Uncertainty is the enemy of a utility. Accordingly, processes and procedures have been set up to manage or mitigate risk for many of the electromechanical devices that make up and control the power grid. But what can a utility do when something unexpected happens, resulting in a forced outage? How can a utility determine if a critical asset is fit to be returned to service? Sweep frequency response analysis (SFRA) can serve as a key indicator of whether a transformer can be re-energized or if there is a need to work out an alternative.

SFRA interpretation looks complicated at first, but the technique is simpler than it appears. A trace represents the fingerprint of a given winding; changes to that fingerprint mean something has changed from one measurement to the next. Sometimes this can be a dangerous mechanical change, like a winding being damaged, and sometimes it represents a natural process, like a byproduct of fluid movement inside the tank or a change in the grounding circuit. When SFRA traces are compared, one wants to consider both the traces themselves, how the traces might have changed over time and, most importantly, the context surrounding the measurement to determine what the next steps might be.

SFRA at Lower Colorado River Authority

Lower Colorado River Authority (LCRA) was one of Doble's first partners to apply SFRA as a testing technique. LCRA began using SFRA in 2002 to assess the condition of its transformer fleet. Technicians performing the tests were able to quickly develop skills in field analysis because of the graphical nature of results, allowing for quick adoption of the tool as a part of routine field testing. In particular, after a significant fault event, LCRA viewed SFRA as a way to provide a more detailed analysis of physical changes to the core and coil assembly of a transformer than traditional methods of testing. When a transformer is off-line, many are counting on the utility to return it to service as soon as possible. The ability to quickly analyze results and compare them to baseline values provided LCRA with the means to make timely determinations about re-energizing transformers.

LCRA has integrated SFRA into three of its tests:

-

Validation of factory tests during on-site acceptance testing

-

Production of baseline data sets, after the assembly and processing of a new transformer

-

Routine maintenance testing and comparison to baseline data established during acceptance testing.

SFRA also is used after abnormal operations and occurrences. After a tripping operation, it's important to exercise caution to limit the voltage levels applied as a result of the presence of combustible gases within a transformer tank. Because SFRA uses low voltages, LCRA uses it to perform initial troubleshooting after an event.

Any significant deviations are taken to indicate physical changes that may require further investigation. SFRA provides quick analysis, therefore, it has become essential to LCRA's ability to make timely determinations about re-energizing transformers.

Relocation Case

Because of the redesign of a 345-kV substation, LCRA had to move a 345/138-kV, 480-MVA autotransformer approximately 100 yards (91 m). The unit serves as a system spare and was relocated to make room for the arrival of a new transformer within the substation. Given the small distance involved, LCRA decided the unit could be moved in field service condition to minimize downtime associated with a teardown and rebuild of the unit. The move employed a jack and slide method to place the unit on a trailer and unload it to the new base; no unexpected events were noticed or tracked on the impact recorder.

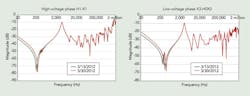

To identify any possible mechanical change, SFRA was done both prior to and immediately after the move. The comparison of the before traces with the after had an anomaly that required further review.

Magnetic viscosity represents a change in the various magnetic domains that exist in core laminations: as temperatures change, or even as a unit sits undisturbed, the Brownian motion of the fluid insulation and its resultant collisions with the transformer core can alter the magnetic energy stored in the core steel. This effect is primarily confined to the lowest frequency area of an SFRA trace. If there were truly a mechanical change or shifting of the core, this would affect the capacitive coupling surrounding the core and, hence, impact the trace at higher frequencies. However, none of this is present.

One of the confirmations of magnetic viscosity effects is its impact on all windings. This is found in the response of the common winding of the same phase. As a result of the analysis, in combination with no other measurements indicating a problem in this context, the transformer was deemed fit for service. The transformer was subsequently called into service at another substation and has been energized for approximately one year with no issues.

Line-to-Ground Fault Case

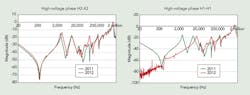

In 2012, a two-year-old 345/138-kV, 672-MVA autotransformer saw a line-to-ground fault on the C phase, which caused the unit to trip off-line because of a differential relay operation. During the post-fault investigation, it was determined a pressure relay also tripped. Fault analysis revealed the event was likely isolated to the transformer as no system events could be correlated to the operation. There was suspicion an internal failure had occurred. SFRA was performed and a comparison was made to traces provided by the manufacturer at a similar tap position.

