Tennessee Valley Authority (TVA) is a strong advocate of finding new and innovative ways to modernize the grid. Through the Smart Wire Focused Initiative (SWFI), sponsored by the National Electric Energy Testing, Research and Applications Center (NEETRAC), TVA has teamed up with the U.S. Department of Energy's (DOE's) Advanced Research Projects Agency-Electric (ARPA-E) and Smart Wire Grid Inc. (SWG) to deploy an array of distributed series reactance (DSR) units. The system is designed to provide congestion relief by redistributing power flow, thereby improving transmission system operations. The goal of this test bed is to prove this new technology can address flow-control issues in a cost-effective manner and be deployed with little, if any, outage time.

The hardware consists of an array of DSRs that easily clamp onto a transmission conductor. TVA has installed 99 DSRs (33 per phase, covering 17 tower spans) on a 161-kV transmission line near Knoxville, Tennessee, U.S. The DSRs allow operators to manage the current flow on the line by injecting inductive reactance on command, and they can be programmed to operate autonomously or with full operator control and provide distributed line sensing and monitoring. The distribution of the devices allows operators to vary the line impedance according to system needs. By using large numbers of low-cost, mass-produced devices, each array becomes immune to individual device failures.

TVA is leading a demonstration, supported by funding from NEETRAC's SWFI members — TVA, Southern Company, Baltimore Gas & Electric and the National Rural Electric Cooperative Association — the DOE's ARPA-E and the utility's own energy delivery organization. This project represents a milestone in moving the smart wire technology from concept to development and into utility operations. The concept was created in 2005 by Dr. Deepak Divan, who is now at Georgia Tech. In 2006, the California Energy Commission provided basic lab development funding to Georgia Tech. Smart Wire was identified as a key enabling smart-grid-control technology in the DOE's Modern Grid Initiative 2007 report.

TVA saw the potential for this technology and became an early supporter of the concept. From the initial unveiling of the concept some years ago, TVA has continued to support the technology development effort through NEETRAC and project-specific funding of SWFI. SWG licensed the technology from Georgia Tech Research Corp. in 2011.

Utility Industry Benefits

The DSR test bed provided a unique opportunity for TVA, as well as the utility industry, to become integrated into the product development process. Working directly with the manufacturer allowed for advancements that directly address the market's needs.

Regular meetings with NEETRAC SWFI members fostered an open dialog and facilitated information flow to support product development, testing and enhancements. The manufacturer supported utility input, through SWFI members, bringing multiple utility influences to bear. NEETRAC's experience has demonstrated that delivering a utility-friendly product to market is much more achievable when end users provide input early in the process and have an oversight role in product development and testing. This approach has created a win-win opportunity.

The SWFI utilities set aggressive performance targets for the DSRs, including low losses, high levels of fault withstand and quick installation times. With input and support from the SWFI member field crews, SWG designed an installation tool that enables DSRs to be installed very easily. The installations on the TVA pilot line averaged less than 15 minutes per unit, round-trip, including wire brushing of the conductor and installation of protector rods, the DSR and a vibration damper. Crews installed 99 DSRs in half the time expected.

System Impacts

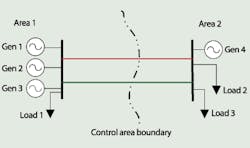

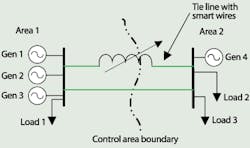

Deploying one DSR per mile per phase can allow operators to increase the line impedance by approximately 2%. The line impedance increase reduces power flow through the line, shifting flow onto other lines with available capacity in the grid. The preliminary results from TVA and SWG's load-flow analysis demonstrate the concept application in meshed networks.

DSRs are self-powered, using line current, and require no more field work than installing them on the targeted lines. The technology is capable of deployment using two-way communications with the installing utility, thus allowing control and contingency support.

Grid Benefits

Transmission systems are being reconfigured to accommodate the shifting generation landscape. Globally, utilities are seeing a larger range of generation sources and, in many regions, there is a significant redeployment of generation fleets either planned or underway. The magnitude of the problem is significant and expected to grow over the next decade as the generation mix is fundamentally reformulated.

