Harnessing the Power of AI for Inspections

Listen to a New Line Life Podcast Episode to Hear This Audio Story

If you want to listen to a narrated version of this feature story, which appeared in the March 2025 print issue of T&D World in the print-focused Electric Utility Operations section, listen to the audio story on the Line Life Podcast platform.

Part of our In Case You Missed It (ICYMI) series for the podcast, this audio story explores how the New York Power Authority (NYPA) is detecting anomalies and prioritizing tasks in the field through AI technology.

If you would like to share your story about how your utility is using technology in an innovative way, email Field Editor Amy Fischbach.

You can also listen to past episodes, including another audio story, "Line Monitoring: New York Style," at linelife.podbean.com. Click on "Subscribe in the top right to be notified when new episodes are available.

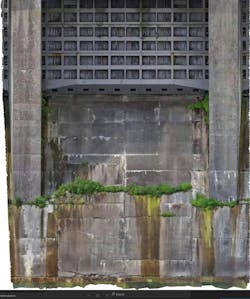

The power of technology can transform the operation and maintenance of today’s electric utilities. Case in point: New York Power Authority (NYPA) has incorporated artificial Intelligence (AI)-driven computer vision technology into its maintenance program for detection of equipment defects and anomalies using visual data captured from drones or cameras. AI-driven computer vision technology makes it possible to inspect assets without costly interruption to operations and reduces the variability in inspection quality that may be caused by human fatigue or error.

NYPA is using widely available models including Convolutional Neural Network (CNN), You Only Look Once (YOLO) and cloud-based options and adapting them through training and fine-tuning. The end result is an AI-driven computer vision model that can identify asset class and subclass like a transmission line and sort, analyze and inspect large image repositories.

“AI-driven computer vision speeds up inspections by analyzing vast numbers of images quickly to detect issues,” says Atena Darvishi, R&D director for NYPA. “Upon receiving new images from our drones, we can easily apply computer vision models that are fine-tuned for our needs. When an anomaly is detected that signals the asset requires further investigation, this rapid processing reduces the need for time-consuming manual inspection and helps prioritize maintenance efforts.”

Ricardo DaSilva, vice president of strategic operations, noted that NYPA continues to develop AI capabilities with its partners to achieve operational excellence. The Power Authority’s ISO55001-certified asset management system is focused on optimizing cost, risk and performance.

“AI-driven technologies (coupled with our robotics program) enhance situational awareness of equipment health and failure detection, which, in turn, support prioritizing operational investments and resources,” DaSilva said. “These insights offer a more robust inspection and monitoring program aligned to asset class strategies and use of predictive analytics.”

Analyzing Images

Leveraging AI-driven computer vision technology to analyze and inspect images allows for more comprehensive and accurate monitoring of assets and significantly reduces the time needed for inspections, greatly increasing overall efficiency.

“AI can also spot anomalies in patterns more efficiently, thereby allowing us to predict when and where failures are likely to occur and allowing for more targeted and timely maintenance,” Darvishi says.

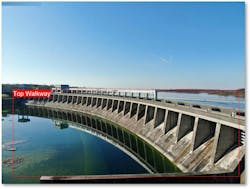

NYPA tested the models with images of assets with known anomalies/maintenance issues from its archives and open-source images available through EPRI, a non-profit energy research, development and deployment organization. Examples of anomalies/maintenance issues that were analyzed included cracks and structural damage on dams, seepage, erosion, spalling, vegetation encroachment, erosion on insulators, broken insulators and conductor damage. The models achieved high Mean Average Precision (mAP), a metric that is commonly used to measure performance and the ability to predict accurately.

Open-source or cloud-based models are readily available and cost effective. They provide flexibility, and NYPA can further train and fine-tune them for its needs. However, a vast number of these models are available, and it requires substantial time and expertise to find the best model for various types of inspections.

Speeding Up Inspections

A central platform for uploading, storage and search of drone images makes the storage and retrieval of images and inspection faster and more seamless.

AI-powered systems can process large volumes of data from cameras and sensors faster than humans, providing near real-time insights and enabling quicker decision-making. This can streamline maintenance workflows, reduce response times, and allow the field workforce to prioritize maintenance efforts. Faster inspection and decision-making can also mean safer operations for lineworkers as issues are identified and addressed before they become critical.

Integrating computer vision into operations brings additional notable benefits. AI-enabled real-time monitoring of assets reduces the need for costly routine inspections and identifies issues before they escalate. As a result, costly repairs or replacements are avoided, minimizing the need for manual labor and ensuring a more streamlined process. As R&D partners with groups across NYPA on exploring the application of AI to solve business and customer challenges, organizational and technology-based capabilities are enhanced, which leads to further application by employees throughout the organization.

Flying Drones

The utility’s robotics program began in 2016, with drones playing a critical part. NYPA uses a variety of drones from six different manufacturers to capture images of its assets across New York State. More than 100 members of the workforce have been trained as drone pilots. Recently, the FAA granted NYPA license to fly unmanned aircraft systems beyond the visual line of sight of the pilot in command in a one-mile radius in any unrestricted or Class G airspace without prior approval. The approved waiver expands NYPA’s ability to use drones to monitor and inspect its transmission, generation and canal assets throughout the state.

“Using AI-driven computer vision models to sort these images, identify assets and flag anomalies makes it easy for the field workforce to search for an image or an asset and see flags about potential issues,” Darvishi says.

The utility industry is increasingly employing AI to optimize operations, increase efficiency and improve reliability.

“AI is set to significantly improve the process of maintenance through automated inspection and provides an efficient and cost-effective way to monitor and analyze physical infrastructure, assets and equipment,” Darvishi says.

Amy Fischbach ([email protected]) is the Field Editor for T&D World magazine.

About the Author

Amy Fischbach

Electric Utilities Operations

Amy Fischbach is the Field Editor for T&D World magazine and manages the Electric Utility Operations section. She is the host of the Line Life Podcast, which celebrates the grit, courage and inspirational teamwork of the line trade. She also works on the annual Lineworker Supplement and the Vegetation Management Supplement as well as the Lineman Life and Lineman's Rodeo News enewsletters. Amy also covers events such as the Trees & Utilities conference and the International Lineman's Rodeo. She is the past president of the ASBPE Educational Foundation and ASBPE and earned her bachelor's and master's degrees in journalism from Kansas State University. She can be reached at [email protected].