The Smart Grid Investment Grant (SGIG) program, funded by the American Recovery and Reinvestment Act of 2009, was put in place to accelerate investments in grid modernization. The program makes available US$3.4 billion in federal funds matched with private-sector resources for a total investment of at least $7.8 billion. The Office of Electricity Delivery and Energy Reliability within the U.S. Department of Energy (DOE) is leading the grid-modernization efforts.

After the DOE conducted a competitive selection process, 99 projects in nearly every state received SGIG funds to demonstrate the benefits of a smarter grid. These projects bring together investor-owned and municipal utilities, vendors and research organizations to test technologies, streamline the implementation process and collect data on the realized smarter grid benefits. The projects were launched in early 2010 and are expected to complete equipment installation within the 2013-2014 timeframe. Data collection and analysis will be completed in 2015.

Florida Power & Light Co.

Florida Power & Light Co.’s (FPL’s) Energy Smart Florida, one of the largest and most comprehensive of the SGIG projects, illustrates the variety and multitude of transmission and distribution grid innovations being implemented as a result of the grants. Parts of the $800 million project werealready underway with the utility’s smart meters installation. The $200 million DOE grant allowed FPL to accelerate its plans and implement incremental improvements in transmission and distribution, as well as to undertake some pilot projects.

FPL worked with new and current vendors for the smart grid equipment and engineering design process. “The in-home technology products we installed through a pilot program and several sensor devices on the distribution side are still relatively new in the market, requiring new design, installation and operation processes, and not as mature as the products we installed on the transmission and substation side,” said Bryan Olnick, FPL’s vice president of customer service smart grid solutions and meter services.

“Our program has been about more than just installing the sensing and monitoring devices. We wanted to use the new sensing technologies to get a better understanding of how robust and capable the technology is, and how to bring the information back into our control centers and diagnostic centers to improve our operations and the services we provide our customers.”

FPL Scope

At the close of 2012, FPL had installed more than 10,000 smart grid devices on its transmission and distribution grid, installed 4.2 million smart meters and added some form of enhanced digital technology to all of its substations. The utility installed sensors and monitors on transformers, insulators, breakers and batteries to determine the health of the equipment and predict potential issues. In addition, FPL installed digital microprocessor technologies and updated transmission protection and control panels to provide real-time telemetry and enhanced reliability. These devices serve as key components of FPL’s wide-area situational analysis. Internally, FPL staff developed software applications to analyze the data coming into the predictive diagnostic centers. Engineers and operators use this data to pinpoint equipment problems so crews can be dispatched before outages occur.

The newly installed digital distribution equipment is connected through a wireless mesh network. FPL used the same radio network cards in both the smart meters and the distribution automation switches to fully leverage the network capabilities. The mesh radio technology also connects the newly installed capacitor bank system and thousands of other distribution grid sensors and monitors.

FPL Benefits

These distribution system improvements have produced measurable benefits already. For example, the utility’s upgraded Transmission Performance and Diagnostic Center (TPDC) remotely monitors power transformers in 500 substations. New bushing monitors, which detect and diagnose problems before they occur, have been installed on some of those transformers to evaluate the condition of both high- and low-voltage bushings, including capacitance, power factor and the extent of current imbalance.

Bushing failures can damage transformers, resulting in costly repairs and extended outages. In January 2012, a newly installed monitor detected an out-of-tolerance high-voltage bushing. Customers served by this transformer were temporarily switched to another one, and the affected transformer was removed from service. The faulty bushing was then replaced, preventing a potential outage that would have affected several thousand customers.

The TPDC also monitors battery banks that provide power to 500 substations. The battery banks are monitored for both high- and low-voltage levels, as well as high impedance. In February 2011, a TPDC monitor received an alarm signal indicating a battery problem at a substation located in a remote section of FPL’s service territory. A local field engineer was dispatched to the site, found a loose interconnection strap that caused the alarm and made the repair. This prevented a battery malfunction, which might have resulted in an extended outage for the hundreds of customers served by that substation.

FPL Lessons Learned

Olnick said FPL has learned valuable lessons through its smart grid project, which was nearly complete by the end of 2012. “FPL is known for its ability to execute on large-scale utility projects, and this was a huge project even for us,” Olnick said. “A smart grid project of this scale and innovation requires a supportive state regulatory framework and strong utility leadership. It also requires a lot of workforce and organizational preparation to implement all the new technology and procedures.

“We were required to rigorously evaluate the technology in our selection process,” Olnick added. “There were a few vendors whose products just weren’t there yet, so we had to find either alternative products or vendors. It takes a lot from the vendors when you are asking them to ramp up and produce a substantial amount of equipment in a short period of time, and to help engineer many complex projects. Companies like General Electric (GE) really came to bat for us, along with others like Silver Spring Networks.”

GE provided its engineering design staff to help FPL manage the large amount of engineering design work required in many of the substation equipment changes. “It takes working closely with your strategic partners to get the job done right,” Olnick said. “In addition, you must make sure that the technology you choose is both scalable and secure. In-depth and detailed testing was critical to ensure the new technology met our cyber security standards. You also must take time to analyze the system capabilities to make sure you can support the enormous amounts of data generated by all these devices.”

Sacramento Municipal Utility District

Sacramento Municipal Utility District (SMUD) is implementing its smart grid project, called SmartSacramento, to realize operational efficiencies and improve system reliability, as well as to test customer acceptance and participation in various dynamic pricing options. SMUD is one of 11 utilities conducting customer behavior studies designed and done in conjunction with the Lawrence Berkeley National Laboratory. Almost 150,000 customers from across the United States are involved.

