HVDC Advances in the Russian Federation

The Russian Federation, the largest republic of the former Soviet Union, has been an independent state since 1991. The All-Union Power Pool System of the European part of the former Union of Soviet Socialist Republics remained in Russia as part of the United Power System (UPS) of the Commonwealth of Independent States. With Russia’s power sources located mostly in the east and load centers in the west, the main transmission lines have been built from east to west.

All of Russia’s other high-voltage direct-current (HVDC) systems and back-to-back (BTB) HVDC links have been planned, commissioned and operated by the country’s Ministry for Electrical Power and Electrification. With the exception of the first HVDC project between Kashira and Moscow, which was the only one constructed using foreign equipment, the HVDC projects have been constructed using major plant, automation and protection equipment developed, manufactured and delivered by the factories of the Ministry for Electrotechnical Industry.

The former Soviet Union started HVDC system research and development (R&D) at several scientific research institutes in the 1930s, but the first project was not commissioned until 1950. Three organizations from the former Soviet Union played the main part in the implementation of all of the HVDC systems:

- Energosetproject, the leading project organization

- All-Russian Electrotechnical Institute (VEI), developer of the HVDC equipment

- Direct Current Power Institute (NIIPT), developer of the specifications.

More than 60 other R&D institutes, project and construction organizations, and industrial enterprises took part in the creation of HVDC systems. The following is a summary of major Russian HVDC systems.

Kashira–Moscow HVDC Link

Commissioned in 1950, the Kashira–Moscow project was the first HVDC system in the world. It is a two-pole system that is comprised of a 120-km (75-mile) ±100-kV underground cable circuit, with a load-transfer capacity of 30 MW. The system was built using equipment designed and manufactured by German companies Siemens and AEG for the Elbe–Berlin project, which was never put into service by Germany. By 1953, the underground cable was replaced with cable manufactured at the Soviet plant Moscabel.

This HVDC system — using coke-filled ground electrodes, lightning arresters, mercury-arc valves, and control and protection systems — was the result of a five-year R&D program on all equipment undertaken by VEI and NIIPT.

Volgograd–Donbass HVDC System

The Volgograd–Donbass system is a two-pole, ±400-kV overhead line that stretches 473 km (294 miles) between two 220-kV ac systems. The aluminum-steel 600-mm2 (0.93-in2) conductors have a load-transfer capacity of 720 MW.

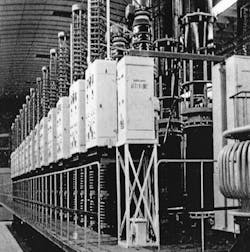

The converter stations are similarly equipped with eight six-pulse valve groups, with each valve group originally having 14 mercury-arc valves; at the Volzhskaya HVDC substation, the mercury-arc valves have since been replaced with high-voltage thyristor valve groups, developed by VEI. Construction started in 1962, with commissioning in 1965. For many years, this was the largest HVDC scheme in operation in the world.

Ekibastuz–Center HVDC Project

Ekibastuz–Center was a major project for which planning commenced in 1970 by the Energosetproject, VEI and NIIPT. The objective was to provide an interconnection to supply 6,000 MW from the Ekibastuv Thermal Power Plant in Kazakhstan to offset a power deficiency in the center of Russia. The planned HVDC interconnection included a 2,400-km (1,491-mile) HVDC bipolar transmission line operating at ±750 kV with a line rating of 4,000 A, or a load-transfer capacity of 6,000 MW.

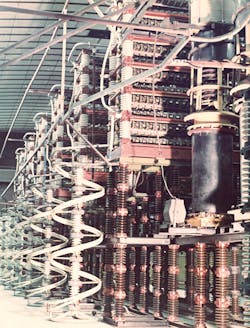

Each pole consisted of two branches connected in parallel with each branch having a high-voltage, water-cooled 12-pulse thyristor valve group. For the first stage of the Ekibastuz–Center HVDC project (1,500 MW), the following major plant items were manufactured:

- HVDC thyristor valves BVPM-800/470-III

- Single-phase, two-winding converter transformers rated at 320 MVA for dc voltages of ±400 kV and ±750 kV

- Line reactors rated at 4 H, 1,000 A for a dc voltage of

- ±750 kV

- Lightning arresters RL, RG-400 and RG-800

- Control, protection and automation equipment.

