Linemen Get Up to Speed on Fall Protection

When the Occupational Safety and Health Administration (OSHA) passed its new fall protection regulations in April 2014, electric utilities across the country encountered major challenges in preparing and equipping their workforce for compliance within a year.

Western Area Power Administration, however, took a proactive and collaborative approach toward implementing the necessary changes, starting with top-level commitment from the organization’s senior leaders and maintenance managers.

With dedicated staff, time and funding committed to compliance, teams of subject-matter experts began tackling the multitude of changes and issues in fall protection: linemen rewrote their fall protection manual; engineers evaluated steel tower anchorage points to retrofit towers; craft communities developed and held new training; and the agency worked with other utilities and third-party vendors to identify best practices, tools and equipment for crews to continue their work safely with minimum interruption. Western’s goal was to create a culture that exceeded compliance and focused first on ensuring everyone returned home safely.

Translating Information to Practice

Western recently focused on training in its journey to compliance. Craft-specific teams on Western’s fall protection committee shared information, procedures and personal protective equipment (PPE) with their colleagues to prepare them for implementing the regulations by April 1, 2015. Western organized a Train-the-Trainer event for its electricians and electronic communications fall protection coordinators the week of March 2 at Mead substation in Boulder City, Nevada. The trainers then shared the skills they learned with crews in their home states and regions.

For the linemen, however, Western opted not to take its traditional Train-the-Trainer approach because the changes in the rules were so significant and the topic — fall protection — has life or death consequences if not performed correctly. Instead, Western sent all 25 line crews, totaling about 150 linemen, from its four regions — Desert Southwest, Upper Great Plains, Sierra Nevada and Rocky Mountain — to Mead substation in February and March to provide them eight hours of classroom training and practice on wood poles and steel structures. Four linemen from Western’s fall protection committee instructed two six-person crews at a time. By bringing in entire crews for training rather than inviting a mixed group of linemen, Western could provide an opportunity for each crew to work together to solve problems they may encounter in the field.

During each training session, Western gave each lineman 90 minutes of classroom training, three hours of hands-on instruction on the wood poles and three hours of practice on the steel structures. The format provided consistent training and evaluation, both in the classroom and in climbing and transitioning on structures.

In the classroom, Western’s instructors reviewed the changes in the OSHA regulations and showed a video they had developed that gave a brief overview of the changes to Western’s work methods, practices and PPE brought about by the new OSHA fall protection standards. Western invited other utilities, including Pacific Gas & Electric, Tri-State Generation and Transmission, Los Angeles Department of Water & Power, and Bonneville Power Administration (BPA), out to Nevada to observe the training from Feb. 17 to March 18.

Changing PPE on Wood Poles

The hands-on portion of the training began with wood poles, which had fewer fall protection changes than steel structures. Before the OSHA ruling, crews were already using 100% fall protection while climbing wood poles. The new rules require linemen to use fall arrest devices when accessing and working on crossarms.

In its preamble, OSHA mentioned that it was inappropriate for workers to use just a body belt and skid for work positioning to access a crossarm. Up to that point, Western linemen weren’t wearing a full harness in these particular situations and, instead, were wearing traditional body belts and using a secondary point of attachment.

Going forward, the linemen must wear full-body harnesses or belts with integrated harnesses. Custom-manufactured harnesses, inspired by a BPA design, blend a traditional leather climbing belt and tower harness to reduce the amount of new equipment needed for linemen.

It took a 18 months for Western, working with vendors, to develop the Body Belt-Harness Combo, which allows a lineman not only to work on wood poles, but also to work under a helicopter and to access steel towers. Using this PPE, a lineman possesses all three types of fall protection: work restraint, fall arrest and work positioning. The Body Belt-Harness Combo, like all approved fall protection devices, is flame-retardant and passed a drop test to ensure it could withstand forces resulting from a fall.

The Body Belt-Harness Combo was just one option Western offered its linemen. Western issued linemen their choice of fall protection equipment in any combination they wanted as long as it met the requirements, including components such as the rope, webbing, aluminum carabineer, steel locks and snaps. Also, the linemen could select which version of the Body Belt-Harness Combo fit the best: leather or the synthetic material.

At each of the training sessions, the instructors brought different types of tools and materials and then laid them out for the linemen to try out in the field. When they get back to their work location, they could order the gear through Western’s blanket purchase agreement with third-party vendors.

Another reason why Western allowed its linemen to select their new fall protection gear is because the weather varies significantly from one region to the next. Western spans 15 states, and while some linemen may have to climb in icy and freezing conditions, others may work in extremely hot and humid environments.

