When electric distribution engineers discuss network operations, they typically talk about challenges related to retrofitting and upgrading substations and distribution feeders across networks. Like other utilities, NV Energy maintains and operates a combination of modern and older electric grid infrastructure constantly monitored and adjusted to meet the needs of customers.

The U.S. utility serves nearly 90% of Nevada’s population, which includes 1.2 million residential, business and industrial customers as well as a tourist population of more than 40 million annually. The utility considers substations and distribution power lines two of its most valuable assets to support customers. Receiving electrical flow data is crucial to provide the most reliable service possible.

Although comparative analysis in Edison Electric Institute’s system average interruption frequency index (SAIFI) and system average interruption duration index (SAIDI) puts NV Energy’s reliability in the top quartile of utilities nationally, it continuously strives to provide more reliable services to customers. Typically, that involves gaining better situational awareness of grid conditions using methodologies such as telemetry and other more traditional types of monitoring solutions.

The Traditional Approach

The problem is existing technologies used for monitoring distribution networks can take months or longer to implement. They often are costly and demand significant coordination across several divisions within a utility. For example, telemetering equipment involves the following:

• Extensive substation predesign work for metering and communications systems requiring coordination by multiple departments.

• Careful management of customers during the installation phase, in which planned outages may cause disruption of service, particularly for those located in remote areas where alternative power lines to provide backup may not be available.

• A full schedule of work for numerous line crews, which adds to the cost of equipment purchase.

A traditional approach to enhancing situational awareness is labor intensive. It often involves the use of paper-chart recorders or analog meters, and it requires personnel to drive to each substation to read data manually, record the information on spreadsheets and then share it with team members. The process can take several weeks to complete and has the potential for errors.

A New Approach

Dissatisfied with the costly and burdensome methodologies of traditional approaches, NV Energy — through its remote line sensor program — investigated possible monitoring solutions to retrofit substations and distribution feeders across its network. The solution needed to meet several criteria. It had to be cost competitive, quick to install and activate — without disrupting grid operations — and demonstrate clear benefits for NV Energy’s customers. Health and safety also were high on the utility’s agenda. With line work rated consistently as one of the top 10 most dangerous occupations, the solution also had to be safe for the utility’s linemen.

NV Energy decided to take a fresh approach toward obtaining accurate, real-time operating data. With such valuable information in hand, the utility would be better equipped to balance load, resolve power-quality issues, restore power more quickly during an outage and anticipate customers’ needs.

The utility opted for a solution that involved using a grid-monitoring platform. The solution, from Aclara, comprises inductively powered (battery-free) line sensors and easy-to-use software that provides predictive system analytics.

A Turnkey Platform

The turnkey platform from Aclara was simple to set up and easy to integrate across network infrastructures. It also is scalable and enables sensors to be upgraded over the air. The remote line sensors communicate with a software installation that either can be in-house or hosted by the manufacturer. A local Wi-Fi or broad cellular network provides the backhaul for the bulk data. The sensors, which are accurate down to 3 A, are clamped onto overhead lines using a hot stick or rubber gloves. A single lineman can install a sensor safely in just a few minutes. After the sensor is installed on the line, communications with the software begins automatically.

After installation of the sensors, the smart-sensor software with predictive analytics is set up. Using the software, network operators can aggregate sensor data with a single connection that can be aligned with a variety of available utility operating systems. This enables the system to classify network events and monitor grid conditions.

The software can be configured to send notifications by text message or email for crews to decide whether to investigate power-quality issues, potential equipment failures, network overloads, momentary outages or even line-disturbance conditions to improve service reliability. The technology provides real-time data to alert network operators to potential problems. NV Energy can stay one step ahead by being able to predict outages and locate major faults before they even occur.

Improved Service Reliability

Results of NV Energy’s initial pilot highlighted the dangers of not having near-real-time telemetry for remote substations and feeders. As soon as the sensors were installed, they began providing line condition data that was compared to manual and paper-chart data for the same facilities. It soon became apparent that data the utility had used for years was not accurate, illustrating the imprudence of a default practice of not testing, calibrating and maintaining legacy measuring equipment regularly. Through a process of checking and rechecking, it was determined the sensors erased many years of inaccurate readings either through misapplication of multipliers or detecting faulty measurement equipment.

One case involved a major customer complaining of voltage imbalances. The voltage monitoring solution serving this remote customer used an open-delta voltage-regulator system that had been in place for many years. The controllers for the system were upgraded and checked periodically.

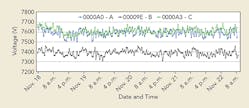

The output from the system led NV Energy to believe the imbalance was on the customer’s side of the primary service, a source of disagreement between the parties for many years. After the line sensors were deployed to monitor the voltage, it became clear the imbalance was on the utility side of the service. Troubleshooting began, and the utility determined the readings obtained at the voltage-regulator controls were incorrect. Once this was determined, a simple adjustment to the regulator settings corrected the problem. The customer’s concerns were resolved, and the service is now correct and verified in near real time using the constant stream of data the new sensors provided.

A Successful Business Case

NV Energy is now just over two-and-a-half years into its remote line sensor program, and the utility has added fault notification to the list of benefits that improve customer service. Because many of the line sensors installed are located in outlying and rural areas of the state, notification and reacting to outages has a built-in delay in response.

However, with the sensor’s automatic notification feature of the new system, utility trouble men located and living in these rural areas get notification from the sensor 5 minutes to 15 minutes before the control center can determine and notify them of a circuit outage. In several cases, trouble crew members have reported they were already on the scene when they received a notification from the control center, because the immediate notification of trouble from the sensor already had alerted them of the situation.

Because of this initial successful business case, which demonstrated true customer-related benefits, NV Energy expanded the deployment of smart grid sensors throughout its medium-voltage distribution network. The utility plans to install sensors at an estimated 300 locations over the next two years.

The Benefits of Sensors

The use of line sensors has worked for NV Energy for several reasons. First, the sensor technology easily integrates with the different platforms the utility uses, enabling the technology to be used for multiple applications. Second, once clamped on, the sensors immediately start sending data to classify power disturbance events in a visual format so crews can respond quickly to situations such as load planning, outages and faults.

Even with the best training and work practices in place, working with energized power lines can be hazardous. The more time and installation steps involved, site visits required and activity needed to rectify network problems, the higher the risk is for linemen and field personnel. Because of its design and ease of installation, linemen can deploy line sensors on live overhead lines and remain safe.

Implementing grid monitoring using more conventional equipment can be as much as 10 times more expensive than deploying smart grid sensors. The reason is traditional solutions require collaboration between numerous departments to design, construct and implement existing systems, while line sensor solutions require much less collaboration, which results in a significant reduction in the amount of project time and resources used to implement line sensors.

Load and substation monitoring were the first two applications on which NV Energy’s distribution planning department focused. Today, line sensor data is being shared with additional departments, including operations research and analysis, field troubleshooting and protection engineering, and distribution outage management. The data from line sensors gives these departments a better understanding of grid events, enabling teams to make informed decisions regarding appropriate actions. These actions ensure disruption to customers’ electricity supply is minimized.

This new distribution grid-monitoring platform has enhanced NV Energy’s ability to monitor its distribution network, substations and other assets as well as enabled the utility to react quickly to adverse conditions that would have gone undetected without this new technology.

Ron Kirker is a senior engineer in NV Energy’s distribution planning and distributed energy resource solutions. His current focus is on distribution-related energy storage solutions. Previously, he worked for several utilities and held positions in manufacturing and field applications ranging from centralized capacitor control, transformer corrosion mitigation and distribution automation.