The Tohoku region of Japan has ideal wind conditions. By the end of 2015, Tohoku Electric Power Co. Inc. had connected 800 MW of wind power to its medium-voltage network. At 26%, this was the largest share of total installed wind power capacity in Japan. Because of the favorable feed-in tariff, the utility decided to increase the installed wind power capacity connected to its medium-voltage network to 2510 MW. From a solar standpoint, at the end of fiscal year 2015, the utility had connected approximately 2450 MW of solar power to its grid. This makes Tohoku EPCO the second-largest utility in Japan in terms of the ratio of solar power output to the maximum electricity demand.

With this increase in intermittent weather-dependent wind and solar photovoltaic generation capacity connected to the network, concerns have been growing about electric power quality, including voltage and frequency fluctuations. At present, frequency regulation is addressed by adjusting the electricity generated by thermal power plants, but there is a finite limit to the effectiveness of this adjustment. To evaluate these concerns, Tohoku EPCO has installed a large battery energy storage system (BESS) in the Nishi-Sendai substation to demonstrate the effectiveness of the BESS at regulating frequency. Effective frequency regulation would enable the utility to increase its use of renewable energy.

System Overview

The BESS has an output of 20 MW, a short-time rating of 40 MW and a storage capacity of 20 MWh. Supplied by the Toshiba Corp. Energy Systems & Solutions Co., the BESS is designed to provide 20 MWh of charging/discharging at the medium-voltage network connection point for 20 years. It has been installed with the aim of reducing grid frequency variation due to an increase in intermittent weather-dependent wind and solar photovoltaic power generation.

The battery is charged and discharged in response to commands from Tohoku EPCO’s control center, and it is operated in conjunction with a thermal power generator. It is used mainly for network frequency regulation applications, which were solely handled by thermal generators prior to the installation of the BESS.

A BESS can provide a faster tracking speed than a thermal power generator, but the time in which a battery can provide continuous charging/discharging is restricted by its capacity, overheating tendency and other factors. For these reasons, the use of a BESS together with a thermal power generator was considered to further improve the frequency regulation capability. Tohoku EPCO has 13 thermal plants, with a total generation capacity of 12,725 MW.

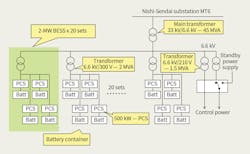

The BESS consists of the following components: a main voltage transformer (45 MVA, 33 kV/6.6 kV); 20 step-up voltage transformers (2 MVA, 6.6 kV/300 V); two on-site voltage transformers (1.5 MVA, 6.6 kV/210 V); 80 power conditioning system (PCS) units (500 kW); 80 storage battery containers; and a control protection system.

BESS Functions

Notable challenges experienced in the design of this BESS project included a service life of 20 years, accurate management of the state of charge (SOC) of a huge number of batteries, and the control of distribution of the charged and discharged power to 80 PCS units.

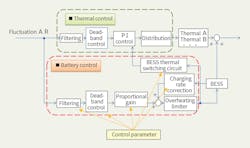

The load frequency control (LFC) system calculates the demand-supply imbalance in different localities of the service area, referred to as the area requirement, which is based on frequency and electricity flow deviations. The LFC system adjusts outputs from the thermal power generator and BESS accordingly to keep the area requirement within a given range. The LFC loop consists of a control path for the existing thermal power generator and another control path for the BESS. These two control paths have similar structures.

The charging rate correction function is unique to the BESS. To take advantage of the high dispatch ability of the BESS, time constant and other parameters to the input filter are designed to be programmable separately for the BESS and the thermal power generator. The battery control path takes the area requirement as input and provides a control command value through a filtering unit.

Following is an outline of the control blocks for the LFC:

• The filtering unit performs band-pass filtering to acquire short-period data input to be passed onto the BESS from the area requirement.

• The dead-band control unit activates the BESS only when the acquired short-period data input exceeds a given threshold, to reduce the electrical energy to be charged and discharged.

• The charging rate correction unit adjusts the value of the charge/discharge command so the battery charging rate will reach the target.

• The BESS thermal switching circuit gradually hands over the amount of LFC control from the BESS to the thermal power generator to prevent batteries from being charged and discharged continuously over a long time, so the BESS maintains a certain adjustment capacity.

• The overheating limiter calculates the electricity being charged and discharged as well as limits excessive battery charging and discharging when a given threshold is exceeded, to prevent overheating.

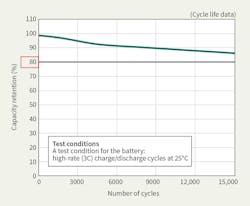

Life and Performance

To realize a BESS with a service life of 20 years, Toshiba’s SCiB lithium-ion rechargeable battery was deployed. Unlike its counterparts, SCiB maintains more than 80% of its full capacity after approximately 15,000 charge/discharge cycles. In addition, the SCiB does not exhibit significant degradation even when it undergoes the frequent charging and discharging required for frequency regulation applications. The proven robustness of the SCiB cells used within the BESS guarantees the longevity of the system’s service life, enabling it to meet the specified 20-year requirement.

