The 320-kV direct-current (DC) France-Spain interconnection is a new link between the existing 400-kV alternating-current (AC) transmission systems in France and Spain, connected by converter stations located in Baixàs, France, and Santa Llogaia, Spain. The project is unique because of the difficulties the utilities — Reseau de Transport d Electricite (RTE) in France and Red Eléctrica de Espana (REE) in Spain — encountered in developing international interconnections on the European transmission systems.

In June 2008, France and Spain decided to establish an electrical interconnection between Perpignan, France, and Figueres, Spain, by establishing a DC underground cable using, wherever possible, the routes of existing infrastructure. The search for possible technical and environmental solutions for the underground cable route through the Pyrenees mountain range at the French-Spanish border highlighted the fact that only a limited number of options were available, which contributed to the complexity of finding a satisfactory solution.

The investigation initially focused on a route using a trench, but that was not possible. Thus, a tunnel solution was adopted to cross the Pyrenees Mountains. The underground cable route has an overall length of 64.5 km (40.1 miles), with 32 km (19.9 miles) in Spain and 32.5 km (20.2 miles) in France. In the tunnel, 8.3 km (5.16 miles) of cable is installed.

Determining Factors

The tunnel solution had fewer technical restrictions, and although it is used almost exclusively in urban areas and rural-urban transition zones, it also is being used increasingly in rural areas now. Therefore, it may seem the tunnel solution is suitable for all kinds of situations, but in fact, it is dependent on the characteristics of the terrain. The following aspects had to be considered:

• The maximum allowable gradients, which normally cannot exceed 10% longitudinally, in significant sections, and 3% to 4% transversely

• Unstable areas subject to flooding or with geological risks such as landslides and earthquakes

• The availability of a network of main roads so special vehicles could transport the cables to the splice/joint positions (for this project, the cable drums were more than 4 m (13 ft) in diameter and weighed around 80 tons

• The maximum length of intervening natural or manmade obstacles was no more than 600 m (1969 ft)

• The cables have been installed in a concrete trench approximately 1 m (3.3 ft) wide and 1.5 m (5 ft) deep, with a 1-m separation between the two circuits; thus, the total width of the installation is some 3 m (9.8 ft).

The tunnel solution for electricity cables has specific characteristics that clearly differentiate them from other tunnels (for roads, railways and hydroelectric plants), especially in the operational phase. These characteristics relate to the necessity of watertightness, restrictions on entry as a result of the presence of live cables, necessity of forced ventilation systems and so forth.

Whereas there is comprehensive legislation for other types of tunnel, in the case of electrical lines — although there are generic regulations for tunnels applicable during the construction phase — there are no rules for very deep tunnels designed to accommodate electricity cables.

International Interconnection

In the case of this interconnection, the situation was further complicated by being a cross-border tunnel. Two sets of regulations, in France and Spain, were applicable for the tunnel’s implementation and use, and the regulations were very different. Furthermore, there were differences because the project had two developers, RTE and REE.

The basic parameters considered in the tunnel’s design were as follows:

• Use of the tunnel

• Required diameter determined by the minimum distance between the cables, as specified by Prysmian, the appointed cable manufacturer

• Auxiliary installations

• Power supply system inside the tunnel

• Forced ventilation system.

The design also was determined by the construction risks, particularly the estimated time for completion as this determined the excavation system to be employed.

The basic natural determining factors are influenced by the geology. Key were the basic type of substrates (hard or soft rock, or loose elements); homogeneity or heterogeneity of these substrates; arrangement of the strata; presence of faults or other discontinuities; geological risks; stability of the massif; and underground hydrology.

It also was necessary to consider the social determining factors such as the proximity to the existing infrastructure, proximity to population centers and availability of existing infrastructure, which makes it possible to access the tunnel entrances and supply the equipment. Physical determining factors such as the availability of space for the necessary construction activities — around 3 hectares to 4 hectares (7.4 acres to 9.9 acres) — also were considered.

These basic aspects and risks could be controlled only by using very precise prior knowledge, based on geotechnical studies of the mountainous massif to be crossed. Therefore, studies were undertaken from the surface to determine the feasibility of the tunnel’s design and implementation.

Crossing Area

The area studied for crossing the French-Spanish border in the Pyrenees, a particularly mountainous area, was determined by means of the intergovernmental usage agreement that requires using the routes of existing infrastructure where possible. The area is a wide band with a north-south orientation, parallel to the route of the motorway infrastructure, main national roads and high-speed train. It also includes the upper part of the Roussillon plain and the Ampurdán plain, with foothills both to the east (the Albera Massif and the mountain ranges extend as far as the Cap de Creus) and to the west along the mountain range of Las Salinas and the Canigou.

With regard to the environment, it was noted a large part of the zone studied comprised protected areas that belonged to the European Nature 2000 Network: the Tech River, the Les Salines Massif and the Albera Massif, the Llobregat River in El Ampurdán and the Albera Ponds on the Spanish side. Finally, on the French side are two natural areas of ecological interest for wild fauna and flora on both sides of the valley, Vallespir to the west and the Alcornoques of Albères Forest to the east.