During the period between planning and execution of this project, a large test station was established in the city of Tolgliatti in 1979. This was the first high-voltage test station in the world designed for full-scale, long-term testing of all the equipment required for high-voltage alternating-current (HVAC) systems up to 1,150 kV and HVDC systems up to 1,500 kV. These voltage levels are higher than those currently being used in similar test facilities established around the world.

Following completion of the test program, equipment was delivered to the Ekibastuz and Tambov converter stations for the first 1,500-MW stage and then construction began. About 1,000 km (621 miles) of the ±750-kV HVDC overhead line was completed before the collapse of the Soviet Union, which stopped all site and line construction works. Equipment delivery started in 1989 and then stopped in 1991, with the line then dismantled, never having been commissioned. It is now apparent that, at the time of the development of the ultra-HVDC system, Russia was some 20 years ahead of the rest of the world.

Vyborg BTB HVDC Link

The Vyborg BTB link connects the 330-kV HVAC system in northwest Russia to Finland’s 400-kV HVAC system. The majority of this project was commissioned during 1981 to 1984, with the construction of three high-voltage converter units (HVCUs), each rated at 355 MW, or 1,065 MW in total.

The power-transfer capacity was for 600 MW, but this was increased after the first year as the energy transmitted (4,500 GWh) exceeded the contracted total (4,000 GWh). After the trial operation period, which was less than one year, the mean annual energy transmitted through the link was about 4,500 GWh.

At the end of the 1980s, reconstruction of the Vyborg BTB started, following the deferment of the Ekibastuz–Center HVDC project. The high-voltage thyristor valves were replaced, and the new technologies originally developed for the Ekibastuz–Center HVDC project were used. Further refurbishment and expansion work resumed at the Vyborg BTB in the mid-1990s. In 2000, the fourth high-voltage converter unit (HVCU-4) was commissioned, and the transfer capacity of the link was increased to 1,420 MW.

A second stage of upgrading took place from 2002 to 2005 with the installation of new control, protection and automation on the first three converter units that included a microprocessor for active and reactive power control.

Finally, in 2010, all the control, protection and automation software was modernized, including the provision of a control loop for the new 50-MVA static synchronous compensator (STATCOM) installed at the BTB. The STATCOM was developed at the Scientific and Technical Center of Power Engineering Industry of the JSC Federal Grid Co. United Power System in Moscow. As a result of the reconstruction, energy transmission through the BTB was increased from 4,500 GWh in 1999 to 10,600 GWh in 2003.

Modern HVDC Developments in Russia

Since 1991, only two HVDC links in Russia have been in operation, namely the Volgograd–Donbass link and the Russia–Finland Vyborg BTB, with no immediate plans in place for further HVDC system development.

In 2007-2008, VEI together with the OAO Electrovypryamitel, in the city of Saransk, provided the R&D resources to develop the serial production of a unified converter module equipped with optic-electronic control, a 12-kV dc voltage level and a dc current rating of 2.5 kA. The development of this module is just one of the latest innovative achievements that will be incorporated in future high-voltage power converters for use in new HVDC systems, BTB projects and static volt-ampere reactive compensators.

In 2008, the Russian Federation approved a general scheme for the allocation of Russian Federation Power System objects by 2020 (General Scheme 2020) with regard to the following:

- Thermal and nuclear power plants with capacity 500 MW and above

- Hydro power plants with capacity 300 MW and above

- Substations, transmission lines 300 kV and higher providing power-delivery systems from power plants, and intersystem transmission lines operated by the UPS of Russia to be constructed between 2010 to 2020.

According to that General Scheme, the construction of 8,150-MW Evenkiiskaya HPS at the Nizhnyaya Tunguska River in northeast Siberia was stipulated and two HVDC transmission lines ±500 kV, 2,500 MW Evenkiiskaya HPS–Tyumen 600 km and 800 km (373 miles and 497 miles) were proposed.