Scaling Steel

Although most electric utilities have been able to address the fall protection for wood poles with PPE and increased training, it has been much more challenging for companies to try to work with steel towers, which were never designed or intended to be used as fall protection anchors.

Until now, steel towers were only designed to carry conductors and overhead static wires; fall protection for linemen was never a consideration. Western’s first choice is to access the structure using an aerial lift or even long-line from a helicopter, but that is not always possible. In those cases, the engineers and linemen are retrofitting existing towers with fall protection anchors, focusing first on the most frequently climbed towers. The retrofitted towers will have fall arrest rings installed under existing step bolts, which exceed the 5,000-lb anchorage strength requirement. However, retrofitting towers takes time and money, and Western needed to find alternative methods before April 1.

In turn, Western devised three primary ways to resolve the “first man up” conundrum. Once the first lineman climbs up, he or she can drop a vertical lifeline so the other crew members can climb using a mobile fall arrestor.

Some equipment used in climbing the steel structures is borrowed from the rope access realm, including the vertical lifeline and mobile fall arrestors. To ensure that their linemen know how to properly use the equipment, Western sent several linemen to become level 1 certified by the Society of Professional Rope Access Technicians. Through this training, the linemen became more familiar with the equipment and learned how to properly ascend and descend out of the towers.

Since all of the new fall protection gear adds weight to a lineman while climbing, it’s important utilities train their field crews on best practices. It can be cumbersome for linemen to climb with double pelican hooks, self-retractable lanyard, fall arrestors and other equipment, so this generation of fall protection gear still has a long way to go to be more user friendly.

Even so, this equipment helps utilities to meet their shared mission: to get their linemen home safely to their families each night. To that end, utilities like Western have strived to eradicate workplace falls from elevated work positions on transmission and distribution structures through maximum use of bucket trucks and lifts, new equipment, hands-on training and revised work practices.

David Katich ([email protected]) is the regional fall protection coordinator for Western Area Power Administration in the Desert Southwest region. He has been with the company since 2009 and has 14 years of experience as a journeyman lineman. He is a certified utility safety professional and holds a bachelor’s degree in international business from Arizona State University.

Editor’s note: Western’s fall protection coordinators' video is a available online.

Sidebar:

3 Ways to Get the First Man Up

1. Buck hook: A long pole with curved hook can reach up to 16 ft and hook around intersecting lattice members along the tower leg. The lineman is connected to the hook by a self-retractable lanyard or mobile fall arrestor and climbs up to the end of the buck hook, ties off to the tower and repositions the hook to the next height.

2. Y-lanyard: Available only for towers with engineered anchors, the lineman clips to each step bolt flange and ascends. Another similar option is to have large pelican hooks attached to the Y-lanyard, which allows a lineman to attach directly to lattice members without using step bolt flanges.

3. Lead climbing: The lineman has a belay rope that is attached to his harness and a number of draws with carbineers. The lineman ties a rope with a carabineer around the tower leg every 3 ft to 4 ft, clips in the belay rope and continues climbing. The belay rope is fed through a fall arrest device by another lineman on the ground. The device locks at any fall, and the lineman will only fall the distance to the last carabineer.

Sidebar:

Step Bolts: Not an Easy Answer

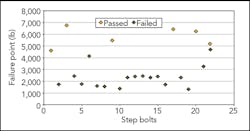

Western’s engineers have determined that regular step bolts are not suitable as fall arrest anchors at this time. Although many companies want to use them because they are in the right position for linemen to hang gear, they are not capable of supporting the fall arrest loads, according to a six-month collaborative study by BPA and Western.

In Western’s part of the study, step bolts from 23 different transmission lines were tested with a dynamic load and existing fall protection equipment in an attempt to come up with an engineered solution to use step bolts as an anchorage point. The strength of the step bolts varied from 1,336 lb to 6,763 lb. The testing showed that with existing equipment, there was no engineered fall protection system that would work for all of step bolts on these transmission lines. Further testing of step bolts was not continued. Currently, the step bolts would have to be retrofitted to be used safely.

Sidebar:

3 Types of Fall Protection

During the Nevada training session, Western’s linemen learned the ins and outs of fall protection, including the three main types and how the new OSHA ruling, which requires 100% attachment, would affect their climbing practices.

1. Fall arrest: A system that allows full access and mobility while working and also ensures the employee cannot free-fall more than 6 ft.

2. Work positioning: A body belt or body harness system that is used while climbing or working on vertical surfaces. The equipment must allow the climber to work with both hands free while leaning and also restrict any fall to no more than 2 ft.

3. Fall restraint: Devices that prevent the employee from falling any distance.