Electric utilities must not only operate aging lines and equipment at higher levels, but they must also adhere to technical, safety and reliability requirements. For example, five years ago, The North American Electric Reliability Corporation (NERC) began advising utilities to consider actual field conditions when verifying facility ratings. In turn, many utilities have surveyed transmission lines to identify critical issues and determine whether or not hardware components can handle high operating temperatures.

After reviewing clearance reports and conducting in-depth analysis, utilities often immediately derate lines to bring the line rating into compliance. Next, utilities replace all single-die compression dead-ends and splices with two-stage connectors to recover the line’s emergency rating, which can result in a specific maximum conductor operating temperature.

Depending on line length, utilities must replace dozens or even hundreds of compression dead-ends and compression mid-span splices. Field crews not only will have to work on a tight schedule, but they may not be able to obtain a clearance to de-energize the lines. Circumstances may require a utility to fund spinning reserve from another source to accommodate the outage if the duration of the transferred load exceeds the emergency rating of the alternate transmission line. To circumvent these challenges and save time in the field, AIR2, an airborne power line contractor, has helped utilities to install ClampStar shunt technology from Classic Connectors via helicopter.

Evaluating Alternatives

Before installing the shunt technology, utilities primarily replaced all single-stage splices and dead-ends with two-stage compression connectors. However, there are several concerns with this method. First of all, utilities may face challenges completing the project on time at a reasonable cost because of the number of connectors requiring replacement. Also, companies may face reliability concerns over the introduction of two potential “weak” points in the line because replacing a single mid-span splice typically requires two new splices plus a length of conductor in its place.

Linemen also must spend extra time on the dead-ends because they must remove a length of conductor. To maintain existing tensions, extra conductor and another splice is required or the insulator assembly has to be lengthened, thus requiring the jumpers to be lengthened.

Utilities must decide whether to perform the work with the line de-energized or energized because of the system load. In order for the work to be performed with the line de-energized, utilities may need to conduct significant temporary work to ensure all tap lines could remain energized during construction.

In many cases, utilities often opt to work the lines energized as well as from a helicopter for several key reasons. For example, in environmentally sensitive areas, utilities must mat or bridge wetlands and streams to gain access to the structures or splices. Also, by using traditional ground equipment rather than helicopters, utilities must discover a way to traverse private properties to gain access to the right-of-way. It’s not uncommon for a landowner’s path to provide the only feasible access to a structure, and in these situations, workers may have to rebuild a bridge to safely accommodate the weight of a line truck.

Finally, the heights of many of the dead-ends and splices could be over 100 ft aboveground with uneven terrain below, making some of the locations nearly impossible to reach safely from a truck. As such, working from the ground can quickly evolve into an expensive option requiring extensive coordination efforts, making the use of a helicopter a more viable option.

Installing Shunt Technology

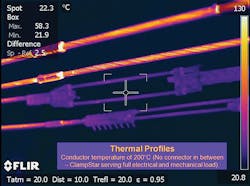

Given the numerous challenges accompanied by the drawbacks of a splice and dead-end replacement option, investigating the use of shunts is a logical alternative. Many utilities have never used shunts on a permanent basis before. However, the ClampStar shunt provides an excellent solution for permanent mechanical and electrical upgrade to existing conductor connections. The ClampStar shunt is made up of two sets of clamping ends, which secure to the conductor with bolts and shear nuts, with two strands of conductor in between. Classic Connectors designed the shunt to have a total resistance less than the main line conductor and splice combined. With this configuration, the ClampStar shunt is not only able to redirect the current such that the splice never experiences temperatures greater than ambient, it also restores the mechanical integrity to its original strength, preventing future mechanical splice failure.

In addition, the dead-end-style ClampStar shunts are equipped with a tether device that provides a robust mechanical restraint, which will keep the line in the air should excessive loading occur at the dead-end. The capabilities of the ClampStar shunts offer numerous advantages, especially when installing them from a helicopter. Not only does this option remove any required erosion control or other environmental preservation measures, but it also eliminates other logistical nightmares associated with trucks and allows for the lines to remain energized, significantly reducing the length of the construction schedule and lowering overall cost.

