector relays, all sensors, and submersible enclosures and connectors — were supplied by Electronic Technology Inc.

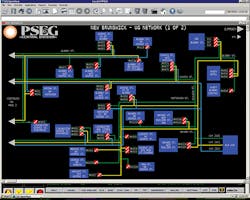

The system provides real-time status and condition of the underground assets, the loading on all transformers, operating data such as voltage and currents, operational control of network protectors and the location of cable faults. The project included the upgrade of transformer vaults with fiber communications and SCADA equipment. This provided remote monitoring of transformers and cable fault indicators, as well as control of network protector relays. The project also included the deployment of redundant fiber communications networks to all vaults.

PSE&G provided the physical resources to install the equipment and handled the financial control for the project. Black & Veatch and Electronic Technology Inc. provided the technical expertise and third-party support required to move the data from the field locations to the centralized control center for analysis.

System Health Monitoring

The RTU collects and measures the health of the system at both the transformer and circuit levels. It then transmits that data by fiber-optic cable back to a centralized location. From the centralized location, it goes to both the operations department dispatcher screens as well as an engineering desktop. This kind of network monitoring allows the utility to monitor, in real time, what is going on below ground. By installing this fiber communications network, PSE&G is able to process actionable information and proactively take steps to help prevent network outages or failures.

The system allows the PSE&G operations department to monitor remotely the configuration and loading on the network, and proactively take steps to prevent network outages or failures. The work was performed under the New Jersey Board of Public Utilities-approved PSE&G stimulus project from 2009 through 2011, improving service reliability.

The NMS project included adding a redundant fiber backbone, several hundred RTUs, more than 600 SCADA-capable network protector relays and more than 1,000 sensors. In addition, SCADA master station programming and display work was completed. The new equipment provides real-time information on network equipment status with a scan rate of every 4 seconds.

Achievable Expectations

The state-of-the-art system will enhance reliability and allow PSE&G to operate the system more efficiently. It also will provide savings in inspection and field visits. Installation of the system has made the network system more resilient and will provide more options to help shorten the duration of power outages, should they occur.

The system provides significant savings in crew time required for field checking of equipment either for status or loading. Not only is a trip to the equipment avoided, any preparation work such as traffic control or manhole pumping also is avoided. System screens allow easy monitoring of entire network areas and some data is configured to change color based on values.

The system includes a more rapid fault-locating capability, which helps to pinpoint where problems are, thus avoiding hours of randomly searching for failure location and associated pumping of manholes. This system results in quicker circuit restoration.

Network Protectors

One of the most significant uses of data is to identify backfeeding network protectors. A problem that occurs in any network system is when network protectors do not trip on backfeed. When a substation breaker is opened, either manually or automatically, the feeder does not immediately go dead since many network protectors are still closed. As soon as the breaker opens, power begins to flow backward through one or more protectors from the network grid. The network voltage is stepped up by the network transformer operating in reverse, keeping the feeder at or near the normal operating voltage.

Under normal circumstances, this reverse flow of power is detected by the protector relay, which then opens the protector. As the protectors open because of reverse power flow, other units start to see reverse power. In a properly operating system, this continues until all the network protectors are open and the feeder is dead.

If a network protector fails to open — due to a mechanical failure, malfunctioning relay or for whatever reason — the flow of reverse power continues to keep the feeder energized. Since the feeder is still live, conditions can exist that allow power to flow from the malfunctioning (backfeeding) protector along the feeder and forward-feed through another closed protector.

Since this relay is seeing a net forward power flow, it remains closed because the relay has no way of knowing where the forward power originates from, for example, a substation or a neighboring protector. This network protector remains closed in sympathy with the true backfeeding unit. Depending on system conditions, several network protectors can remain closed in sympathy, making it more difficult to track down the offending unit.

In some cases, it is possible opening one of the forward-feeding sympathy network protectors could cause the feeder voltage to rise enough for a relay in an open network protector to see the voltage difference (for normal power flow) and close the protector. Once the backfeeding network protector is located and opened, any forward-feeding protectors should start to see a reverse power flow and open, allowing the feeder to go dead.

