In the late 19th century, telegraph poles were converted into transmission line structures to carry a new product called “electricity” to consumers. The 20th century saw a massive technological effort to develop those primitive transmission poles into structures capable of handling higher voltage levels to transport more power as demand increased. Fabricators also experimented with new ingredients added to traditional materials and new elements coming from the laboratory to offer a broader inventory of structures. The result was the ability to deliver customized towers and poles to transmission line designers as they struggled to meet new challenges.

With the dawn of the 21st century, the industry upped the ante by integrating all sorts of hardware and software technological applications into transmission and distribution lines. The quest has been to improve power delivery, reduce costs and squeeze every last megawatt out of the past, present and future transmission infrastructure. The big question is, where will all of this technological integration lead the poles, towers and pylons? Probably the best answer to that question comes from Chinese philosopher Confucius, who said, “Study the past, if you would define the future.” The electric utility industry is an excellent example of that statement. The founders had a pretty good handle on how to deliver electricity to the customer and how to make the system work, but they were limited by the technology of the day.

Over the past century, however, advancements in materials science have turned concepts into physical innovations, and the process and progress continues today. A lot of pressure is being put on the future transmission system to redefine how bulk power is moved across the grid as electricity moves toward being a commodity. Some experts say transmission lines are a thing of the past; others predict future transmission and distribution lines will not resemble anything the industry is currently familiar with today. Whatever happens, it is going to be exciting.

Dusting Off Old Ideas

Technological advancement is not always about new discoveries. It is usually about steady progress, hard work and the improvement of existing technologies. Direct current (dc) started this industry, but it had serious limitations compared with alternating current (ac), which soon replaced it. While dc was not forgotten, it was not mainstream, either. When solid-state devices became available in the middle of the last century, it did not take long for engineers to adapt dc technology to transmission systems. Suddenly, what was considered a niche market became a key element on the grid.

Today, high-voltage direct current (HVDC) has been integrated into ac grids worldwide, with HVDC transmission carrying thousands of gigawatts over thousands of miles. ABB, Alstom and Siemens report several benefits of HVDC, such as the ability to direct exactly where the power goes and lower losses, but one feature attracting attention is increased power transfer. Because of these attributes, schemes to convert ac transmission lines to dc are under investigation.

This is an attractive proposal in areas where transmission rights-of-way are limited, nonexistent or extremely congested. Proponents point out insulators will need to be replaced, but no additional structures will be required. They also say the existing structures and conductors can be reused in most cases, which is important for the utilities. The loadings from the conductor are the same after the conversion. ABB reports that converting one 400-kV ac transmission line to ±400 kV increases the ability of transferring power by more than 1000 MW.

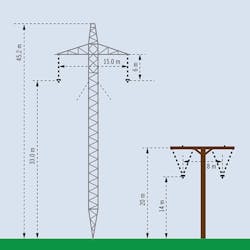

If conversion is not attractive, there also is a proposal to design compact ac and dc transmission lines. CIGRE’s Study Committee B2 (SC B2) on Overhead Lines met in Paris, France, this year to discuss the latest advancements in overhead transmission lines and heard a presentation by Dennis Woodford of Electranix and Lionel Barthold of IMod Inc. on the advantages of low-profile, compact HVDC transmission. The system presented to SC B2 was a ±500-kV compact dc transmission line capable of a 3800-MW thermal loading.

Without going into a lot of detail, the compact design took up the same right-of-way as a 69-kV ac line. The compact design was ±320 kV with structures approximately 20 m (66 ft) in height and 8 m (26 ft) in width (conductor-to-conductor) versus a ±500-kV design with structures approximately 45 m (148 ft) in height and 15 m (49 ft) in width (conductor-to-conductor). The authors pointed out the compact design used more structures, but they were much smaller with less visual and environmental impact. SC B2 received approval for CIGRE for a working group to investigate compact dc transmission.

Out of Sight

Another technology attracting attention for future potential is underground cable transmission. This technology also started out as the first-choice technology for the early electrical distribution systems, but the insulation technology of the day was not up to the challenge. It faulted repeatedly when energized and was quickly replaced by overhead transmission, but the concept was recognized as having potential. Today, the insulating materials have improved to the point cable systems are a major alternative to overhead transmission in environmentally sensitive areas.

Lately, utilities are experiencing a great deal of pressure to underground new transmission. It has become a key subject of many discussion and panel sessions at industry conferences, with many experts predicting the future of transmission will be completely underground. There is no denying underground circuits are attractive for environmental or aesthetic reasons, but cost is still a driving element, plus repair time is staggering when compared with overhead circuits.

Still, proponents of undergrounding continue to cite trends taking place in Europe and Asia. There are areas with high population densities that have overhead rights-of-way costs that are about the same as the cost of undergrounding a circuit. It is called being cost neutral and it’s having an effect on the infrastructure.

In Perspective

Sometimes a technological breakthrough puts a sacred cow on the path to extinction. Smart grid technology has placed arrays of sensors into just about every apparatus produced for the grid, which gives them the ability to be self-monitoring. It did not take long until someone got the bright idea that installing sensors directly onto transmission towers and poles would be useful in solving an age-old problem for transmission lines: capacity ratings.

Back in the day, the industry defined the capacity of transmission lines based on published values taken from charts, graphs and tables for conditions such as conductor sag, conductor temperature and weather conditions. More than 100 years later, this best-guess system is still being used to determine how much electrical power can be pushed across the grid, but a better way is available. Thanks to recent hardware breakthroughs, it is possible to collect real-time data for the actual physical conditions taking place on the right-of-way.

