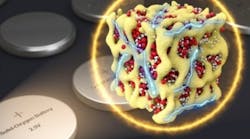

A recent breakthrough highlighted in Science Daily, describes MIT researcher’s new concept for battery cathodes, utilizing nanometer-scale particles made of lithium and oxygen compounds.

The new concept, called a nanolithia cathode battery, is described in a paper by Ju Li, the Battelle Energy Alliance Professor of Nuclear Science and Engineering at MIT. One of the shortcomings of lithium-air batteries, Li explains, is the mismatch between the voltages involved in charging and discharging the batteries. The batteries' output voltage is more than 1.2 volts lower than the voltage used to charge them, which represents a significant power loss incurred in each charging cycle. "You waste 30 percent of the electrical energy as heat in charging. ... It can actually burn if you charge it too fast," he says.

Overall, the new battery system is "very scalable, cheap, and much safer" than lithium-air batteries, Li says.

While the Science Daily article also states that the team expects to move from this lab-scale proof of concept to a practical prototype within about a year, it is worth mentioning that this breakthrough, and others like it, can require many years of subsequent work after initial successful prototyping, to develop economical manufacturing processes, and address numerous other challenges, before becoming fully commercialized.