EDP Distribuição is implementing an asset management system to consolidate asset management policies and further disseminate asset risk management practices. As a result of new challenges arising from the implementation of this asset management system in terms of performance, cost and risk, EDP Distribuição had to change the paradigm of maintenance previously adopted.

As the main electricity distribution system operator in Portugal, EDP Distribuição supplies more than 6 million customers through 400 high-/medium-voltage (HV/MV) substations and 65,000 medium-/low-voltage (MV/LV) substations over a network that includes 80,000 km (49,712 miles) of HV and MV networks and 140,000 km (86,996 miles) of LV network.

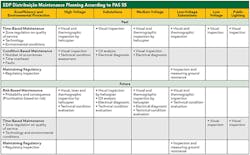

EDP Distribuição developed a maintenance program using time-based, condition-based and regulatory-based maintenance. Each asset had a specified maintenance activity based on visual inspections and electrical tests performed monthly or in five-year periods, depending on the asset’s risk profile.

Data from the maintenance activities is distributed to the utility’s various systems, enabling the utility to manage its assets by establishing short- and medium-term maintenance plans. However, because of the lack of information on each asset’s operational history, a comprehensive view of the health index of each asset was not available. Therefore, EDP Distribuição is implementing an asset management system compliant with PAS 55, the publicly available specification published by the British Standards Institution (BSI).

Predictive maintenance will result in the utility taking action before failure, thus reducing outages, improving service quality and reducing costs. EDP Distribuição is testing and implementing solutions to perform on-line monitoring on a wide variable set among scattered physical assets, which will pave the way for a holistic view of each asset.

Framework

The energy sector in Portugal is privatized and deregulated, in parallel with other market-oriented reforms. Given this environment, rationality and transparency are key to building shareholder trust and attracting other investors. Asset management is essential to the performance and growth of electrical utilities. Effective asset management takes into account capital and operating costs, customers and the environment. It also ensures risks are managed and levels of investment are appropriately targeted.

Distribution system operators manage many assets daily. But financial constraints may reduce asset investment. Thus, a detailed risk assessment methodology is needed to delay asset replacement, thereby improving asset payback.

Collaborating with the Institute of Asset Management, BSI PAS 55 was designed to specify good practices in physical asset management. It focuses on physical assets and advocates asset life-cycle analysis to optimize all expenditures associated with the asset, including creation and acquisition, usage, maintenance, renewal and disposal. It is divided into four phases:

• Plan. Define a strategy, objectives and plans for the project that align with the policy and utility strategic plan.

• Do. Implement the plans in the field, following the specifications and requirements.

• Check. Detect errors or anomalies through monitoring and measurement of the work processes.

• Act. Correct errors detected in the “check” phase.

With this four-phase cycle, it is possible to check all processes in a continuous way. Integrated into the smart grid concept with respect to real-time asset monitoring, EDP Distribuição is currently running three projects.

Active Transformer Breathers

The HV/MV transformers have the oil at atmospheric pressure by means of a breather pipe that allows air circulation between the tank and external environment. To reduce the moisture content of air traveling to and from the transformer, the breather pipes are equipped with an air dryer in series with the air circuit.

A dryer typically consists of a container filled with silica gel through which the incoming or outgoing air from the transformer has to pass. The silica gel changes color according to the accumulated moisture content, providing an easy indicator of the status to maintenance teams. Once the silica gel is saturated, it is replaced and properly managed as industrial waste. On average, EDP Distribuição has to replace the silica gel in each transformer every three months.

Currently, EDP Distribuição has a pilot project to test a new type of air dryer with special silica that can be regenerated, or dried, resulting in an average lifetime of 10 years. This air dryer is equipped with sensors that measure the temperature and moisture content of the air. When these parameters exceed predetermined values (indicating the silica is saturated), they activate a heater that dries the silica. The device has data storage and communications capabilities that allow it to register status operating information and assess the silica condition to detect whenever it needs to be replaced.

This project is in use at four HV/MV substations, each equipped with two transformers located in areas typically associated with high levels of air moisture. In each substation, one transformer is equipped with the new air dryer while the second transformer has the conventional dryer, allowing EDP Distribuição to compare the two dryer technologies in terms of effectiveness and maintenance costs.

