Much electrical switchgear is found out in the open, so the electrical breakdown properties of air have to be taken into account in its design. As a result, switchgear installations can take up substantial real estate. Where space is costly or limited, or where the environment is challenging, GIS is an ideal alternative. In GIS equipment, switching is done inside a gas-filled sealed vessel. The gas has much better insulation properties than air, so equipment can be made a lot smaller. Substations located underground in cities, inside hydropower dams, in high-value real-estate areas or in containers could not be realized without GIS technology.

GIS is suitable for use in harsh environments such as deserts, high-altitude locations or offshore oil platforms. Its low noise levels and low electromagnetic emissions allow operation in residential areas or in sensitive industrial plants. GIS also improves the grid's efficiency as it enables power to be transmitted at higher voltages closer to the load centers in cities.

The first GIS was installed in 1965 and used sulfur hexafluoride gas (SF6) as insulation. Today, GIS switchgear is available from 52 to 1,200 kV rated voltage [1]. Current trends and needs in GIS include:

- Less complex, more standardized designs that inherently improve reliability and ease project engineering, production, installation and maintenance. Purchase and use of GIS should become simpler, delivery times shorter and service life longer.

- Smaller dimensions that save resources, provide more convenient access to the equipment and enable installation in smaller buildings or containers.

- Digital controllers and electronic measuring equipment that provide comprehensive monitoring, supervision and control functions.

- Higher continuous current and short-circuit current ratings.

- Less use of SF6 and reduction of SF6 emissions.

ABB's new GIS products for 72.5 kV, 245 kV and 420 kV, launched in 2010, 2011 and 2012 respectively, address these trends. The entire family is built on common design principles and the family members share many common components.

Compact and efficient

The new products mark a significant advance in footprint reduction – be it in terms of dimensions or use of raw material and SF6.

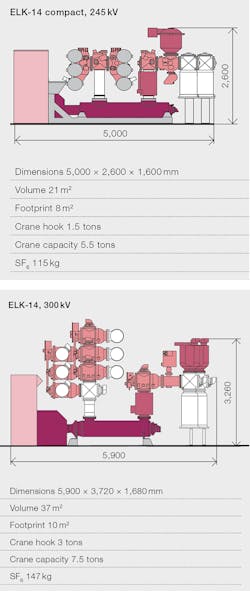

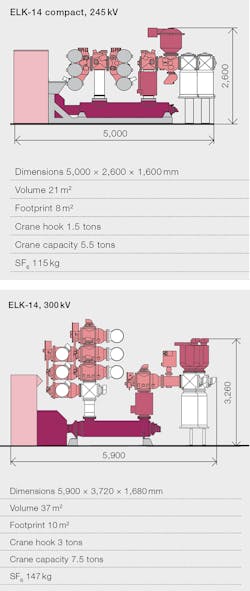

The new portfolio is based on advanced circuit breakers with small dimensions and small drives. The ELK-14 compact, 245 kV GIS features an advanced double- motion Auto-PufferTM (self-blast) circuit breaker. A single pole requires less than 900 J of stored energy to interrupt a short-circuit current of 50 kA. The ELK- 14 compact has 43 percent less volume and weighs 2 tons less than the predecessor product ➔ 1. The result is a compact bay that fits into containers that are used for shipment or even as a permanent housing.

1 ELK-14 compact, 245 kV compared with its predecessor

The ELK-3 compact, 420 kV GIS features a new, single-interrupter puffer breaker with an excellent two-cycle performance at 63 kA/60 Hz and plenty of reserve for short-line faults and other duties. The ELK-3 compact circuit breaker uses just one interrupter where two interrupters in series and a larger drive were needed in the past. The savings in dimensions and weight are significant ➔ 2.

2 ELK-3 compact, 420 kV compared with its predecessor

Low-pressure aluminum die casting and 3-D finite-element stress calculations enable the design of enclosures with complex shapes that still meet pressurized vessel standards at high safety margins. The result is "skinny" enclosures that minimize the enclosed volume and, thus, the SF6 content. A good example is the ENK GIS type for 72.5 kV rated voltage that uses a mere 27 kg SF6 per bay (for a typical double busbar bay with cable connections) – less than half that used by traditional designs. Or the ELK-14, which uses 115 kg SF6, 32 kg less than the predecessor product.

Best of both worlds

Traditional GIS often uses single-phase enclosed designs for 245 kV. Although they would reduce complexity, threephase enclosed GIS components for 245 kV are large and difficult to design. ELK-14 compact is innovative: All components are three-phase-enclosed but, instead of three-phase partition insulators, as used at 145 kV, it uses singlephase insulators. Together with skinny enclosures, ELK-14 is somewhere in between traditional single-phase and three-phase design and combines the best of the two approaches.

Simplicity

ABB's new GIS consists of a set of highly-standardized building blocks that can be configured to the specific user requirements at a very late stage of the production process. This reduces delivery time. Even at 420 kV, the GIS is equipped with integrated local control panels mounted directly on the steel support carrying the bay. Instead of wiring the bay onsite to a distant control panel, all the cabling is done at the factory in a controlled environment with automated testing facilities. Any wiring mistakes are corrected before the bay leaves the factory.

Installation time nearly halved

The new GIS designs enable complete wired bays to be shipped in containers or on flat racks. A typical 420 kV substation now requires only 44 shipping units and 53 coupling steps compared with the 80 shipping units and 74 coupling steps of the predecessor product.

