Rapid deployment of distributed energy resources on utility-owned distribution feeders is creating new technical and safety concerns. When the utility supply is interrupted, the circuit downstream of the open point may remain energized by interconnected distributed energy resources (DER), creating an electrical island.

Island conditions sustained by DERs beyond the two seconds required by standards present both a safety risk and significant operational challenges. At worst, they damage connected load or create a safety hazard if they continue to energize line sections already identified as faulted by the utility protection system. At best, they maintain proper voltage and frequency; however, they still hinder restoration or operation of automatic reclosing and distribution automation schemes, affecting reliability.

Inverter-based DERs must detect island formation and disconnect from the system in less than two seconds, per the IEEE 1547 interconnection standard. However, island detection at the DER location can be complicated by multiple DERs on the same feeder. Sandia National Laboratory cautions that the following conditions, which are becoming more common, can weaken a DER’s ability to detect an island: cases with very large numbers of inverters, cases with inverters from several different manufacturers, and cases including both inverters and rotating generators.

Additionally, rapid DER growth has resulted in deferment of many transmission and generation projects, which has increased reliance on DER to provide base-load generation. IEEE 1547-2018 establishes new stringent ride-through requirements to ensure the DER remains on-line during bulk system disturbances by delaying or desensitizing the DER’s voltage and frequency settings. Consequently, delaying DER’s local anti-islanding algorithms may become necessary to meet these requirements. Alternatively, a communication-based anti-islanding system—providing the status of each midline device—eliminates this concern by giving a more accurate and immediate indication of connectivity to the DER.

Anti-Islanding Approaches

Anti-islanding generally falls in two categories: passive or active local detection schemes and communication-assisted schemes. The passive local systems generally rely on local voltage and frequency to detect an island. Active local schemes intentionally perturb the generator frequency, which only an islanded system follows. Local detection schemes tend to be designed with security in mind, to maximize generation and minimize nuisance trips. These systems sacrifice dependability because they enable generation to persist if island occurrence cannot be positively detected. Additionally, local detection schemes become less dependable when multiple DERs are present on the circuit.

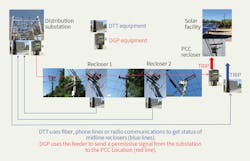

In contrast, communication-assisted schemes tend to be designed with dependability in mind to minimize the risk of island formation. Communication-assisted schemes send information from the utility to supervise when the DER can generate. Direct-transfer trip (DTT) systems, which transmit a trip signal when an isolating device has opened, fall in this category.

A DTT scheme monitors the status of each midline recloser between the utility source and DER, using separate communication channels. A central controller at the distribution substation monitors these reclosers and sends trip signals to the appropriate DER disconnecting device if a midline recloser opens. Since a DTT system mimics the arrangement of isolating devices on the distribution circuit, configuration changes (additions, removals, relocations) require corresponding changes to the mimicked DTT system.

New Approach

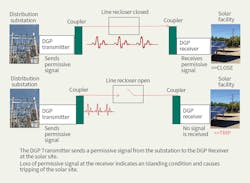

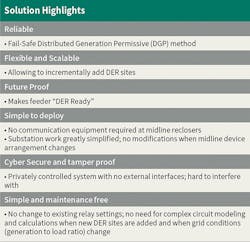

Distributed generation permissive (DGP) is a new communication-assisted approach developed by GridEdge Networks, a technology firm specializing in modern grid applications. DGP uses a simple fail-safe technique that continuously monitors the connection between the utility and DER. Using power-line communications, an encoded permissive message is continuously sent across this path. The receipt of it permits DERs to generate. The absence of the DGP signal for a predefined time forces the DER off-line.

The permissive signal is controlled at the substation by contact inputs to the transmitter, which provides validation of utility supply to the circuit. Any open point on the circuit between the substation and DER—whether by an open midline recloser or broken phase conductor—interrupts the DGP signal, forcing downstream DERs off-line. The DGP system is highly dependable because any communication equipment failure will result in a loss of the permissive signal, forcing the DER off-line. DGP does not employ any external communication channels.

This design significantly reduces the possibility of false-negative outcomes, by forcing loss of communications—the most likely failure—to yield false-positives outcomes. Such occurrences should be uncommon, but emphasizing dependability is necessary to protect a utility’s assets and its customers during sustained communication failures.

Presently, DGP is installed on dozens of Eversource Energy distribution circuits, ranging from 13.2 kV to 27.6 kV. The signal is placed on two primary conductors using a pair of medium-voltage couplers. Signal coupling to two phases ensures high availability, redundancy and common-mode noise rejection. Signal regeneration is used on circuits where required. Regeneration reconstructs the DGP signal and removes conducted noise.

The DGP system also collects signal-health statistics in real time. This digital system requires no wave traps because it uses multiplexing techniques to support multiple signals on the wire. The DGP signal includes a digitally encoded message that identifies the feeder to which it is attached. Multiple circuits can be tagged at a station using this technique. Signal encoding also can be used to send control messages for DER operating-mode changes, export curtailment, volt-ampere-reactive (VAR) support and more. Eversource Energy has used DGP to protect many different types of DERs. The utility’s accumulated experience with it now exceeds four years, and it has found the overall reliability of DGP to be excellent. After installation and commissioning, communication failures have been rare.

DGP Installation

The first Eversource Energy circuit using a DGP system was installed in 2013. After installation and tuning, an outage simulation was performed that caused the DER to trip successfully. The system passed various additional tests and has been in service successfully for nearly five years. The DGP system became a standard method for the utility in 2015.