The effectiveness assessment relies on periodic oil analyses that help to compare the evolution of moisture in oil for the different dryer technologies. These analyses are compared with the transformer load diagrams to determine the effect of load imbalances, which can affect the transformer breathing rhythms and mask the effectiveness of the dryer. From the data recorded to date, the new dryer is seemingly as effective as the conventional dryer, but the main benefit has been the reduction of maintenance costs associated with silica replacement.

Primary Substation Monitoring

Automation and asset management of the 400-HV/MV primary substations supplying the distribution network is critical for the continuity and quality of service. EDP Distribuição has a pilot project with a national consortium — Eneida Wireless and Sensors and the Faculty of Sciences and Technology at the University of Coimbra — that comprises a network of innovative and pioneering sensors monitoring critical parameters on circuit breakers, switchgear and transformers installed in primary substations. The circuit breaker monitoring focuses on the collection of transient electrical current data during switching and vibration data. This provides a pattern signature for each device, and early signs of mechanical malfunction can be detected through comparative analysis with the real-time data available from the previously recorded signature.

The sensors installed at the switchgear are monitoring moving-part contact wear and temperatures. Vibration and temperature data is also collected on the HV/MV transformers to provide a performance signature for comparison with future data. This will result in early warning of potential malfunctions. Since batteries were to be avoided, powering smart sensors in the primary substation switchyards presented a challenge. Thus, the smart sensors in circuit breakers and on HV disconnect switches are powered by energy-harvesting and storage devices charged by small 8-cm × 8-cm (3.15-inch × 3.15-inch) solar cells.

Currently, the application software at the coordinator center supports the two required approaches to asset information:

• A supervisory control and data acquisition system, promptly presenting all the relevant information in graphic formats and providing a set of tools for a long-term, strategic asset management

• An alarm-issuing station serving the short-term maintenance needs, thus remotely transmitting warning and alarm messages in line with the level of urgency in the required response procedures, as defined by the health assessment criteria adopted for the different substation equipment. The ultimate goal from this database should include automatic generation of worksheets issued electronically to maintenance teams in the field.

The recorded data from equipment being monitored was initially used to determine some common patterns described as standard behavior under normal working conditions that could then be applied as criteria applicable to all equipment sharing the same brand, type, production series, age and length of time of service. This proved to be unsuccessful, so the class of equipment idea was abandoned and such references were adopted on an individual basis.

The criterion recently adopted for the health assessment of the electromechanical equipment in a substation corresponds to a real-time average calculation of the relevant variables’ values with an offset based on standard deviation.

Given the low number of events recorded at the substations under observation, namely, circuit breaker operations, the respective reference figures still lack statistical significance and, therefore, no message warnings and alarms have been set for this equipment.

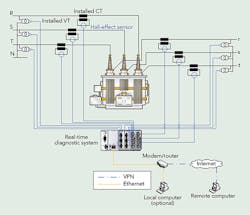

EDP Distribuição is also collaborating with the University of Coimbra to develop a real-time diagnostic system for power transformers. The system measures the primary and secondary currents and voltages of the monitored transformer to detect incipient faults occurring in windings or in the core, through Park vector analysis in addition to the degradation of the contact resistance of the transformer on-load tap-changer. This technology has been successfully applied to industry for diagnosing faults in motors and variable-speed drivers for the last 20 years and is now being adapted to static machines like power transformers. Currently, EDP Distribuição has an experimental version of this system running as a pilot in two primary substations.

Secondary Substation Monitoring

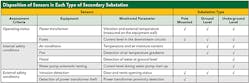

EDP Distribuição operates more than 65,000 MV/LV secondary substations equipped with one or more transformers that have voltage levels ranging from 10 kV to 6 kV and a significant percentage have been in service for more than 30 years. Depending on the installed transformer capacity and the type of network, transformers can be pole mounted with rated capacities to 250 kVA on rural overhead line networks or located in buildings at ground or underground level with transformer ratings above 250 kVA. These substations are spread across inland Portugal and have more vulnerable equipment than substations with transformer failures for the period 2009 to 2011 exceeding 20,000 per annum.