The passage through the Pyrenees involves stringent constraints with respect to the natural and social environment, heritage and countryside. The studies carried out, with the restrictions for laying cables determined by the current technology, meant it was not possible to find a trench solution, so the tunnel solution was adopted.

System Success

The four 320-kV DC cables have cross-linked polyethylene (XLPE) insulation that prevents the risk of fire and provides the interconnection a load-transfer capacity of two 1000-MW cables. These cables were transported to the site and a total of 144 splices/joints were completed on site, 12 of which were positioned in the tunnel. Two fiber-optic cables (48 fibers) were also installed for the protection, control and communications systems.

The two converter stations at Baixàs and Santa Llogaia, which were installed under a turnkey contract awarded to Siemens, were equipped with voltage source converters designed to reverse the power flow within 150 msec.

The interconnection had a budget of 700 million euros (US$747 million), of which 225 million euros (US$240 million) was funded by the European Union as it was a project of European interest. The interconnection was commissioned in 2014.

This new line has doubled the level of interconnection between France and Spain from 3% to 6%, which is still below the 10% minimum recommended by the European Union. This interconnection also has resulted in increased usage of renewable energy sources, improved supply security for customers and integration of the Iberian market into the European electricity market. ♦

Javier Arévalo Camacho is a forest and civil engineer who studied at the Polytechnic University of Madrid. He worked at INTECSA for five years on environmental impact studies on highways and other infrastructure. Arévalo has 26 years of experience working in the environmental department of Red Eléctrica de España on environmental and technical feasibility studies on overhead power line projects in 10 different countries. He was responsible for the design and construction of the Spain-France Interconnection tunnel.

Gregorio Denche Castejón was awarded his industrial engineer’s degree from the Polytechnic University of Madrid in 2002 and joined Red Eléctrica de España in 2003 in the engineering lines department. Denche has been the technical manager for several underground and submarine projects that have included the second electrical interconnection between Spain and Morocco; the electrical interconnection between the Spanish mainland and the Balearic Islands; and the electrical interconnection between France and Spain.

José Manuel Argüelles Enjuanes was awarded his industrial electrical engineering degree from the Gijón Polytechnic School of Engineering in 2006. Initially, he worked for Socoin Ingeniería y Construcción Industrial in the new developments transport and distribution department. Argüelles then joined Red Eléctrica de España in 2009 to work on the electrical interconnection between France and Spain, for which he was involved in the cable system design and construction of the link.Sidebar:

Sidebar: Cable Tunnel Design

Although the technical requirements differ between the high-speed rail line and underground electrical connection, the high-speed rail tunnel that crosses the mountainous area was considered a possible solution. However, the design of the tunnel was not suitable for the electrical interconnection. The optimum solution was the tunnel running in parallel and close to the rail tunnel, while maintaining the necessary safety distance between the two.

Most of the tunnel excavation of 8.1 km (5 miles) was done using two double-shield tunnel-boring machines. The double-shield design enables them to operate in areas of complex geology with heterogeneous formations, and they have very good rates of progress through hard, soft and fractured rock, and through faults such as those encountered when crossing the Pyrenees. The Reseau de Transport d Electricite (RTE) in France and Red Eléctrica de Espaňa (REE) in Spain designed the tunnel with the following key features:

• The tunnel follows a route parallel to the Perpignan-Figueres high-speed rail line. It is virtually a straight line with slight bends having curvature radii over 100 m (328 ft).

• The south entrance (on the Spanish side) uses the same platform used in the construction of the high-speed rail tunnel, thus avoiding further modifications to the

surrounding environment.

• The north entrance required removal of trees in an area of Mediterranean forest. An area of more than 4 hectares (9.9 acres) was required to install the tunnel-boring machines.

• The main section of the tunnel has an interior diameter of 3.5 m (11.5 ft) and an exterior diameter of 4.2 m (13.8 ft).

• The tunnel maximum gradient is 2.35%.

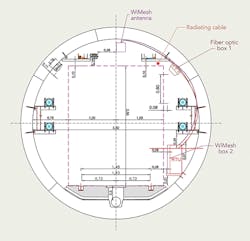

• The two 320-kV circuits, each comprising two cables, were installed on either side of the tunnel.

• The cables were pulled into the tunnel from each end of the tunnel.

• Special sections for transformers and cable joints run along the length of the tunnel.

• The cable joints are placed vertically inside the tunnel at regular intervals. Each cable joint occupies a length of 5 m (16.4 ft).

• To comply with the Spanish operating regulations, the tunnel is accessible by a robotic vehicle, guided by grooved rails, to be used for maintenance work.

• Auxiliary equipment is installed along the length of the tunnel (lighting, electrical outlets, transformers, fiber optics for temperature control and wireless mesh network).

• The forced ventilation system is housed in the entrance buildings and is used to control the temperature in the tunnel when the interconnection is in operation.

The construction of the tunnel is complicated, especially given the variable geological characteristics, the crossing of faults and the subterranean rivers. In these areas, it was necessary to carry out additional activities to resolve the associated problems (that is, the use of special foams to facilitate the progress of the tunnel-boring machines or controlling the entry of water).