Arizona Public Service Leverages Data for Advanced Distribution Management

Every day, a deluge of raw data pours out of smart meters, remote terminal units in substations and even some telemetered field devices. Arizona Public Service Co. (APS) embarked on an ambitious journey to deploy an advanced distribution management system (ADMS) to take advantage of this abundance of data. Among the goals was to maintain reliability, extend the life of valuable assets, avoid unplanned service outages, isolate outages and locate problems to send repair crews to exact locations as well as cut down on restoration time.

ADMS merges information technology with operational technology. The system provides grid operators visibility into what is happening on the grid. It also provides access to information needed to supply quality power during changes in demand, such as during Arizona’s hot summers when air conditioners are working hard.

Starting Point

Like all utilities, APS faces many tough challenges on the path to making the electric grid work more efficiently. Some of these challenges come from the utility introducing new technology and practices that provide its customers greater control over how they use electricity. For example, APS provides time-of-use plans that encourage customers to shift their electricity use from more expensive peak periods to cheaper off-peak times, placing customers in control of their usage.

Another example is solar power, which is a source of distributed generation. In 2008, APS had fewer than 200 solar customers; today, it has more than 78,000. Now a single distribution feeder can be connected to more than 500 solar generators, presenting a unique challenge for grid operators.

Around 2010, APS realized its distribution operations management system was not scalable and would not be able to handle the growing advanced grid technologies coming online. The utility began an intensive planning effort in 2013 for a replacement system. It needed a dynamic, flexible grid management system with greater visibility, control and automation of the distribution grid. Through a rigorous request-for-proposal (RFP) process, APS ultimately selected Schneider Electric to implement its ADMS software suite. Schneider also made recommendations regarding architecture and hardware, and trained APS staff on what was required for implementation of the ADMS solution.

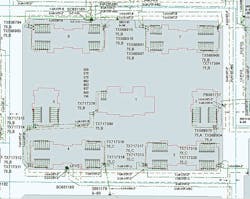

Enabling an existing geographic information system (GIS) network model as a primary source of data was key to the success of APS implementing ADMS. A GIS network model is a database that provides a flexible way of representing objects and their relationships. Think of it as a picture book with layers that can be drilled down into; without this visualization of the network connectivity, the book is just text and no illustrations.

In support of the ADMS data requirements, POWER Engineers Inc. provided APS with a complete and detailed network model review from substation breaker to meter. POWER used its knowledge of the electric grid and GIS to add detail to the network model. This included the secondary and dedicated networks in a dense downtown area, hence the need for more layers to support the ADMS. POWER also set up stitching points where substation internals were aligned with the GIS and provided extensive quality assurance routines to ensure data integrity.

Improved Data Quality

APS began cleaning up its data to support the implementation of ADMS. The utility knew improving data quality and gathering the right data would take considerable time and effort. At this stage, APS stepped through pilot data sets, data modeling sessions, factory acceptance testing and system acceptance testing. The main challenge was modeling the network while considering unique system construction practices and equipment. As another precursor to the ADMS project, APS recognized the need to revise its GIS architecture, including its aging Visual Basic 6 (VB6) code and other custom applications. To address this obstacle, POWER converted roughly 1 million lines of VB6 code and greatly reduced the amount of custom code to increase APS’s flexibility, mapping productivity and data quality.

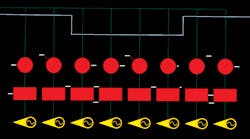

APS focused intensely on data integrity, which can take many forms in a network model — from domain values aligning with engineering industry standards to field-settings data linking to critical assets, such as reclosers and sectionalizers, capacitor banks, switches and breakers. Correct phasing also is important for properly modeling the system and providing increased visibility of the complete feeder.

APS started with a complete review of the data needed to support the initial phase of the ADMS implementation. For the GIS, this included two system updates addressing known modeling deficiencies, which was necessary to ensure key data was modeled properly for the distribution feeders. In support of the second ADMS phase, APS completed two more GIS model updates for additional quality assurance and quality control tools. Completion of a fifth update supported supervisory control and data acquisition (SCADA) mapping for communications and control from the distribution operations center.