Through the InovGrid project, the consortium together with Efacec partnered on a pilot that comprises a network of sensors to monitor critical parameters of secondary substation assets, namely the MV/LV transformer — the most critical asset in such installations. As an example, to combat both the rapid equipment decay and the recent wave of copper thefts, remote condition monitoring offers a key solution. This includes providing real-time monitoring, assessment and remote communication of several status conditions in secondary distribution substations.

The EDP Distribuição project consists of monitoring the operational condition of breaking and switching equipment, the transformer as well as environmental parameters inside the secondary substation, such as air temperature and humidity measurements, fire and flood detection, access control and transformer theft detection.

Monitoring of the transformer includes vibration and temperature measurements taken by noninvasive sensors that can be applied to the installed transformer. This data is remotely collated and stored by an application that automatically generates an alarm every time the real-time measurements deviate from a previously established pattern.

This project was successfully incorporated in the communications architecture developed for EDP Distribuição’s smart grid initiative. The distribution transformer controller, the InovGrid project’s device installed in a secondary substation, collects data coming from the consumers and transmits it upward to BTGrid, InovGrid’s remote platform, which acts as a gateway for the data coming from the sensors.

Capitalizing on Progress

The evolution of the smart grid has been driven by the twin objectives of energy efficiency and operational flexibility, by pursuing the ability to manage energy flow across networks with smart metering as well as several automation mechanisms and tools. In this process of distributing intelligence throughout the infrastructure, the logical counterpoint to such operational goals is in the ability to manage the relevant capabilities of scattered physical assets, with criteria and tools of the asset management scope, from investment decision support and, thereafter, throughout the entire asset life cycle.

Recent significant advances in different technological areas — sensors, microsystems, wireless networks and web service programming — have made it feasible to bring industrial maintenance to higher levels by bringing together maintenance, operation and engineering through the whole life cycle of assets. The key to this policy lies in the ability to monitor, in real time, several variables that describe the operating status and condition of equipment that, being critical to the respective process operation, should be subject to more sophisticated maintenance criteria: condition-based maintenance and, in the long term, other forms of predictive maintenance based on risk management criteria, as preferred by most utilities.

Aligned with this challenge, EDP Distribuição is developing different pilot projects to test new real-time sensor solutions by specifying and demonstrating innovative smart sensors for real-time monitoring of several new variables on critical assets in primary and secondary substations. Capabilities that enable gathering, analyzing and supporting human decisions — while they do not start sending out worksheets — represent a valuable tool for high-level asset management, increasing the amount of intelligence dispersed throughout the electrical grid. These solutions deserve to be designated as smart.

Finally, closing the gap between the birth of this idea and the manufacturing of the end product was accomplished successfully as a result of fruitful cooperation between the industry, the manufacturer and academia.

Pedro Carreira ([email protected]) is an electrotechnical engineer in telecommunications. He joined EDP Distribuição in 2001 as telecommunication investment and project manager. Since 2013, Carreira has been leading the innovation and development department, which acts as an enabler of new technologies, developing and testing innovative solutions as well as pioneering more efficient technologies.

Jorge Manuel Gomes ([email protected]) is an electrotechnical engineer specializing in electrical power systems and also has a MBA degree. He joined EDP Distribuição in 1995 and progressed through areas that included projects, dispatch and control of the electricity grid, and maintenance and asset management. Gomes is currently responsible for the planning and control department.

Rui Bernardo ([email protected]) holds an degree in electrical engineering from the Instituto Superior Técnico and has been working in the innovation and development department at EDP Distribuição since 2008. He has participated in the development of innovative projects for the utility on the transcription of protection and automation specifications to IEC 61850, dynamic ratings of overhead lines, power factor correction and new solutions for rights-of-way inspections.

Hugo Ferreira ([email protected]) is an electrotechnical engineer who specializes in risk assessment, safety and reliability. He joined EDP Distribuição in 2004, starting in the maintenance department, where his current activities include asset management of high-/medium-voltage networks, technical asset condition assessment and service provider contract management.

Mentioned in this article:

EDP Distribuição | www.edpdistribuicao.pt

Efacec | www.efacec.com

Eneida | www.eneidaws.com

Inovgrid | www.inovgrid.pt

University of Coimbra | www.uc.pt/en/fctuc