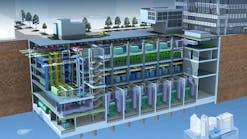

The 500-kV Tehachapi Renewable Transmission project in Southern California, U.S., will deliver renewable energy from Kern County, south through Los Angeles County and then east to the city of Ontario in San Bernardino County, a distance of more than 170 miles (274 km). The project, which replaced many of Southern California Edison’s (SCE’s) existing 220-kV lines with 500 kV, was all overhead except for 3.7 miles (6 km) of the line passing through the city of Chino Hills. While that portion represented only 1.5% of the total project, it created unprecedented engineering and construction challenges.

Although this project included just one circuit with two cross-linked polyethylene (XLPE) cables per phase initially, the final build-out can accommodate two circuits with three cables per phase for each circuit, or a total of 18 cables. SCE enlisted Black & Veatch as the engineer of record to handle detailed design, procurement and construction support to resolve the daunting electrical, mechanical and civil engineering challenges this project presented. Throughout the engineering, procurement and construction process, the SCE/Black & Veatch team worked closely and collaboratively with the various stakeholders, including Power Delivery Consultants and MPR Associates, as each new project decision arose.

This SCE underground project is the first installation of 500-kV XLPE cable in North America and the first time this type of cable was used in duct and manhole systems anywhere in the world. All previous installations were either in tunnels or direct-burial systems. None required the construction of duct structures on terrain with slopes between 30% to 40% in some areas, horizontal directional drilling (HDD) 150 ft (46 m) below the ground surface; 42 64-ft (19.5-m)-long cable splice vaults, or several miles of temporary and permanent access roads.

Cable Supplier

There were no cable standards in the U.S. or abroad that addressed the specific requirements of this project. Therefore, one of the project team’s first responsibilities was to generate underground cable specifications to present to potential cable vendors. Nothing was off the shelf, not even the cable specifications. The International Electrotechnical Commission (IEC) standard covers cable up to 500 kV, but it is only for normal steady-state operations, or cable conductor temperatures up to 90°C (194°F).

The IEC does not incorporate emergency operating requirements. For this installation, in planned emergency operations, the cable could operate at a conductor temperature of 95°C (203°F), which is 5C° (9F°) higher than the normal steady-state operation temperature. While the Association of Edison Illuminating Companies (AEIC) standard includes emergency requirements for operating temperatures above 90°C, they are only for cable up to 345 kV.

Black & Veatch and SCE engineers had to massage and blend elements of the two existing standards to come up with a cable specification that met the requirements of the project. Initial studies determined the cable system needed to have a minimum 5000-kcmil conductor with XLPE insulation; beyond this, SCE looked to the cable vendors to develop the final design.

The cable system needed to handle the circuit ampacity of 2000 A for normal operation and up to 3500 A for emergency operation, and capable of operating in extremely hilly terrain at depths of more than 100 ft (30 m) and in duct banks. The design also needed to incorporate integrated distributed temperature monitoring system of all the cables and a real-time partial-discharge monitoring system.

Once the project cable specification was finalized, a request for proposal was issued. SCE received up to six viable but different proposals from cable vendors all over the world. During the ensuing evaluations, many factors were considered beyond the technical evaluation of the cable system. These factors included prequalification and type test record, manufacturing and installation experience, manufacturing capacity, commercial evaluations, installation plans, safety and environmental plans. In the end, Taihan Electric Wires from South Korea was awarded the bid.

Protecting the Cable

The team worked with Taihan to finalize the cable design. Many design issues needed to be addressed, including the thermal-mechanical forces the system would experience. This issue quickly became a central component of the entire design. SCE was familiar with these forces in lower-voltage circuits it had designed and installed but at much smaller cable sizes. The cable specifications for this 500-kV line had an outer diameter of more than 6 inches (152 mm) and would weigh approximately 26 lb/ft (3.6 kg/m).

The design of a cable support system for a cable of this size would take some innovative engineering analysis; the XLPE cable system was modeled using a finite element analysis (FEA) approach based on work performed by the Electrical Power Research Institute. For simplification of modeling, the multi-layered cable core was modeled as a beam with material properties directly derived from mechanical tests Taihan performed in its factory. The results of the analysis would be used as a comparative check on the cable support system designed independently by Taihan engineers.