A shift is observed at the lowest frequency when comparing the baseline to the most recent open circuit measurement in one phase. However, a new resonance appeared at around 550 Hz. There were additional variations higher in frequency — both in the low-kilohertz range, which corresponds to bulk winding movement, and in the mid-kilohertz range, which corresponds to interwinding issues. By itself, the comparison of just this phase to the benchmark tends to indicate a winding fault.

The indicators of a physical shift are even stronger in the traces seen in a separate phase test, along with the aforementioned bulk winding and interwinding issues; the area associated with the core response demonstrated a significant drop-off in the lowest frequencies. This kind of response is sometimes associated with an open winding circuit. In any case, the drastic change in the trace could not be written off as a simple magnetic issue.

Because of the extreme variances in the SFRA measurements performed, an internal on-site investigation was warranted to provide an assessment of damages. This inspection revealed a failure of the de-energized tap-changer mechanism, which resulted in significant physical damage and, in effect, caused an open high-voltage winding circuit.

Testing Transformer Internals

SFRA provides a unique diagnostic tool that allows LCRA to make informed decisions about its transformers and the utility's test technicians to quickly analyze results during critical outages. Integration of the technique in all phases of transformer testing (acceptance, routine and trouble) has allowed LCRA to monitor units for significant physical changes that affect operating integrity and characteristics.

SFRA has proven to be a valuable testing tool that can differentiate between traces indicating genuine condition problems and traces indicating benign behaviors. Health analysis of transformers using SFRA allows LCRA to continue its mission of providing reliable electric transmission services.

Dan Perry ([email protected]) is a supervisor of system protection and control at Lower Colorado River Authority in Austin, Texas, U.S. He has more than nine years of experience in the application of diagnostic testing of substation equipment, having served as a test technician with LCRA and in a previous capacity with a transformer manufacturer. He is currently completing studies for a bachelor's degree in computer science.

Matt Garber ([email protected]) is a client service engineer with Doble Engineering. He has worked in the utility industry for five years, in system planning and operations and maintenance. He has bachelor's degrees in electrical engineering and anthropology from the University of Massachusetts at Amherst.

Sidebar: Sweep Frequency Response Analysis

In the field of transformer diagnostics, sweep frequency response analysis (SFRA) is a measurement that gives the user information about the internal condition of apparatus. SFRA measurements usually are performed between two terminals on a winding at several different frequencies. Frequencies typically start anywhere from 1 MHz to 10 MHz and go down to 10 kHz to 20 Hz, and the ratio of output-to-input voltages at each step is recorded and calculated.

As a result, the frequency response built up over the entire tested range is often likened to a fingerprint: it uniquely describes the electrical characteristics of the device. When reviewing SFRA data, a user looks for the frequency at which resonances (and anti-resonances, though the former term is often used for both) are located.

Resembling a peak or valley, a resonance in a SFRA trace represents the transition from a dominant effect of one reactive element in a circuit to the other. Capacitances and inductances respond differently to ac signals, because a series capacitor blocks low frequencies and passes high frequencies; an inductance does the opposite. Once a response has been defined, any variation reflects a change in the physical makeup of the asset — in most cases, representing a physical shift, though it also can be a result of some known natural phenomena.

SFRA analysis is most useful when a fingerprint has already been established, but a comparison to a sister unit typically can yield results of nearly equal value, and some information can be gleaned by an experienced analyst from a phase-to-phase comparison.

Any complex system has its challenges; however, in the case of SFRA, these can be overcome with familiarity and exposure to the analysis of the data. One phenomenon, in particular, that has a known cause and a set explanation, causes a large number of false positives for mechanical alteration to an asset. It is called magnetic viscosity and is caused by interactions between a transformer core, and the thermal fluid bath of the oil it sits in. It can be established whether magnetic viscosity is a concern by looking at the context surrounding a measurement; this context, combined with some understanding of the physics behind the measurement, helps determine what is critical and what is not.

LCRA | www.lcra.org