Implementing new quality-assurance tools, coding routines and other data-quality steps enabled APS to import solid, workable data into the ADMS. The new system incorporated a robust process for front-end quality control, reconciliation and posting.With improved data integrity, the new ADMS enables operators to support the distribution system with more advanced functions:

- Load management

- Restoration switching analysis

- Electronic switching orders

- Tags and clearances.

Another advanced function is a training simulation to test against historical events as well as proposed growth, enabling analysis without affecting daily operations.

The result is a network model capable of providing system operators the best data for analysis. APS can manage its distribution networks while making better operational decisions for the grid.

A Good Model

GIS network models, which are visual and layered, enable users to identify circuits and infrastructure — such as substations, lines, transformers and customer service locations — in the real world. Knowing asset locations, capabilities and their relationship to one another is fundamental to managing them. As opposed to single-line schematics, network models give grid operators greater flexibility to analyze system data, perform switching activities and manage the distribution grid efficiently.

APS’s legacy GIS model was built as a mapping tool using Esri’s base software and Schneider’s ArcFM extension for creating, managing, editing and modeling facility data. The GIS needed to be configured to feed more data to the ADMS in addition to meeting APS’s unique needs.

Working with POWER, APS added new values to the GIS and incorporated some equipment catalog tables. Together, they also enabled the ADMS network to pull GIS data from secondary conductors that were beyond the typical transformer-to-load relationship.

APS faced some unique issues in maintaining customers who are connected to substations under the jurisdiction and control of neighboring electric utilities. These nuances needed to be modeled correctly so APS would have proper information to respond to customer outages.

The POWER team mapped and modeled the downtown Phoenix networked secondary system, which paralleled transformer-to-meter connections, to make it part of the GIS data source for extraction to the ADMS. Detailed modeling of downtown Phoenix at the distribution level proved especially challenging because much of it was underground in a dense urban area.

Using a real-world approach and automated feeder management tools made it possible to stop a feeder’s identity and upstream flow at the low-voltage network protector. This enabled proper load flows and reverse flow protection when supplying large customers from multiple feeders and large transformers.

A Better Picture

After almost three years, APS’s ADMS went live in January 2017. After two days, the old outage management system was put into historical hibernation. The launch was a huge success with a large penetration of end users immediately leveraging tools beyond first-month targets.

This new system enabled the utility to get a better picture of the connections between all parts of its distribution network. By reconfiguring the GIS model, aligning it with a solid common information model and improving data integrity, APS gained the ability to manage the delivery of distributed power efficiently through nearly 1400 distribution feeders across the state. The system improved real-time communication between the operations center and field personnel, especially during outage responses.

APS’s ability to control lines remotely played an important role in the utility’s response to the Goodwin fire, which consumed 25,000 acres (10,117 hectares) in the Bradshaw Mountains of Arizona in June 2017. APS crews worked long hours coordinating with state and local officials to de-energize power lines and help to ensure the safety of emergency crews as well as residents. After fire crews from across the U.S. extinguished the blaze, APS quickly and safely restored power as residents returned to their homes and businesses.

The system also has given operators a better view of distributed energy resources connected to the grid, such as rooftop solar systems, to help them manage power flow more effectively and strengthen reliability.

With all its new functions and tools, the ADMS required extensive training and a coordinated change management process. It was important to have training materials, manuals and other support in place, so employees could take on their new tasks. Implementing ADMS and managing the changes it brought was not trivial. APS would advise any electric utility planning to implement ADMS to start small and use the major drivers as a starting point for action.

The ADMS is aligned with APS’s smart grid road map.

The new system is expected to reduce human error, improve safety, increase situational awareness, enhance system performance and strengthen reliability for the utility’s 1.2 million customers.

David Hopson ([email protected]) is an IT project manager III at Arizona Public Service Co. He is responsible for the network model upgrades and edge system integrations for the advanced distribution management system.

Larry Wilke ([email protected]) is a senior consultant at POWER Engineers Inc., where he specializes in data sourcing and integrations for advanced distribution management systems.