The team performed the FEA in three phases to determine the preferred design for the cable support system, which restrains the cable and splices inside the vaults and at the termination location in the transition station. Phase 1 focused on analyzing the cable thermal expansion and contraction without restraints. In phase 2, cable racking design information provided by Taihan was added to phase 1 results and a sensitivity analysis was performed on different cable system design parameters. With this information, engineers could determine the effect of different design and installation parameters on overall cable system operation, which, in turn, enabled them to develop an optimal design. Phase 3 focused on investigating the seismic effect on the thermal-mechanical performance of the cable system. Results indicated cable expansion during a seismic event would be unlikely to exceed the maximum allowable cable movement incorporated in the design of the proposed racking system.

The need to build in such rigor on the cable support system was driven by the unknown forces the cable system would experience, because thermal-mechanical loading criteria were not well understood or addressed. Put simply, the cable system was not viewed as a static component but rather a moving object with a copper core that expands and contracts with changes in temperature.

When installed, the cable would be at an ambient temperature of approximately 20°C to 30°C (68°F to 86°F). However, during operations, the copper core itself could regularly see temperatures as high as 95°C (203°F). This large temperature delta creates large linear expansion in the cable and, in turn, potentially large forces on the cable support system. To address this concern, the project team integrated a cable restraint system that enabled the cables to lengthen as much as 16 inches (406 mm) into each splice vault with the use of a flexible restraint system.

The cables would be trained into the vaults through an S-bend that effectively would function as a spring, enabling the cables to expand and contract with changes in temperature. The amount of growth and forces the expanding cables might produce were modeled in the FEA to help validate the extent of the S-bend and the strength of the cable support system.

Restraining the cables along the route where they traverse steep hills also required special attention. Because of the flexible restraint systems in the vaults, the splices were not capable of restraining cables to fight gravity and slide downhill. Therefore, at six locations along the route, purposely built restraint vaults were designed to anchor the cables from movement.

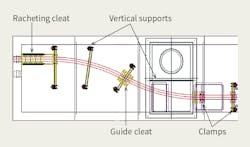

The restraint vaults were filled mostly with cable cleats designed to grip the cables. The splice vaults then were free simply to handle the cable splicing function without additional cable loads. Another innovation incorporated into the splice vaults were spring-loaded cleats attached to the end walls of the vaults. The purpose of these cleats was to restrain the cable’s growth partially into the vaults and provide additional load to force the cables back out of the vaults.

The design of the splice vaults themselves was another significant challenge. The project team had to add significant length to the vaults because the flexible restraint system incorporated the S-bend as the cables enter on one end and leave out the other. Unfortunately, this design detail was not developed before the final order was issued to the concrete vault fabricator. The original vault lengths were only 32 ft (9.8 m) long, but the final vault length grew to 64 ft (19.5 m) long. However, this additional length could be incorporated into the final design because of an innovative tunnel-section design used.

Early in the design process, the team realized the final vault lengths would be difficult to determine because the cable vendor had not been chosen yet. To address this unknown, the team incorporated a universal-design methodology wherever variability in cable criteria could impact other project components, such as the splice vault dimension. The vaults were designed as modular tunnel sections that would be assembled on-site. This provided flexibility for the vaults to be lengthened depending on the requirements of the selected cable vendor. The modular design also aided in delivery logistics, as a single tunnel section weighed significantly less than the fully assembled vault.

Access Roads and Duct Banks

While the cable engineering and testing was underway, Black & Veatch and its subcontractor, Webb & Associates, began the civil engineering portion of the project. Permanent roads were required for access to all splice and restraint vaults, in addition to miles of temporary roads, which were needed immediately to build the duct banks and provide down-line access for construction equipment.

In all, the project required some 17,000 linear ft (5180 m) of duct bank, which consisted of 7.5-ft-deep by 7.5-ft-wide (2.3-m by 2.3-m) trenches into which crews set 12 8-inch (203-mm)-diameter conduits for the XLPE cable (two layers of six). All the cable conduits — for power, ground, fiber-optic telecommunication cables and wires for partial-discharge monitoring — were held in place by cable spacers until the entire assembly was encased in thermal concrete.