HVDC lines ±750 kV, 3,000 MW Siberia (Itat)–the Urals–Centre (Tambov) 3,700 km (2,299 miles) and the Urals (Ekaterinburg)–Centre 1,850 km (1,150 miles) also were planned to provide power to the European part of Russia. In addition, three HVDC power transmission lines ±750 kV (or ±600 kV), 3,000 MW from Siberia to the state border with China were considered to ensure the export of power to China.

The extension and reconstruction of the Vyborg HVDC BTB station was considered as well as the construction of new HVDC BTB stations 200-MW Mogocha and Khani in the far-east, 500-MW Knyazhegubskaya BTB to increase power export to Finland and 500-MW Tsentralnaya BTB for power export to Poland.

In 2010, the General Scheme 2020 construction program was reviewed and, as a result, the decision was made to correct the forecast development by taking into consideration factors that included a reduction in power demand because of the increase in economic efficiency.

A 200-MW BTB is under construction at the Mogocha substation in the Chitinskaya Power System in Siberia. It is now at the delivery and assembly stage in which equipment developed and manufactured in Russia is being installed. This BTB is located between the two separate and unconnected 220-kV transmission systems in the east (Chita) and far-east (Khabarovsk) of Siberia. The project consists of two parallel circuits, each capable of transmitting 100 MW in either direction. A total of four voltage source converters are connected by a three-level circuit with an installed power of 102 MW. The commissioning of the Mogocha BTB is expected in 2014.

The construction of the similar 200-MW BTB station Khani, connecting 220-kV systems between Irkutsk and Khabarovsk, is planned for 2014.

The decision has been made to construct a ±300-kV HVDC system, which will have the capability to output 1,000 MW, between the Leningradskaya nuclear power station and Vyborg BTB. This link will involve the construction of both an undersea cable and an overhead bipolar transmission circuit. This could result in the possibility of increasing the power capability of the Vyborg BTB. Alstom is expected to supply and deliver the equipment for this project, which is due to begin in 2014.

The construction of Kaliningradskaya nuclear power station is planned with a scheduled output of 1,000 MW in 2017 and an additional 1,000 MW in 2020, with the majority of the output to be available for export. A 330-kV HVAC transmission line to Lithuania is planned, together with the construction of two BTB substations, at Mamonovo, each rated at between 500 MW and 600 MW. One BTB will be interconnected to the Polish transmission system and the second BTB may be interconnected to the transmission system in Germany.

Lev V. Travin ([email protected]) received BSEE and MSEE degrees in power stations, electrical systems and grids from the Moscow Power Engineering Institute before joining the All-Union (now All-Russian) Electrotechnical R&D Institute in 1956. He has more than 50 years of experience in research, development and R&D planning of HVDC power transmission. Travin has been member of the International Electrotechnical Commission since 1964 and was the secretary of IEC Technical Subcommittee 22F, Power Electronics for Electrical Transmission and Distribution Systems, in 1990. In 2011, the IEC awarded him the Thomas A. Edison Award for exceptional achievement in committee management. Travin is also an individual CIGRÉ member.

Dr. Vladimir V. Khudyakov ([email protected]) earned his MSEE degree in electrical power plants, power networks and systems in 1950 and his Ph. D. in electrical power systems in 1954, both from the Moscow Power Engineering Institute. Khudyakov worked at the All-Russian Electrotechnical Institute (VEI) from 1953 to 1998. His responsibilities included high-voltage power systems, all the Russian HVDC systems, back-to-back HVDC link equipment design, testing, delivery, adjustments, commissioning and operations. Khudyakov was awarded the title of Distinguished CIGRÉ member in 1998. He is a senior member of the IEEE and, following his retirement, he is now working as an independent consulting engineer.

Companies mentioned:

Alstom | www.alstom.com/uk

DC Research Institute (NIIPT) | www.niipt.com

Energosetproject | www.oaoesp.ru

JSC Electrovypryamitel | www.elvpr.ru

Ministry of Energy the Russian Federation | minenergo.gov.ru

Moscabel | www.moscabelmet.ru

Siemens | www.siemens.com

Scientific and Technical Center of Power Engineering Industry of the JSC Federal Grid Co. United Power System | www.ntc-power.ru

VEI | www.vei.ru