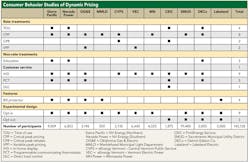

The utilities listed in the table above are evaluating different rates and customer systems in their studies. Most of the studies are assessing customer acceptance and response to time-based rates on an opt-in basis; a few also are testing opt-out options.

SMUD has installed all of its smart meters, and nearly all of the customers invited to participate in the customer behavior study have opted in, thus the SMUD project offers a good sample of the potential benefits of smart meters for both a utility and its customers.

SMUD Overview

From the early days when the industry was talking about the benefits of an intelligent grid, SMUD was looking at smart meters from an operational savings perspective to reduce costs in meter reading and disconnects. Receiving $127 million in federal funds just sped up the process of implementing SMUD’s $308 million smart grid project. The utility was looking for technology that would be flexible and scalable for the long term and used for the smart grid as a whole. By April 2012, approximately 626,000 Landis+Gyr smart meters were installed across the entire service territory.

A Silver Spring Networks radio frequency mesh network provides the communications infrastructure. The meters communicate amongst themselves and through access points with a backhaul. AT&T grabs the data at the access points and communicates it through SMUD’s firewall into the utility’s applications. As another component, SMUD selected the Itron Enterprise Edition Meter Data Management system to gather the data. In the past, the utility used monthly reads for all of its customers. Now, commercial customers’ meters are read every 15 minutes and residential customers’ meters are read once a day.

In the midst of doing the last meter deployments, SMUD changed its rate structure for 65,000 customers. “Before smart meters, in order to implement that change, we would have had to go out into the field with the optical port and reprogram all those meters,” said Erick Krause, project development manager for SMUD. “This would have taken years to complete. With the smart meters, however, it only took six months, and four or five of those months were spent developing the technology. This saved about $10 million in staff time.”

In addition to cutting costs in meter reading and field services, the smart readers provide 99.87% accuracy on readings, which has virtually eliminated estimations. With fewer estimations, there are fewer billing errors, which has greatly reduced the number of call center calls.

Only one-tenth of 1% of SMUD’s customers opted out of the smart grid program. For those few, their meters were replaced with non-transmitting digital meters. These can be used if SMUD offers a time-of-use (TOU) rate on a regular basis or if data needs to be collected.

“A key to the success of the program is that we installed the network before we installed the meters, which prevented a lot of billing issues,” said Chris Capra, SMUD’s spokesman. “We installed 80,000 meters in a customer acceptance period in a downtown area, a suburban area with rolling hills and a rural area. We didn’t do full deployment until we determined that the system would work in these three topographical areas. We also did double and triple checks to confirm the billing.”

SMUD Dynamic Pricing

SMUD is run by a board of directors rather than being an investor-owned utility, so the utility had planned to use its two-way digital meters for dynamic pricing from the start. The utility is using some of its grant money to conduct consumer behavior studies, done in conjunction with the Lawrence Berkeley National Laboratory, that look at customer attitudes and adoption trends for various pricing models. The focus is on the impact of customer response during peak hours and critical peak events.

The study involves 57,000 residential customers for a test period from June 2012 through September 2013. The analysis of the study will be available in 2015. The study will provide insight for SMUD as well as for other utilities wishing to leverage their advanced metering infrastructure to reduce peak. Three pricing structures are being studied:

- A TOU pricing overlay with opt in and opt out available

- A TOU and critical peak pricing overlay with opt out available only

- A critical peak pricing overlay with both opt in and opt out available.

The TOU rate is scheduled for 4 p.m. to 5 p.m. SMUD can call up the critical peak pricing up to 12 times per year. All customers have access to information through a web portal and some customers also are given an in-house display to determine how that impacts participation. Programmable thermostats are not offered as part of the program. The study was run in the summer of 2012, will run again during the summer of 2013, and then will be analyzed and the results reported in 2015. Approximately 10,000 customers out of 550,000 resident customers participated.

“We had more customer participation than we needed for a statistical sample,” said Rachael Huang, SMUD’s manager of customer strategies. “We did an extensive communication effort with customers and explained the smart grid technology to them. We regularly communicate now through e-mail, texts and the in-home displays to let them know when to reduce power. Overall, we communicated a positive message that here was a way that customers could control their energy costs. The marketing team did some innovative outreach, such as creating videos that showed customers how to cook in the hot summer months to keep electricity costs down. Next summer, we will perform an extensive outreach again to remind customers they are participating in the program.

SMUD Lessons Learned

Krause explained that focusing on customer engagement from the outset of the project was critical to its success.

One speed bump in the process has been using the in-home displays.

“The technology standards are still evolving on the in-house displays, so our customers were on the cutting edge of using the equipment, which has created some usage challenges,” Huang said. “Also, many customers requested the in-house displays, but not all are motivated to use it, so we are trying to determine how to encourage usage. As a whole, the study will show us which dynamic pricing models are most popular and effective. It also will show whether customers need the in-house displays or whether they can just get the information off the web. Lastly, we are learning whether customers need a test or e-mail reminder to shape their energy usage behavior.”

The project has posed technical challenges as the utility ensures the system is capable of managing such a large volume of data. The utility also is integrating its customer information systems, demand-response systems and metering management application to run together seamlessly, to support dynamic pricing.

One foundation of the program’s initial success has been the utility’s use of targeted websites. Each study participant’s portal is tailored to the pricing program in which they are participating.

The overall objectives of SMUD’s smart grid program are grid reliability, integrating renewables and increasing energy efficiency with a focus on customers that will provide information benefiting many utilities, particularly in the area of new pricing options.