Utility engineers normally do not have the luxury of picking the perfect project. Ironically, it is emergency projects that prove the value of advance planning and developing innovative solutions — for example, combining micropile designs and above-ground grillage assemblies for an effective and environmentally less-invasive foundation strategy. A landslide at an isolated location in Virginia’s Blue Ridge Mountains provided an opportunity to test this concept.

Several years ago, Dominion Energy made a corporate decision to pursue alternative foundation designs and construction concepts. The utility was looking for compact designs that would reduce the overall installation footprints for projects in remote, mountainous terrain deemed sensitive for environmental permitting. The new designs also needed to minimize access road construction and concrete delivery to project sites.

Environmental permitting is a huge factor in building out utility infrastructure. Projects simply cannot be done the same way as 30 years ago. Even though design and construction practices evolve constantly, government oversight is becoming more critical of what utilities consider standards of practice. The collective goal is not just to provide reliable electric service to customers but also protect the area’s existing natural resources.

Long-Term Planning

In the summer of 2021, Dominion was a year and a half into planning and designing 115-kV transmission lines from the Balcony Falls substation to the Skimmer interconnect in the Roanoke, Virginia, U.S., area. This mountainous 10-mile (16-km) line was originally constructed almost 100 years ago with wooden H-frame poles.

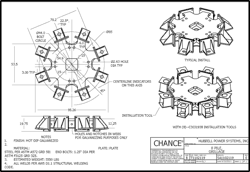

The utility was well into the design process with the vendor, Hubbell Power Systems Inc., on a fabricated steel-pole base. The foundation concept was a unique combination of micropiles and an above-ground grillage. Two load tests were performed and the geotechnical conditions were deemed favorable for successful installations.

Even though the two situations were not altogether similar, the general parameters of the two installations were close enough to consider using the fabricated pole-base design. The utility found surplus steel poles in storage that met every design and construction requirement. The emergency site would serve as a pilot project for the micropile-grillage foundation concept.

Micropile-Grillage Pole Base

Structural framework designs for pole foundations are often used in areas with soft soil, which offers low load-bearing capacity. One or more tiers of wood or steel beams are connected to distribute the load over a wider area. Sometimes called a grillage, they are normally buried in the ground. Typically, above-ground grillages are secured to the soil with helical piles. Each pile has a central steel shaft and several helical plates, screwed into the ground like a wood screw. Helical foundations can go 5 m to 15 m (16 ft to 49 ft) deep. This design uses much less concrete than drilled shaft foundations and is commonly used in remote or difficult-to-access areas with poor soil conditions.

However, helical piles cannot be used in rock, which is where drilled and grouted micropiles come into play. A machine drills a hole with a diameter under 12 inches (305 mm), hence the term “micro.” In the center is a bar with an expendable tip. The drill head stays at the bottom, and the hole is filled with high-strength cement grout.

Micropiles use the rock itself for the foundation. The center bar transmits the load to the bearing rock. This solution is considered a friction foundation, with the grout bonded to the rock. Micropiles can be placed at an angle and provide greater load capacity. They can be used as direct support for smaller structures or as part of larger ground reinforcement.

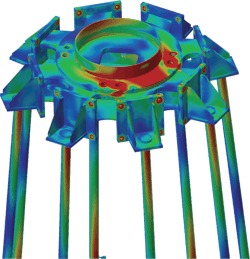

Connecting micropiles to a grillage is not a common strategy. However, it can serve as a workable solution for mountainside locations. The initial concept for the Dominion project used eight micropiles arranged in a circle around the grillage, and 3-D models were used to analyze stress conditions and deflection in the grillage when subjected to load — enabling the utility to further refine the design before making final production drawings.

Value Of Collaboration

Consistent partnerships ensured a practical approach and ultimately facilitated successful projects. Dominion already enjoyed a good working relationship with the grillage vendor. Although Hubbell had worked extensively with helical piles, the company had less experience with micropiles. Dominion’s engineering and construction staff had confidence Hubbell’s considerable grillage experience would result in an effective design.

The engineering collaboration set the project apart. The Dominion engineering team used the Hubbell engineering team as a sounding board for developing solutions. Schnabel Engineering performed the geotechnical engineering and micropile design, and Technical Foundations Inc. was the installation contractor. Working with experienced vendors provided consistency to the project. A collaborative, uniform design required less evaluation work, and it was easily modified for other conditions. The landslide site installation displayed this flexibility; the grillage was easily adapted for this project even though the design was originally intended for another site. Once the design was set, the order for the grillages went through Anixter International Inc. The micropiles used standard parts, sourced separately. The steel poles were already in stock, which was key to a timely response.

Using helicopters to bring in equipment was considered, as their high cost can sometimes be absorbed into the overall project cost. However, several factors made it more practical to proceed with standard road building for this particular location. The drilling equipment, concrete and poles were all trucked in.

Results For The Future

The installation ran into an additional challenge. While rock makes for a solid foundation, it can be an unknown. The landslide site rock was high in quartzite. Quartzite is much denser and heavier than the test sites were, which slowed down drilling.

Despite challenges and delays, three new micropile-grillage pole bases were safely set in December 2021.

Every issue the teams faced offered opportunities to develop solutions. The engineering collaboration was fruitful. Dominion always seeks the optimal place between design and cost, and the landslide project ended up being the proof-of-concept trial for the micropile-grillage arrangement. This innovative design will potentially save the utility time in upcoming projects.

A second project, involving about 40 micropile-grillage pole bases, is under consideration for use in late 2023. This project will incorporate the lessons learned from the landslide project to develop protocols. For example, performing full-scale load tests on the site rock will provide essential information to drilling teams. Adjusting the micropile designs based on each site’s subsurface characteristics will allow for optimal installations. Detailed specifications for installing micropiles are currently in development.

From One-Off To Off The Shelf

The results of the landslide emergency remediation helped Dominion’s engineering team to learn how to improve future designs. The collaborative effort spent in planning this project will save the utility time and money in the future. Dominion’s goal is to develop a permanent solution to handle both emergencies and projects with major environmental constraints.

The utility hopes to develop a family of designs that can be successfully applied across a range of applications and conditions. The grillage concept used on the landslide project offers the flexibility to handle a variety of settings. This approach helps to keep the power on for customers while being sensitive to the concerns of all stakeholders. Compact concepts like the combination micropile-grillage pole base have the potential to deliver.

John R. Klotz, P.E., ([email protected]) is a consulting engineer with Dominion Energy. He holds a BSCE degree from Virginia Tech. He serves on several American Society of Civil Engineers Structural Engineering Institute committees. He also has contributed to Electric Power Research Institute Inc. projects on groundline corrosion and vibratory caisson foundations.

For More Information

Anixter | www.anixter.com

Hubbell Power Systems | www.hubbell.com

Schnabel Engineering | www.schnabel-eng.com

Technical Foundations, Inc.

https://technicalfoundations.com