On site, 420 kV bays are wheeled from the unloading platform into the building to their final destination. After leveling, coupling adjacent bays and connecting them to the substation control systems takes only a few hours. Before leaving the factory, bays are prefilled with SF6 at a transport pressure slightly above 1 bar, which significantly reduces time and effort for on-site gas handling.

In all, installation time is cut by some 40 percent.

Easy access operation

Although there is little maintenance required, all relevant parts, such as drives, view ports, gas density sensors, gas filling valves and terminal blocks are easily accessible – thus shortening maintenance or repair times.

A unique feature is that the drives and position indicators for disconnectors and grounding switches are located underneath the local control panel ➔ 3. The user can access the drives from the operator's aisle for emergency manual operation with a hand crank or to lock them with a padlock. Access ladders or scaffolding is no longer required. Besides, drives are plug-in units and they can be easily pulled out of the cabinet for inspection or maintenance.

Convenient access to viewports, gas valves and monitors is provided by platforms and catwalks. These are an integral part of the GIS and no longer require custom designs.

4 Combined ECT/EVT for 420kVDigital sensors and smart switchgear

Today's practice of measuring basic parameters using inductive current transformers (CTs) and voltage transformers (VTs) has parallels with the changeover from vinyl records to CDs: Gone was the distortion created by analog reproduction as CDs and optical links ensured low-cost, interference-free audio reproduction every time. Current and voltage measurement in substations is undergoing a similar transformation. The old problems caused by transient performance and saturation of CTs, over/under-burdening, cable length or cross section and troublesome relay input impedance are being banished by the adoption of electronic precision transducers for current (ECTs) and voltage (EVTs). These come with digital interfaces and connect as easily as a CD player to protection relays with digital inputs. Their stability, dynamic range and precision are outstanding – a single ECT provides both class 0.2 metering data and precision current data in the kiloampere range.

Consequently, most of ABB's GIS equipment is now available with compact ECTs and EVTs employing Rogowski coils and capacitive voltage transducers [2] ➔ 4. They connect to any relay with an IEC 61850-9-2-compatible digital optical interface, eg, ABB's Relion series.

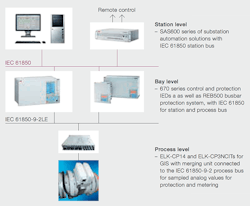

Although not yet commonly used, ECTs and EVTs, together with intelligent bay controllers, such as ABB's REC670, and protection devices, form the basis of a digital control panel. Replacing bulky hardwired controls and a sizeable binder of schematics, a digital control panel has a network interface based on IEC 61850 data models and communication protocols. The GIS bay is delivered with an electronic capability description in XML – ready to be loaded, browsed and integrated into the substation automation system ➔ 5.

As part of the new portfolio, ABB's engineers have developed a comprehensive but simple-to-operate gas monitoring system called modular switchgear monitoring (MSM) that can be added to conventional controls or digital control panels ➔ 6.

6 Gas density monitoring system, MSM On site,

MSM's main task is to detect even small leaks at rates as low as 0.5 percent per year with a set of linear prediction filters. The filters are tuned so as to distinguish leaks from natural density variations stemming from inhomogeneous temperature distributions in gas compartments. Unlike traditional gas density monitors, which would flag an alarm first when 5 to 10 percent of the SF6 had already leaked, MSM alerts the operator when as little as 1 to 2 percent of the gas has escaped.

Case study: Revsing substation

Energinet.dk owns and operates the transmission grid and the natural gas system in Denmark. The company builds intelligent infrastructure to integrate renewable energy sources and focuses on providing Denmark with green energy. Energinet.dk selected GIS technology for new 420 kV substations to reduce space consumption and visual impact.

A project currently underway is the construction of a new 400 kV connection between Kassø, near Aabenraa, and Tjele. A 400 kV double-circuit line, installed on tubular towers designed to blend into the landscape, will reinforce and renew Jutland's grid. The line will replace the approximately 45-year-old single-circuit line operating on the section today. The project received funding from the European Union’s trans-European energy networks program.

Part of the project is Revsing substation. It forms a node with other 420 kV connections along the line. Energinet.dk selected the ELK-3 compact based on a comprehensive list of selection criteria that reflect the company's demands. Decisive features were the low SF6 gas content, the compactness (resulting in a small building, crane and basement) and the short installation time.

Revsing substation will be commissioned in 2013. The new line is scheduled to commence operation in 2014.

Though established more than 40 years ago, GIS technology is still rapidly developing. It continues to serve as a key element in growing grids. The installation of GIS is becoming faster and the operation easier. Compact designs use less raw materials and SF6. Safeguarded by digital controls and monitoring functions, GIS technology is steadily improving its excellent environmental compatibility.

Hans-Dieter Schlemper

ABB Power Products, High Voltage Products

Zurich, Switzerland

[email protected]

-----------------------------------------

References

[1] Holaus, W., Stucki, F. "Breaking news: High-voltage switchgear to power China." ABB Review Special Report: Dancing with the Dragon, pp. 33 – 37. (2008).

[2] Schlemper H.-D et al., "Test and application of non-conventional multi-purpose voltage and current transducers" Cigré, Paris, 2004, paper A3-108.