Saving Time

Most ClampStar shunts have an installation time of less than 10 minutes and can be installed on an energized line with a hot stick or live-line barehand crew. Despite the higher material costs of the ClampStar shunts versus the splice and dead-end materials, ClampStar shunts installed by helicopter will typically decrease most construction time by 70% to 80%.

Case in point: On a recent uprate project, AIR2 forecasted that it could complete a three-month job in four weeks. The lines were primarily built on double-circuit H-Frame and self-supporting single-pole structures with vertical configurations. Both lines use 1590 kcmil 54/19 ACSR (Falcon) conductor and were originally designed with sufficient clearance for a max operating temperature of 148°C (300°F). The program began with the helicopter crew installing the mid-span shunts with two linemen working off a platform attached to the helicopter. On the first day of this project, the linemen installed 22 mid-span ClampStar units with a typical average of six minutes per location. After the second day, all 39 mid-span splices were completely shunted.

Installing the dead-end shunts, however, was a bit more involved. AIR2 installed these units at an average rate of 30 minutes each. To perform this work, the helicopter positioned two linemen at the structure to work off ladders supported by the conductor.

Despite stringent project requirements and calendar limitations, AIR2 was able to install 147 dead-end and 39 mid-span shunts in just 19 days, which was less than a third of the originally allotted time frame for construction. Ultimately, the proficiency of the AIR2 crews, coupled with the ease of the ClampStar shunt installations, drove the project to completion well ahead of the deadline.

By installing ClampStar shunts, AIR2’s helicopter crews are helping utilities to deliver projects well ahead of schedule, save significant expenses relative to other alternatives and avoid de-energizing critical lines. In addition, this work practice is improving safety by minimizing linemen’s time in an energized environment and enhancing efforts to provide affordable, reliable and clean energy to customers.

With the ClampStar units installed, these connectors will not be subjected to additional temperatures, which would degrade them. The shunts serve to carry the current, and any remaining tension requirements of the conductor. The line will therefore be uprated for higher current capacity, and depending on the condition of the conductor, provide an additional 30 to 50 years of available service life to the line.

Mark Camus ([email protected]) is vice president of operations for AIR2, LLC.

Sidebar:The Effect of High Temperatures on Conductors

Single-stage connectors were originally designed for a maximum continuous operating temperature of 75°C (167°F). According to recent studies and long-term tests by internationally recognized research facilities like Electric Power Research Institute and Oak Ridge National Laboratory, this type of connector can be considered high risk when operated at temperatures as low as 125°C (257°F).

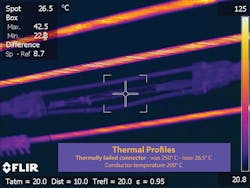

Manufacturers of these types of connectors recommend that they not be operated on lines above 93°C to 100°C (200°F to 212°F), because temperatures above this level subject the connectors to annealing, resulting in a loss of a significant portion of their tensile strength. To examine conductor life and hardware components as they relate to the high temperatures, utilities can use high-definition cameras. In turn, they can produce both still shots as well as video from the airborne platform and take both visual and infrared images, which allows the utility to identify trouble spots.

Taking the infrared images is particularly critical with aged lines, those 30 to 40 years of age or older, because the design life of the connectors used at that time was intended to be no more than 30 years. Furthermore, transmission lines built before the year 2000 used connectors with thermal limitations of 75°C, and as such, they are not suitable for temperatures typical for emergency ratings of any duration. The inhibitors used at that time were mineral oil-based and not intended for higher temperatures. Therefore, when a utility performs an analysis of aged lines, or any built before the turn of the century, they must pay particular attention to connectors.

Through this analysis, utilities may learn that although the clearances and conductor could probably handle the elevated temperatures, components such as single-stage compression dead-ends and splices are quite often inadequate. Using shunt technology successfully addresses these inadequacies by providing an excellent mechanical and electrical solution for line uprate projects. When combined with helicopter installation, electric utilities can avoid de-energizing lines and save considerable installation time translating into lower costs and higher reliability for end users.