Dominion's Battery Maintenance Program for Substation Operations

Battery systems typically live in the shadow of their more high-tech counterparts in Dominion’s substations. Components such as protective relays are regarded as critical to substation operations, whereas the importance of batteries is usually not emphasized. In reality, devices protecting the electric system cannot operate safely and reliably without a properly maintained and operational dc system supplied by the substation batteries. Batteries function as the backbone of the substation. They provide power to the protective relays that operate circuit breakers when a fault is detected, in addition to powering components within the circuit breakers.

A robust battery maintenance program is critical to the operation of Dominion’s substations. The North American Electric Reliability Corporation (NERC) has added several prescriptive requirements to its protection system maintenance standard to enhance the reliability of substation battery systems. Failure to comply with these regulations could not only compromise safe, reliable substation operations, but also result in harsh monetary penalties.

To comply with NERC’s requirements, utilities need to make changes to maintenance practices that have been in use for years. Many utilities are complying with the new requirements by augmenting their current preventive maintenance programs. Dominion, however, is making use of a provision in the NERC standard that allows all the battery requirements to be satisfied if continuous battery monitoring is in place.

Continuous Monitoring

Dominion initiated a joint development project with Albér to develop an innovative approach to enhance substation reliability. When the project started, Albér’s monitor was designed for a telecom installation. To be a good fit for a substation battery, however, it required some functionality enhancements:

• The ability to monitor a typical substation battery, which has 100 mA of float current

• The ability to monitor main cable connections, which are the most positive and negative leads as well as their connections that land on the dc distribution cabinet bus

• The ability to monitor electrolyte level to detect any cell that reaches the low mark

• The ability to measure battery internal resistance separate from connection resistance effectively.

Communications Key

Dominion’s electric transmission group has been busy installing battery monitors in the field and now has 180 monitors in service on 10,800 batteries. Long before the first monitor was installed, the electric transmission group developed detailed specifications for all aspects of how the monitors would perform. These specifications were developed and tested in the utility’s equipment monitoring lab. Additionally, the utility developed standards to define how data coming from the monitors would be managed, presented and used to provide the necessary alerts.

Dominion communicates with the battery monitor using its standard communications protocol already installed in the substations. The 191 analog status points for each battery monitor installation are stored in the utility’s historian (FM) through a standard substation communications protocol. This allows for trending of the data as well as notification of a point drifting from the baseline value. Dominion’s equipment monitoring lab also houses a central computer always logged on to every battery monitor. This is used to clear local memory and allow for remote access to change a setting or update firmware, for example.

A key to long-term success of the program is to communicate with the monitors using the standard protocol already installed in the substations so as to avoid having to manage numerous manufacturers’ software — from battery, transformer and circuit breaker monitors, for example — to obtain and manage the data.

The battery monitor continuously monitors all critical parameters: 191 analog status points overall voltage; all 60 cell voltages; all 60 cell internal resistance; all 59 connection resistances; inter-tier jumper resistance; room temperature; top and bottom cell temperatures; charging current; discharge current; main cable and bus connections resistance; electrolyte level; battery open condition; and loss of communications.

Features and Benefits

Installing battery monitoring enables the utility to better determine the operating condition of the dc supply system, which is critical to the safe and reliable operation of the electric system. It also ensures the utility meets or exceeds NERC Standard PRC-005-2 requirements. Monitoring allows for remote access to evaluate the condition of the dc system during storms, earthquakes or black starts. When restoring a substation, the dc system must be capable of providing power for the critical equipment to operate back to service. This ensures equipment, utility personnel and the public are protected should a component fail during re-energization.

Monitoring provides early detection of potential issues when monitored values begin to drift from a benchmark. In turn, this allows for a planned approach to address operating problems. Overall, monitoring greatly enhances the reliability of the substation dc system.

The automated review of the test results, with notification when a threshold is breached, is a significant feature of the automated monitoring system. It also provides consistent measurement of all parameters. This system increases cost savings by reducing maintenance and manpower requirements while increasing the lifespan of the batteries.

Without a monitor, cell voltages and the internal/connection resistance test may be performed manually every 18 months. With a monitor, cell voltages are checked automatically every 2 seconds, and the internal/connection test is performed automatically every 14 days.

Monitor Maintenance

Dominion applies the same process it uses to execute the major substation inspection to perform its battery monitor maintenance. Field technicians scan the barcode on the monitor using a handheld computer, producing digital questions that are uploaded into the plant maintenance database system. If the answers to any questions are outside the allowed specifications, a corrective maintenance work order is produced automatically. The cycle for maintenance is a five-year interval and takes four man-hours to complete.

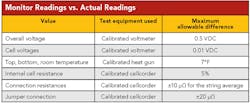

To ensure the monitor is correctly measuring readings from the battery, Dominion compares certain monitor output values with actual readings taken from the battery. The difference between the monitor’s output and the actual reading must not exceed predefined values supplied by the monitor manufacturer.

Dominion also verifies the monitor loss of the power alarm and loss of the communications alarm, as well as confirms correct monitor readings are being stored in the data historian. The notification process is verified by forcing abnormal conditions in the field and ensuring proper communications are sent out as a result. All monitor-associated fuses also are replaced during maintenance.

Keys for Success

The success of Dominion’s battery monitor program is based on three key attributes:

• Display the information. A web viewer, or dashboard, provides a view of everything associated with the dc system at any given battery monitor installation.

• Notify when a point breaches a threshold. The FM point monitor process is available in SharePoint.

• Manage the alarm. The process was created in SharePoint.

These key attributes are applied to monitors for all substation equipment. A dedicated staff and resources combined with Dominion’s commitment to reliability have allowed for the program to be a success.

Michael W. Powell ([email protected]) is a manager of electric transmission field operations with Dominion Virginia Power. His 32-year career at Dominion has focused primarily on substation equipment. He is currently responsible for Dominion’s nuclear switchyard program, electric transmission maintenance compliance program, substation equipment monitoring program and substation plant maintenance management program.

Companies mentioned:

Albér | www.alber.com

Dominion Virginia Power | www.dom.com

North American Electric Reliability Corp. | www.nerc.com

Sidebar: Installing a Monitor

Dominion has developed a standard process for installing its battery monitors. The first step is to perform an initial site visit to determine where to locate the monitor (wall or relay rack mount) and develop a list of materials required for installation. The station prints are then updated to reflect the battery monitor installation in the chosen location.

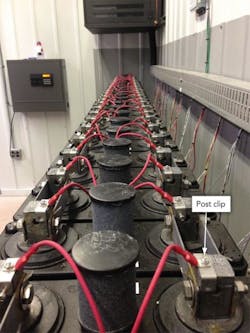

During the second site visit, a battery trailer is paralleled with the substation battery so that post clips and load leads can be installed. The third visit is devoted to installing the battery monitor cabinet or relay panel and running the dc power, alarm wires and local area network wire. At the fourth site visit, a certified Albér installer installs the battery monitor and verifies the monitor wiring.

The next step is for Dominion’s monitor group to request an IP address, submit alarm set points, and build the web viewer and dashboard intranet pages.

During the final site visit, the unit is commissioned by a certified commissioning agent and the commissioning check sheet is completed.

The final steps in the process are to complete the digital install/remove sheet that will enter the monitor into the plant maintenance system and implement the digital maintenance questions associated with the monitor. At that point, the monitor is declared to be in service and the maintenance program for the battery is adjusted to account for the monitor being installed.