Benefits of Battery Monitoring Systems and NERC Definitions

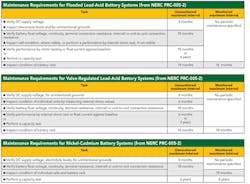

Stationary battery systems are among the most critical substation assets and are often the most overlooked. Recent changes to the North American Electric Reliability Corporation’s (NERC’s) Protection System Maintenance requirements, PRC-005-2 in particular, have placed new importance on these critical systems by including strict inspection, testing and maintenance requirements for bulk electric system (BES) battery systems. This document makes clear distinction between direct-current (DC) supply components that are continuously monitored and those that are not. Additionally, flooded lead-acid (FLA), valve-regulated lead-acid (VRLA) and nickel-cadmium (NiCd) batteries have different inspection, testing and maintenance requirements.

To comply with NERC’s requirements, utilities will need to make changes to maintenance practices that, likely, have been in place for many years. Battery monitoring systems enable the attention required for this asset, while greatly reducing resources that would otherwise be required, and can provide the necessary documentation to support NERC’s requirements.

Deserved Attention

Battery monitoring systems enable maintenance personnel to better determine the operating condition of DC supply systems, which are critical to the safe and reliable operation of the electric system. NERC and other regulatory agencies have placed strict operating and maintenance regulations on many critical electric system components, including battery systems. Failure to comply with these regulations could result in harsh monetary penalties. Battery systems have lived in the shadow of high-tech components such as protective relaying and,

often, have been overlooked as critical components. In reality, devices protecting the electric system cannot operate safely and reliably without a properly maintained and operational DC system.

Additionally, with reduced maintenance budgets, the loss of specialist crafts personnel and the reduction in maintenance staffing, regulatory compliance may be compromised without accurate data gathering, analysis and storage capabilities. Battery monitoring systems also enable users to obtain real-time information and act in a timely manner, should an issue arise.

NERC Definitions

To understand NERC’s requirements, certain required activities and definitions need to be understood first. The glossary of terms used in NERC reliability standards aids in understanding the meaning of particular activities.

These are some of the more important definitions:

- Protection system includes station DC supply associated with protective functions (including batteries, battery chargers and non-battery-based DC supply)

- Protection system maintenance program includes all batteries associated with the protection system; batteries must be included in a time-based program

- Verify that the component is functioning correctly

- Monitor routine in-service operation of the component

- Inspect for signs of component failure, reduced performance or degradation.

NERC Requirements

NERC PRC-005-2 differentiates maintenance requirements based on the type of battery in use. FLA, VRLA and NiCd installations have different requirements. Battery monitoring systems simplify compliance with all three of these battery types.

Battery monitoring systems can eliminate totally or reduce the number and frequency of required tasks, though visual inspections are still required for the batteries and racks, and NiCd batteries require a load test every six years.

NiCd batteries need to be considered differently from their lead-acid-based counterparts. Lead-acid and NiCd batteries use different technologies; their chemical and physical characteristics are not alike, resulting in dissimilar failure modes. While voltage can be accurately measured and tracked with battery monitors, ohmic measurements of NiCd batteries cannot be used to trend and predict failures. Typical failure modes of NiCd batteries include electrolyte starvation and hard shorts, which result in low cell voltage. NiCd batteries will measure as good until a failure of this type or until a severely discharged cell is identified. If properly set up when commissioned, battery monitors can detect these types of failure.

Collateral Benefits

In addition to reducing NERC maintenance requirements, battery monitors possess attributes that improve day-to-day maintenance activities. For example, battery monitors enable the user to receive real-time information regarding system float voltage, load current and battery room temperature. Monitors also allow verification of data obtained during ohmic tests performed by field crews; a questionable test value can be confirmed by querying the monitor.

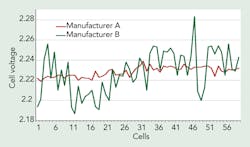

Another recently discovered return may be the evaluation of battery quality. Battery installations by two manufacturers were commissioned about three years ago. Both installations were valve lead-acid batteries of the pasted plate design. The primary difference was the battery capacity. Manufacturer A was 250 Ah while manufacturer B was 800 Ah.

Manufacturer A revealed very little voltage difference between the individual cells. It also clearly showed the difference in voltage caused by the variance in room temperature. Cells 1 through 30 were on the upper level of a two-tier rack while cells 31 through 60 were on the lower tier. Manufacturer B depicted a more substantial variance in the individual cell voltages, though all were within established tolerances. A statistical analysis revealed the standard deviation of the voltages for manufacturer B was 10 times that of manufacturer A. Similarly, the range for manufacturer B was five times greater than that of manufacturer A.

The difference between these installations brings up the question of the quality and consistency of the manufacturing process of manufacturer B. Further analysis is required before a definitive answer can be delivered.

But, can a battery monitor aid in determining the quality of a battery?

System Evaluation

Battery monitoring systems are produced by several manufacturers. IEEE standard 1491, IEEE Guide for Selection and Use of Battery Monitoring Equipment in Stationary Applications, is a valuable tool for understanding and specifying a system. In addition to this guide, end users must make decisions specific to their needs:

- Does the system have reporting capabilities?

- Can the reports be customized?

- Are there adequate alarm outputs available through dry contacts?

- Who will install the system?

- Who will monitor the system?

- How many utility installations have been completed?

- Does installation require the string to be removed from service?

- How easy or complicated is the software?

- How and where will the data be interrogated and stored?

- What communications protocols are available?

- What is the total installed cost?

The United Illuminating Co. (UI) has monitors from several manufacturers in use and has tried a variety of installation options. Rack mounting of the monitor is generally preferred; however, this is not always possible because of physical restrictions. Another option is wall mounting, either flat against the wall or on a mini-rack.

What’s Next?

At this time, UI has 13 monitoring systems installed, resulting in the monitoring of 22 strings. The initial intent is to complete installations at all BES stations by the end of 2013. After the BES stations are installed, other non-BES bulk stations will be prioritized for installations.

In concert with the installations, UI is exploring the means to interrogate the systems regularly, store the data, and set up alarming, monitoring and notifications to fully meet the NERC requirements of a monitored system.

Perspective

Battery monitoring is a viable solution for NERC compliance as an aid to reduce manpower requirements and to ensure these critical assets are properly assessed and operating in a safe and reliable manner. Many options exist for end users to create a system that best suits their specific requirements. Resources are available for this decision-making process, including utility users, manufacturer information, and standards for design, installation and implementation.

Anthony J. Picagli ([email protected]) is a principal electric system maintenance engineer at The United Illuminating Co., focusing on circuit breakers of all classes, gas-insulated substations and standby battery systems. He is active on several Doble Engineering client committees, chairman of the Doble Circuit Breaker Timing and Motion Committee, and vice chair of the Circuit Breaker Committee. He is a 35-year member of IEEE and a member of the IEEE Standards Association. He holds both a BSEE degree and a MBA degree from The University of New Haven and is a registered professional engineer in Connecticut.

Companies mentioned:

North American Electric Reliability Corp.| www.nerc.com

United Illuminating Co.| www.uinet.com