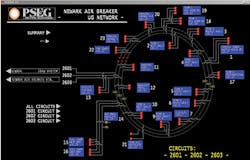

Clearing a backfeed situation used to take several crews up to an entire day. Each manhole had to be pumped down and inspected to see if the network protector was closed and, if so, whether it was backfeeding. Now, using a special screen developed for this purpose, the backfeeding network protector can be identified immediately. A crew can be dispatched directly to that location and clear the trouble.

Smart Maintenance

PSE&G is now looking to the next steps for analyzing data in new ways and moving to a more reliability-centered maintenance-based approach. The utility is developing algorithms to use real-time data in a more intelligent way and to allow the computer to continuously monitor information and alert engineers when changes are occurring.

All available information has been centralized in a computerized maintenance management system (CMMS). A process has been created for system alarms where subject-matter experts are notified immediately by e-mail for alarms received from the 26-kV network monitoring system. These alarms presently include the following: protector failed to close, protector failed to open, excessive protector operations, high/low protector case pressure, high kilovolt-amps (kVA), high/low transformer pressure, blown fuse, and backfeed alarm.

These alarms can be used to identify equipment operating differently than other similar pieces of equipment and to identify trouble as it occurs. Alarm algorithms continue to be refined as results are analyzed by subject-matter experts and followed up by the underground crews. Asset engineers have started meeting monthly to review algorithm results and determine ways to make the alarms more intelligent.

In addition, system alarm history is currently being logged to a relational database. This will allow the tracking of problematic equipment and determine equipment, circuit and network health. These alarms include the following: transformer load exceeding 100% of nameplate, protector voltage and current imbalance, excessive protector operations, backfeed alarm history, and transformer high temperatures and low pressures.

Additional displays have been created for each network and are available on the utility’s intranet, Microsoft SharePoint, throughout the organization: current, current phase angle, %kVA, %kVA of transformer to its normal rating, protector status, kVA trends, and one-line diagram of cable circuits with fault detectors and their current status.

Vendor engineers have been added to the CMMS alarm notifications and have been working closely with the division personnel to troubleshoot alarms. The investigations have revealed relay firmware updates, failed motors and bad resistor, burned-up trip coil, failed relay power supply and failed relays. Subject-matter experts and asset engineers continue to work with the divisions and vendor engineers on investigating alarms, correcting trouble and identifying trouble that could cause future failures.

Continuous Learning

Future plans include building an asset model of the underground network transformers and network protectors in CMMS, correlating the operation, diagnostic, maintenance and inspection data to the model, and building condition-based maintenance algorithms. PSE&G plans to build logic such that the system will alarm and indicate the location of faults. It also wants to learn from the system continuously to make alarms more intelligent as well as reports and displays more robust.

The utility also plans to integrate work order history, circuit operating data results, diagnostic tests (oil and backfeed), and alarm history into an algorithm that will identify the worst-performing transformer, protector and circuit.

Condition-based assessment algorithms also are being created for the utility’s network assets that combine historical data with circuit operation data to create a priority-ranked list of equipment to be inspected or replaced. This work will be ongoing and will take some time to implement fully.

This state-of-the-art fiber-optic NMS has positioned PSE&G to be ready to monitor and operate its networks well into the future.

David Blew ([email protected]) is the manager of outside plant at Public Service Electric and Gas Co. His responsibilities encompass all areas of technical support for overhead and underground electrical systems. He has more than 28 years of experience in power distribution including reliability analysis, asset management, standards and technical support. Prior to joining PSE&G, Blew commanded a U.S. Army Nuclear-augmented Explosive Ordnance Disposal Detachment. He also received a BSME with honors from Widener University.

Mentioned in this article:

Black & Veatch | www.bv.com

Electronic Technology Inc. | http://eti-nj.com/

Public Service Electric and Gas Co. | www.pseg.com