Another relevant islanding issue is the effect of DER on automatic reclosing practices. The IEEE 1547 standard requires a DER to disconnect within two seconds following a fault interruption. If a utility normally recloses in less than two seconds following such an interruption, the DER could still be on-line and the reclose attempt could be out of phase. To avoid this, the utility would have to delay its reclosing time interval or use a reclose-blocking scheme whenever a load-side voltage is detected. Reclose-blocking schemes delay restoration, add cost and, most importantly, do not eliminate island formation. Individual DERs must still disconnect themselves from the islanded circuit, an act that can be impeded when multiple DERs are present.

High-Penetration Installation

Eversource has installed DGP on one of its distribution circuits containing 10 independent power producer’s solar photovoltaic (PV) sites. The first location for interconnection contained three DER sites connected through a single-line recloser equipped with a single DGP receiver. Subsequently, seven more locations were connected, each containing a single DER site connected through a discrete line recloser equipped with a DGP receiver.

The DGP permissive signal is coupled to the circuit at the substation by a single transmitter. The signal then propagates along the line and regenerates as needed (seven regenerator locations were required for this circuit). Each DGP receiver is tuned to sense this common permissive DGP signal and designed to trip its corresponding DER facility if the signal is not present at the PV location. During abnormal conditions, DGP receivers located beyond an open recloser or broken phase conductor will lose reception of the permissive signal and trip their respective DER.

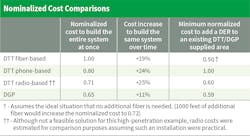

A cost-benefit analysis for this high-penetration circuit demonstrated the cost-effectiveness and scalability of the DGP system versus a traditional DTT implementation. The DGP system uses 17 termination devices and no external communication devices. An equivalent DTT solution would require 30 termination devices as well as 15 external communication lines to communicate with each of the DER locations and gather the status of each midline recloser. Any future DER additions or circuit rearrangements would require additional DTT communication lines and reprogramming of the controller logic.

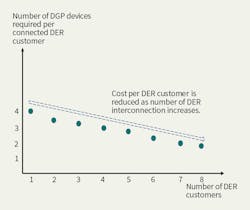

Once the DGP signal is installed on a circuit to supply initial DER installations, future DER applicants only need to install a DGP receiver and possibly extend the DGP signal to their interconnection point. As a result, the marginal cost curve for additional DER installations has a downward slope, as a larger percentage of the circuit is covered already by the DGP signal.

Significant conclusions from the costing analysis are as follows:

- It is most economical when several DER customers are

on the circuit. - The cost increase to install the same equipment over time as each DER customer comes on-line shows DGP is the more economical approach for communication-assisted, anti-islanding protection on high-penetration circuits. Building out the DGP system over time carries comparatively little additional cost, mainly because no additional substation work is required.

- The normalized cost to provide communication-assisted, anti-islanding protection for a new DER customer on a circuit already equipped with the technology is minimized. Except where fiber is present already at the point of common coupling, DGP is the least costly method.

DGP Effectiveness

The rapid increase in DER installations led to more stringent ride-through and related requirements, raising concerns that autonomous, local anti-islanding schemes would become less reliable. Consequently, the anti-islanding concept of DGP was developed and deployed on dozens of Eversource Energy distribution feeders, some up to 20 miles (32 km) long.

With more than four years of in-service experience, the utility’s DGP solution has proven to be a reliable, cost-effective and easy-to-install option for maintaining utility control of distributed generation. Because DGP propagates the signals through utility conductors, no external communication medium is needed. This makes the utility independent of third-party communication providers (for example, leased phone lines) and eliminates line communication costs. DGP can be installed quickly, easily accommodates reconfiguration of midline devices and economically scales with DER growth.

Because of its use of utility overhead wires, DGP is a relatively tamper- and hacker-proof technology. Utility liability is minimized when an optimized, utility-controlled anti-islanding technology, such as DGP, is selected.

These real-life examples have demonstrated DGP is often lower cost than other forms of DTT, especially on circuits with high penetration of DER. This enables the utility to cost effectively maintain reliable control over interconnected generation through communication-assisted schemes.

On circuits where DGP is present already, the digitally encoded messaging capability may provide an inexpensive opportunity for utilities to maintain control of DERs that would not otherwise require DGP. The ability of DGP to place a unique signal on the circuit and send simple control commands enables utilities to offer DGP applicants an alternative to more costly modifications that otherwise would be required to maintain proper operational control of the distribution system (for example, reclose blocking, output curtailment during abnormal conditions or alterations to accommodate distribution automation schemes).

The DGP signal can be easily extended on the circuit as needed. It can incorporate source information and inherently monitor the status of supplying conductors and in-line devices to provide confirmation of circuit continuity to each DER customer. This is a simpler and more dependable approach to anti-islanding detection.

Once DGP is installed on a circuit, future DER installations can be readily added at a small incremental cost, with shorter deployment times and without the need for system changes.

Essentially, the circuit can be considered DER ready.

Michael S. Costa ([email protected]) is a principal engineer with Eversource Energy. He has 35 years of experience in the protection and controls engineering department, with a strong focus on distribution automation using distribution supervisory control and data acquisition (DSCADA) operable overhead-line reclosers with loop-scheme technology. He has been instrumental in developing protection systems for arc-flash mitigation and incorporating distributed energy resources on Eversource’s distribution system. He earned his MSEE degree from Worcester Polytechnic Institute and his BSEE degree from University of Hartford.

For more information:

Eversource Energy | www.eversource.com

GridEdge Networks | www.gridedgenetworks.com