Horizontal Directional Drilling

At two locations along the transmission line corridor, Black & Veatch engineers decided to employ HDD to install the conduit system under existing structures and topographic features. In all, the team designed a total of nearly 3 miles (4.8 km) of 36-inch (914-mm)-diameter HDD runs at two locations along the narrow transmission corridor. The first location crosses under a 60-ft (18.3-m) hill and a flood-control channel. The HDDs paralleled each other in a 3-wide by 2-tall configuration. This is expected to be the thermal chokepoint for the entire underground circuit, meaning the cables would run hottest in these HDDs. The second location also crosses under a flood-control channel.

The work, which began in late 2014 and continued through December 2016, required design considerations related to the following:

- Cable ampacity. Because the cables were designed to run at a steady-state temperature of 90°C throughout their 40-plus-year lifetime, the mutual heating of cables in six parallel HDDs in a relatively confined space became a key design consideration. As such, the engineering team performed extensive cable ampacity calculations to design a drill path for the HDDs that would meet the line rating requirement without the addition of an expensive forced cooling system.

- Drilling tolerances. If a drill bit wandered 5 ft (1.5 m) off the design path, the engineering team needed to know how that would affect ampacity.

- Grouting the bores. The engineering team also needed to know whether HDD bores should be grouted to prevent their collapse and the resulting surface settlement, and to provide the cables with a thermally favorable environment. Grouting the HDDs would alter the design and increase the complexity dramatically. The team decided there was no significant value in grouting.

- Alternative drilling paths. Determine whether another path would be available if the drillers were unable to complete an HDD and had to start over.

Transition Stations

The two transition stations, each about 3 acres (1.2 hectares) in size, constituted major civil engineering work on their own. Because of the hilly terrain, the Western Transition Station required approximately 170,000 cubic yards (130,000 cubic m) of cut and 60,000 cubic yards (45,000 cubic m) of fill. The Eastern Transition Station involved the demolition of old buildings and hazardous contamination remediation. Key features of both stations are the cast-in-place concrete cable trenches, which were designed to relieve mechanical stress in the cable terminations by enabling the cables to expand freely into the trenches.

Success

Throughout the three-year engineering design process, the team made all decisions with a strict emphasis on safety, constructability, schedule, maintainability and electrical performance. With input from numerous stakeholders, the overall project was so successful because of the collaboration from the various organizations involved. They have much to be proud of in building this first-of-its-kind transmission line.♦

Acknowledgements

A project of this magnitude and complexity requires countless talented individuals to manage and design. The authors would like to thank team members from the following companies for their expertise and dedication to the project: Southern California Edison, Black & Veatch, Webb & Associates, Power Delivery Consultants, MPR, Burns & McDonnell, Cable Consulting International Ltd. and HDR.

Roman Vazquez III is a senior project engineer for Southern California Edison. He served as manager of the engineering group for the Tehachapi Renewable Transmission project and is a licensed professional engineer in the state of California.

Hunly Chy is an engineering manager at Southern California Edison, overseeing the center of excellence for underground cable, which is the utility’s competency center for all things cable and wire from 600 V to 500 kV. He holds BSEE and MSEE degrees from California State University at Los Angeles and an MBA degree from the University of La Verne, and is a licensed electrical engineer in California.

John Rector is an associate vice president and a senior project manager with Black & Veatch, and served as the project manager for the 500-kV underground project. Rector has 40 years of experience in the industry, led Black & Veatch’s underground and overhead design group, and was one of the authors of the Electric Power Research Institute’s Green Book. He holds a BSEE degree from Kansas State University and is a registered professional engineer.

Ian Grant is a senior project engineer at Black & Veatch and was responsible for civil design on the underground project. Grant has more than 14 years of experience in underground transmission and substation civil projects. He holds a BSCE degree from the University of Portland and is a registered professional engineer.

Forest Rong is an engineering manager with Black & Veatch and the process owner of underground transmission business process. Rong has 23 years of experience in underground and underwater transmission industry. He holds a BSEE degree from Harbin Institute of Electrical Technology in China and an MSEE degree from McMaster University in Canada. He is a registered professional engineer in the U.S. and Canada.