Traditionally, utilities were limited to more expensive methods to address overloaded lines and system capacity constraints. The key to solving transmission system loading constraints in the most cost-effective and coordinated manner is a thorough systems engineering analysis. The final selection of the specific solution technologies is based on a combination of engineering and economic analysis. The choice is a function of the objectives to be achieved, the performance of each solution in attaining the performance specifications and the total costs involved.

TVA expects that DSRs will exhibit many attributes:

-

Low engineering costs

-

Low equipment costs

-

Flexibility — Able to be installed or redeployed quickly to address shifting requirements

-

Low site costs — Installed on existing transmission lines, no substation engineering or additional substation space requirements

-

Low balance of plant costs

-

Fast installation, testing and commissioning

-

Low ongoing operations and maintenance costs

-

Easy integration into utility operations, including training.

DSR installations can be engineered, specified and deployed in a matter of weeks. They offer effective power-flow control for the grid and are a cost-effective, simple and reliable alternative to conventional technologies and flexible ac transmission system devices.

Communications

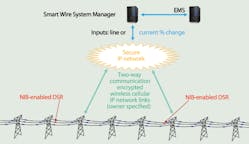

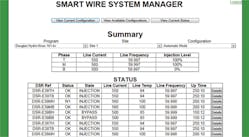

DSR deployment converts the existing transmission system to a smart asset that can bring extensive monitoring capability, regulate power flow and effectively shift overloads to underused portions of the network. Each DSR contains a high-performance control, sensing and communications module that enables exchanging messages with adjacent DSRs and a local network interface bridge (NIB). Secure communication takes place between the NIB, which acts as a local intelligent control agent, over a backhaul Internet-protocol connection to the smart wire system manager (SWSM), which manages the NIBs and their assigned group of DSRs.

Present and Future Needs

System analysis indicates DSRs can improve available transfer capacity. They also can be used to reduce the magnitude of loop flows, reduce contingency-induced overloads (N-1, N-2), support renewable integration, expand maintenance and construction outage windows, and defer line upgrades. Reducing a line flow by even a few percent can significantly defer upgrades and costs. Work is already underway to implement the concept in a state estimator, so optimal operating benefits can be planned for a complex interconnected grid rather than just on a line-by-line basis.

DSR technology offers transmission planners and operators a new tool that helps to address a wide range of issues facing utilities today. TVA stepped into a leadership role in the development, testing and trial of this technology.

The number of challenges transmission system owners must meet increases every year. Transmission owners and operators are asked to improve grid reliability, facilitate efficient electricity markets and integrate renewables. DSR technology has the potential to mitigate the problem of overloaded transmission lines; if the technology proves itself, the U.S. power grid will benefit.

DeJim Lowe ([email protected]) is the senior manager of grid modernization technology in Tennessee Valley Authority's technology innovation organization. He has been with TVA for 22 years, supporting both transmission and distribution research and development needs. His areas of support have included electric transportation evaluation, synchrophasor applications identification, substation efficiency evaluation and data integration for asset management.

Joshua Shultz ([email protected]) is an operations engineer in Tennessee Valley Authority's energy delivery, transmission and reliability organization. He has been with TVA for almost 10 years, filling both transmission planning and transmission operations roles. His research and technical interests include generator and voltage stability, optimal power flow and outage analysis.

Ian Grant ([email protected]) is the planning coordinator for Tennessee Valley Authority's energy delivery department. He has more than 40 years experience in transmission and system design. He previously held positions at Power Technologies Inc., General Electric Co. and The Electricity Commission of NSW in Australia. He has authored more than 50 professional publications and is an IEEE Fellow and CIGRÉ Distinguished Member.

Frank Lambert ([email protected]) serves as the associate director of the National Electric Energy Testing, Research and Applications Center at Georgia Tech. He is responsible for interfacing with NEETRAC's members to develop and conduct research projects dealing with transmission and distribution issues. Lambert previously worked at Georgia Power Co. for 22 years in transmission/distribution system design, construction, operation, maintenance and automation.

ARPA-E | arpa-e.energy.gov

Baltimore Gas & Electric | www.bge.com

Department of Energy | energy.gov

National Rural Electric Cooperative Association www.nreca.org

NEETRAC | www.neetrac.gatech.edu

Smart Wire Grid | www.smartwiregrid.com

Southern Company | www.southerncompany.com

Tennessee Valley Authority | www.tva.gov