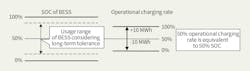

The SOC represents how much energy is left in a battery. The units of SOC are expressed as percentage points (0% = empty; 100% = full). The BESS for the Nishi-Sendai substation is designed to provide the initial capacity needed when a long service life is taken into consideration. Therefore, a SOC of 50% was chosen as the baseline.

To enable charging and discharging of 10 MWh, the BESS consists of batteries with a total rated capacity of 20 MWh. The operational charging rate is defined with 20 MWh being 100%. In other words, a 50% operational charging rate is equivalent to a 50% SOC. This definition enables the BESS to be used without any concern about capacity degradation caused by aging.

Furthermore, because of the use of high-accuracy SOC management technology, the BESS enables continuous operation without the need to be turned off for SOC correction.

Control Method

The BESS receives an effective power command from the control center every five seconds. If the output control commands (charge/discharge) from the PCS units are out of balance, individual batteries will receive different control signals. To resolve this issue, a technique for equally distributing the electrical energy to be charged and discharged to all batteries has been developed.

With this technique, parameters set as charge/discharge commands are split among PCS units at a given interval based on their charge/discharge efficiency, operating time and SOC of individual batteries. These are then used to turn on the PCS units accordingly. This technique has enabled high-efficiency operation of the PCS units. By reducing the burden of varying and inconsistent control commands on batteries, it is also expected to help reduce long-term battery degradation.

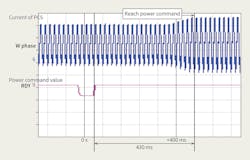

One of the major characteristics of a BESS is the fast charge/discharge cycle. The BESS is designed with a set target time from when the control equipment receives a charge/discharge command to when the PCS units begin charging or discharging at 1000 msec or shorter. It takes approximately 430 msec for the discharge electricity to arrive at the network after the command is received, including the time taken for the control equipment to process the command, the transfer time from the control equipment to the PCS units and the PCS latency. It was considered the BESS provided high dispatch ability performance.

Construction

The major components of the battery system are the battery module and battery panel installed in containers, with each component being supplied from different locations. The battery modules first are installed in the battery panel before being transported to the site. The battery containers are directly transported to the site and provide a battery storage capacity of 20 MWh. A total of 80 battery containers have been installed at the Nishi-Sendai substation

Construction was completed in three phases: base, civil and electrical. To minimize the construction period, the battery containers were installed in four groups of 20 units. This enabled the construction phases to be completed in parallel during an 18-month period that included both testing and commissioning.

Project Success

Because of this project, an optimal control method and management technology for BESS was developed. The BESS has been in commission at the Nishi-Sendai substation since February 2015 and, based on the results of this operational period, its performance to date has been deemed a success. The demonstration project ended in January 2018.

Acknowledgement

The authors wish to acknowledge the support and technical advice given by Dr. Daisuke Takeda and Tatsuya Hashimoto of Toshiba Corp. in the preparation of this article. ♦

Mitsuhiro Matsumoto has been working for Tohoku Electric Power Co. Inc. since 1991. He is now manager of the power system control design engineering group in the power system engineering department, where he oversees scheduling and operation of electric power systems. Matsumoto was a member of the advanced power engineering team at Tohoku University from 2013 to 2015.

Eiji Matsuzaka has been working for Tohoku Electric Power Co. Inc. since 1988. He is manager of the hydropower and substation engineering group in the power system engineering department, where he oversees scheduling and operation of substations. He used to be the general leader of the group to maintain 40-MW, 40-MWh large-scale battery storage systems located in Minamisōma, Japan.

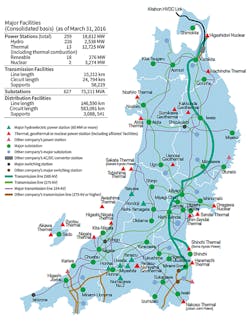

Sidebar: About Tohoku EPCO

A large vertically integrated utility located in the north of mainland Japan, the Tohoku Electric Power Co. is responsible for generation, transmission and distribution of electrical energy. The utility has a portfolio of 259 generating stations, with a total installed capacity of 18,812 MW, consisting of 226 small hydro stations (2538 MW), 13 thermal power plants (12,725 MW), two nuclear power plants (3274 MW) and 18 renewable energy facilities. The extensive transmission system has a circuit length of 24,794 km (15,407 miles) with operating voltages of 500 kV, 275 kV and 154 kV. The 627 extra-high-voltage/high-voltage substations installed supply the high-voltage, medium-voltage and low-voltage distribution network, which has a circuit length of 583,091 km (362,333 miles).

Check out the March 2018 issue for more articles, news and commentary.