Maintenance services at Klabin's pulp and paper factory in Telemaco Borba, Parana, Brazil

Today, the service sector, which after agriculture and manufacturing is the third or tertiary sector of the world economy, produces around three-quarters of the GDP of most industrialized nations – in the United States it is 76.7 percent and in the European Union it is 73.1 percent [1]. This sector comprises industries such as healthcare, transportation, finance and entertainment.

While industries in the primary and secondary sectors produce goods, those in the tertiary sector deliver services. According to Merriam-Webster, a service can be defined as a "useful labor that does not produce a tangible commodity."

Services have a few key characteristics [2]. They are:

- Intangible: They cannot be touched, are not stored or transported. Consequently, a service cannot be returned if its delivery is not satisfactory.

- Perishable: A service exists during service delivery, while the service provider appoints resources for the execution of the service. Since the service is unique (see "variable" below), this particular service disappears after delivery.

- Inseparable: The service provider and the consumer are inseparable from the service; ie, they must be in the same place at the time of the service delivery. The service may be provided automatically; therefore the servicedelivering resources may be personnel or automated technology.

- Simultaneous: Services are simultaneously delivered and consumed; ie, at the same point in time (as described in "intangible" above, they cannot be stored).

- Variable/heterogeneous: Even if a service is standardized and productized, its delivery is always a unique instance of place, time and resources involved.

Although intangible and perishable, the service industry has successfully productized services (eg, financial products) similarly to tangible products, taking into account the special characteristics of services. The well-known product marketing mix (the four Ps, or product, price, place and promotion) that is applied to goods has been expanded to seven Ps (adding people, process and physical evidence) to include the needs of the service industry.

Service being inseparable and simultaneous leads to a strong focus on the process of the service delivery, to ensure that the service delivery resources are in place in time. Defining the process also addresses the variability of services. To further control this aspect of service, people are essential. Their expertise very often defines the quality of the service.

And since service is intangible and perishable, it is challenging to prove that the service has been delivered properly as ordered. Hence it is in the interest of both the provider and the consumer to have physical evidence of the service delivery.

Service at ABB

In the example mentioned above of the service technician driving to a site with a set of tools, the service technician may have been called to repair an ABB product, but he may also have been visiting the site to perform preventive maintenance on an installation. Many of ABB's service offerings are defined around the life cycle of ABB';s product and system offerings, from installation to decommissioning.

After installation and commissioning, ABB provides consumables, spare parts or replacement parts. Over the life cycle of an installation, maintenance activities may be required, either preventive on a predefined schedule, or predictive, based on measurements and the observed behavior of the equipment. If, even with all the recommended maintenance, something breaks, an ABB service technician will quickly make the repair on-site (or for more serious failures, the technician may take the equipment off-site for repairs) or may offer replacement units instead. If later in the life cycle, a product or system is extended, upgraded or replaced with the latest technology, the decommissioned object can be recycled or disposed of.

1 Regular maintenance is carried out by ABB at the Changi Water Reclamation Plant in Singapore.

All of these services are driven by the product life cycle. Service ensures that the solution initially delivered maintains or even increases its designed performance with as few interruptions as possible ➔ 1.

In addition to product life-cycle services, there are more capabilities available within ABB that could be provided to customers as "labor that does not produce a tangible commodity." To properly design products and systems, ABB engineers need skills that can be directly applied for the customer's benefit.

Topics such as energy efficiency, health and safety, environmental compliance, and cyber security are addressed by ABB's R&D and engineering experts. Those capabilities that are normally applied to develop and produce goods can be applied to the customer's plants and processes as services.

Service technology challenges

Although people play an important role in delivering services, technology is equally important in many service industries. Air transport or healthcare services cannot be provided without the most advanced technology available. In the same vein, ABB's service delivery also depends on a number of technologies.

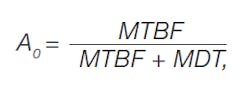

For many offerings, customers rely on ABB service to keep plant availability up. From this high-level requirement, a few conclusions can be drawn. Availability is the relationship between mean time between failures (MTBF) and mean downtime (MDT):where MDT represents the total time a plant is down, comprising planned maintenance time and unplanned repair time (ie, mean time to repair, or MTTR).

The variable most obviously influenced by service is MTTR. The more efficiently a failure is repaired, the sooner the plant can run again, and availability can thus be kept high. To achieve this, the serviceability of an installation has to be optimized throughout the service value chain.

