About 30% of all accidents occur while vehicles are moving in reverse, and thousands of children die or are injured each year due to backing incidents. While working in a residential area or backing up in any scenario, linemen can put themselves at risk for an unnecessary and life-changing accident.

At Ameren Illinois, field employees log more than 25 million road miles annually. To educate its field workforce about the dangers of operating a vehicle in reverse, Ameren Illinois turned to a training program called Safe Start, a registered trademark from ElectroLab Ltd. The utility also implemented safety strategies and invested in new backing assistance technology for the Galesburg, Illinois, operations fleet.

Sharing Knowledge with Field Crews

A year-and-a-half ago, the manager in Ameren Illinois' Division I turned to four field professionals to perform research on backing accidents and then share the information with other field crews. After reading story after story about parents and grandparents accidentally backing over their loved ones, the linemen made it their mission to educate others about how to eliminate backing accidents at home and at work.

The linemen searched for facts and statistics online, collected their personal stories and then created a PowerPoint presentation to present to their coworkers. So far, the linemen delivered the presentation at every operating center within Division I as well as at the statewide safety kickoff. Ameren Illinois is also training the new hires on the dangers of backing so they can develop safe driving habits from their first day on the job.

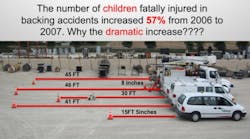

As part of this project, the team worked on identifying the size of the blind spot for each type of vehicle in their utility's fleet. According to research, larger, longer and taller vehicles like bucket trucks and line trucks have significant blind zones, and, as such, about 60% of backing accidents involve larger vehicles such as trucks or vans. To pinpoint the exact length of the blind zone, Ameren Illinois linemen parked their vehicles, and then had an individual walk from the back of each vehicle with a cone. As the coworker walked away from the vehicle, the driver honked the horn as soon as they were able to see the cone in the rearview mirrors. While the blind zone behind a normal van was about 15 ft, 5 inches, it jumped to 46 ft for a line truck.

This research opened the linemen's eyes to the hazards of operating large utility trucks while in reverse. While they can see everything in front of them as they drive forward, most had never contemplated the hazards associated with putting their vehicles in reverse. The Galesburg Operating Center may not have encountered a significant backing incident up to that point, but the potential always existed since they often work in congested residential areas.

Creating a Video Presentation

In order to keep their coworkers safe while driving, the four Ameren Illinois Division I linemen also created a video about the risks involved with vehicle backing. They worked with Ameren Illinois public relations department and a video contractor to produce a Safe Start vehicle backing video, which has been made available companywide.

The video is about 7 minutes long and was an additional menu item on Ameren Illinois' Actions Matter Video, a quarterly video news magazine shown to Ameren Illinois coworkers. In addition, the video is available on Scholar, the company's online Intranet.

The video includes a variety of safety data and personal stories regarding family or friends whose lives were changed by unsafe acts. While it incorporates many safety lessons, the main message encourages employees to avoid backing a vehicle while at work and at home. Backing tips include pulling though a parking space if possible, backing into a parking space upon arrival, or using a spotter if backing into or out of a space is necessary.

Through the Safe Start training program, Ameren Illinois employees learn to identify four states of mind — rushing, frustration, fatigue and complacency — that cause individuals to make errors, increasing the risk for accidents and injuries. And these four states lead to four critical errors: eyes not on task, mind not on task, being in or moving into the line of fire, and losing your balance, traction or grip. This state-to-error pattern significantly increases the risk of injury in all types of situations, especially while driving.

Investing in New Technology and Training

Ameren Illinois linemen now have a new view of the dangers of vehicle backing, and they're required to follow new safety procedures. For example, at Ameren Illinois, employees aren't allowed to back a utility-owned vehicle without first designating a person to serve as a spotter. All the field professionals from the gas, metering and line departments are on board with this new safety strategy, and if they see a fellow coworker trying to back out of a spot, they will stop what they are doing and help back him or her out.

If the linemen are working alone and don't have access to a spotter, then they must first perform a “circle of safety,” a complete walk around the vehicle to look for hazards or obstacles like fire hydrants or pedestrians that may not be visible through rearview mirrors.

Another way the linemen are eliminating backing accidents is by relying on a new radar system from PreView Radar Systems. The Galesburg Operating Center is piloting this device, which measures about 4 inches tall and 6 inches wide and is mounted on the back of the vehicle. A 3-inch by 3-inch box with a series of lights and audible alarm is also installed in the cab of the truck. If the truck gets within about 10 ft of an obstacle, one light will show up, and then as the driver gets closer, the beeps will become more frequent, and more lights will illuminate on the device.

Currently, every line, metering and gas truck within the fleet at the Galesburg Operating Center is experimenting with a radar device, while some of the older trucks previously featured backup cameras. The utility used to equip vehicles with backing cameras and a monitor installed on the dash, but found that they provided a distraction within itself. In some cases, the drivers were so focused on the monitor that they chose not to use the side rearview mirrors, in turn, creating another hazard.

Although the radar devices can cost up to $800 each, the Galesburg Operating Center thought that for its purposes, it was a wise investment. By equipping its field crews with these devices, the utility is giving the linemen peace of mind and the ability to become safer on the road.

Routinely working safely doesn't deliver instant gratification, however, says Derek VanUnnik, electric crew leader at the Galesburg Operating Center.

“There's no adrenaline rush or excitement of something almost happening,” he says. “The satisfaction is going home to your family knowing everything went well that day.”

Gabe Jones ([email protected]) is a journeyman lineman and has been with Ameren Illinois for almost five years. His crew performs overhead and underground maintenance as well as new construction. He partnered with Jerry Brewer, journeyman gas serviceman, Peoria, Illinois; Ed Jackson, electric substation apprentice, Galesburg, Illinois; and Derek VanUnnik, electric crew leader, Galesburg, on the video and educational presentation.

Editor's note: EUO readers can order the video by calling 314-554-2807 or view it online at http://youtu.be/7-CbZ0E8qNI.

Companies mentioned:

Ameren | www.ameren.com

ElectroLab Ltd. | www.safestart.com

Preco Electronics | www.PreViewRadar.com