Old-school technology was not capable of monitoring all the variables needed to tell the operator what was going on for the entire length of a transmission line, much less the network, but that has changed with the advent of smart grid sensor technology. Research and development (R&D) has infused these components into the towers and poles, making them more than just support for the conductors; they are the next generation of smart structures. These structures are capable of measuring the sag of conductors, recording the temperature of conductors and reporting on weather conditions, but the data is not as useful without software to digest it.

Fortunately, manufacturers have married powerful software programs with all this hardware, making sense of all this real-time data and defining how much power can be driven down the line and into the load center. This is referred to as the dynamic line rating (DLR). For more details, see Transmission & Distribution World’s “Our Ubiquitous, Dynamic Grid” supplement, December 2013.

Timing Is Everything

Sacred cows die hard, especially when everyone is comfortable with the status quo and decidedly uncomfortable with some newfangled process. It is reminiscent of the time when the electronic calculator first came on the scene. Engineers would solve a problem with the electronic calculator and then check the answer with their slide rule. The slide rule is gone and so, too, will the obsolete piles of parchment currently used to set line ratings. DLR is here to stay and transmission owners will get used to it.

Several recent reports and studies have said DLR is the future of the transmission system and its components. The U.S. Department of Energy (DOE) published a report this year stating there is a huge untapped capacity available in existing transmission lines not being utilized. The report suggests it is possible to improve a transmission line’s rating by as much as 25%. This increase can be accomplished without changing structures or conductor sizes, or without increasing voltage levels, by using DLR technology.

The potential is huge and this unused capability is starting to get more interest as various groups see possibilities for this windfall. Several utilities have taken part in DOE pilot programs adding sensors and monitoring systems directly to their transmission towers and poles, turning them into the next generation of structures. Initial results are very promising, with preliminary indications showing the DOE’s report is correct in its assessment of underutilization. The utilities taking part in the experiment have reported increased capacities amounting to anywhere from 5% to 20% over their previous static ratings, so look for future structures to include smart technology as a standard feature.

Software Plus Hardware

Fabricators have developed some amazing materials and adapted them to their production procedures by integrating incredible control software to optimize the process. This trend is sweeping the manufacturing world. An article in Bloomberg Businessweek calls the matching of software and hardware “the next major technological change” opening a new dimension of advancements. So far, the process has resulted in producing advanced structural designs with greatly improved physical attributes, leading to some pretty futuristic tower and pole designs. Equally important to the user, this 21st century approach also has reduced production costs and shortened lead times, which are of major importance to utilities.

While this revolutionizing has been taking place in the factory, utilities have been busy with their own brand of merging form with function. Incorporating these advanced towers and poles into transmission lines requires a change in mindset for a lot of designers. That is where the adoption of sophisticated software design programs comes into play. It allows transmission engineers to reduce the number of structures per mile while producing stronger designs with storm-hardened attributes that could not be matched before this process was available.

Programs such as Bentley’s design software, ETAP’s transmission line software, Power Line Systems’ PLS-CADD and Southwire’s SAG10 are improving the transmission line engineer’s optimization techniques, but there is an attitude shift taking place at the same time. The old rules of thumb, popular as a designing shortcut, are no longer valid. They do not reflect the modern materials being used in today’s structures, which is why the complex design software is so important.

Back to the Nuts and Bolts

A good example of a futuristic structural material comes from the National Aeronautics and Space Administration (NASA). Usually, NASA does not come to mind when discussing transmission structures, but NASA teamed up with Brigham Young University (BYU) and has been doing some very promising R&D using carbon-fiberglass composites. NASA-BYU have joined these composites with something they call an IsoTruss grid (that is, 3-D lattice) structure for use in space, but the research is getting a lot of attention on earth. That is because it is extremely lightweight and as much as 12 times stronger than steel, depending on the application.

This grid design gets its name from the isosceles triangle and pyramid shapes used in the truss. NASA-BYU reports, “Any fiber and resin composite combination can be used to form the grid. It is the 3-D spiderweb-like structural design itself that makes the difference.” This physiology gives it the strength and eliminates the weight. The IsoTruss is less expensive to manufacture, transport and install than similar wood or steel structures. Like the composite structures currently in use, little to no maintenance is needed, it does not rust, corrode or rot, and insects do not like it.

Because of its lattice-like design, it has less wind resistance, which means it is less susceptible to storm damage when subjected to high winds. NASA-BYU estimates a 90-lb (41-kg) IsoTruss structure could replace a 1000-lb (454-kg) steel pole, which has gotten the attention of engineers in Japan and China. The scientists say these attributes make the IsoTruss design a good candidate for utility structures, but it will be several years before NASA-BYU applies this work to something like a transmission structure. They do point out the IsoTruss has been used for meteorological towers, so it should not be long until this new structure makes its way to the grid.

Tomorrow’s Tower

The electric grid is undergoing a lot of change and the only thing we know for certain is that it is not over yet. There have been a lot of roundtables, panel sessions and the like at conferences lately predicting where the industry will be going with the future power delivery system. Some have said overhead circuits have reached their zenith and will be declining; they will be replaced by underground circuits. A couple of futurists are saying the industry will go to a wireless system that does not use wire or cable. They cite recent developments in wireless charging systems for personal devices as proof of what is to come.

Whatever is coming, it will be interesting, and there will be challenges integrating it into the power network. More likely, the industry will achieve advancements in transmission and distribution structures, allowing them to be more visually pleasing along with added robustness. In Europe, architects and industrial designers are already joining transmission engineers to make transmission line structures more appealing aesthetically to reduce the negative visual impact. The future tower is going to be defined by the choices this industry makes, and it will be fun to see where it goes.