Disassembly

In order to quickly fix a problem in an installation (ie, a product or system), it is essential that disassembly as well as reassembly can be performed expeditiously. Device development today places a lot of focus on product cost, and one way to keep it low is to reduce assembly costs. As a result, the design may not necessarily allow for easy disassembly.

A key technology for efficient service is therefore the ability to disassemble a component. Furthermore, initial assembly is done in the defined factory environment, whereas maintenance and repair is typically done on-site, where heavy equipment may not be readily available. This might require special tools or operating instructions to bring the system into a serviceable state. Thus, the easier it is to disassemble the component, the faster the system can be serviced.

Fault diagnosis

To efficiently service a component - to bring the right tools and spare parts to the site - it is essential that the fault is properly diagnosed. In complex systems, it is very often not clear what caused a failure, what needs to be fixed to bring the plant back online and what needs to be corrected to prevent future failures. Components frequently influence each other, and cause and effect can often be indistinguishable. To better diagnose a failure, there are several technologies available to support a service technician.

Diagnostic tools have become more and more sophisticated. Operational data is analyzed for typical failure patterns, or matched against modeled system behavior. For components that are automatically controlled and monitored, this functionality may be available in the control device. For more complex diagnostics, data can be collected from the device and analyzed by special tools that might be operated remotely by experts.

Other sources of information also may be helpful to quickly find the source of a fault. Databases containing statistical analyses of past product failures, eg, can give an indication. This may then be paired with recommendations from knowledge-based systems that map the plant situation with past experience.

2 The De Nittis photovoltaic plant in Foggia, Puglia, Italy is remotely monitored from the control center in Genoa.

These diagnostic systems need to be available to the service technician in the field. However, to send the person with the right expertise, carrying the appropriate tools and spare parts, it is beneficial if a system can be diagnosed remotely before someone travels to site ➔ 2.

Expert knowledge

This indicates another key technology that is required for service: the ability to make expert knowledge available wherever needed. Most obviously, this is done by bringing the expert on site. However, since there are few "top experts," it is essential that their knowledge is made more widely available by, for example, mapping their experiences in a knowledge-based system, or by allowing them to access plant data and to guide the field technician remotely.

Keeping MTBF high

These are technologies that help keep repair time to a minimum. Going back to the availability equation, there is still another variable that can be influenced. Repair time is lowest if no repair is ever necessary; ie, if MTBF is high. Of course every customer's dream installation has an infinite MTBF and does not need to be serviced at all, but apart from the impossibility of achieving this in a technical environment, the resulting cost for such a product would be too high.

Still, ABB's R&D experts aim to make products as reliable as reasonably possible. And in addition, a clever service strategy can keep MTBF high. With preventive maintenance actions, an installation is maintained in a state that prevents failures. Looking at the availability formula of the maintained plant again, this comes at a price since the maintenance time adds to the plant downtime. However, since the planned downtime of a plant can be scheduled in times of low business, and multiple maintenance actions can be executed during the same outage, the operational costs of a planned outage are much lower than a plant trip during high production.

To improve downtime due to scheduled maintenance, the same parameters used in the repair intervention are important - not only repair, but also maintenance activities need to be executed quickly and efficiently. If tools and technologies are available that allow a plant to be maintained while in full production (eg, redundant system, live maintenance), downtime can be further reduced.

Plant lifetime prediction

The most desired service technology, however, is plant lifetime prediction, which enables precise prediction of when a component will fail. Service intervals do not need to be set on the safe side, but instead maintenance could be done when optimally required. A plant is continuously monitored for patterns that predict a failure in the making. However, precise predictions will always be elusive, but will nevertheless remain the goal of service technology.

3 Service technology is used in many industries, including at ABB's high-voltage switchgear plant in Beijing, China.

The products and systems delivered by ABB are carefully engineered to work together to provide customers with the desired plant functionality. Service addresses yet another dimension of complexity in the system installed at a plant - it ensures that the functionality is provided over time. Service technology helps to track plant behavior over time, to detect malfunctions, off-specification operation, and failing devices, and to support customers in requesting service and maintenance at the optimum time. Furthermore, service technology enables technicians to efficiently maintain a plant or repair a failure to keep plant availability high ➔ 3. One of the challenges continually addressed by service technology is not only to think about how components work together, but also to consider how they are kept operational over time.

References

[1] Central Intelligence Agency (2011). The World Factbook 2011.

[2] Retrieved from http://en.wikipedia.org/wiki/Service_%28economics%29 August 24, 2012.

Christopher Ganz

ABB Group Service

Zurich, Switzerland

[email protected]