Mitteldeutsche Netzgesellschaft Strom mbH oversees a 74,000-km (45,984-mile) distribution network that comprises 6000 km (3728 miles) operating at high-voltage, 24,000 km (14,913 miles) at medium-voltage, and 44,000 km (27,340 miles) of low-voltage cables and overhead conductors. The utility supplies around 2.3 million people in eastern Germany in a 28,000-sq-km (10,811-sq-mile) area. The medium-voltage network level is particularly vulnerable, having a significant failure rate that affects the supply to numerous private and commercial customers. Although the failure rate is considered reasonable for the age of the underground cables, there is a need to reduce the failure rate to satisfy the demands of customers and lower the revenue expenditure on fault repairs.

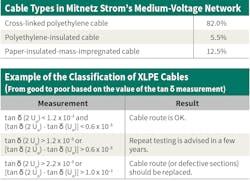

A member company of the enviaM Group, Mitteldeutsche Netzgesellschaft Strom mbH (Mitnetz Strom) services the medium-voltage network, which contains cable systems of various ages ranging from paper-insulated mass-impregnated cables, to polyethylene (PE)-insulated cables to cross-linked polyethylene (XLPE)-insulated cables. The latter now comprises 80% of the cables in service on medium-voltage circuits.

Initially, Mitnetz Strom thought condition-based maintenance should replace event-driven maintenance to reduce the network maintenance costs associated with fault-finding and repair. Also, a lower failure rate means a lower average system interruption duration index (ASIDI). This value of the average cumulative duration of power supply interruptions must be reported to the Federal Network Agency by all German medium-voltage network operators. The ASIDI, together with other quality-of-supply indices, is important as it governs the level of grid charges permitted by the Federal Network Agency.

Condition-Based Maintenance

Prior to 2011, maintenance of the underground cable network was performed on an event-oriented basis with faulty cables being repaired and those with more than three faults in five years being replaced. However, a reduction in the failure rate for a given budget was not achievable using the available fault-finding technologies. In 2011, when the number of cable failures exceeded the total in previous years, Mitnetz Strom decided to invest in cable diagnostics.

The utility thought the diagnostic evaluation of the important cable circuits would provide information on the condition of the cable insulation and accessories, permitting predictive maintenance on 16,000 km (9942 miles) of underground medium-voltage cable. The utility’s investment decision assumed the average duration of failures because of cable faults could be reduced by up to 40%. Therefore, in 2012, Mitnetz Strom purchased its first cable test van equipped with the PHG 70 TD/PD, a compact very low frequency (VLF) cable testing and diagnostics system from Baur.

Diagnostics Procedures

Application of VLF technology provides measurement of the dissipation factor and partial discharges. The low measuring frequency (for example, 0.1 Hz) reduces the reactive power requirement of the test equipment. This means VLF measurement systems can be compact and portable. Also in favor of VLF technology is the dissipation factor measurement, which is very precise using a pure sinusoidal waveform that permits accurate interpretation of the measurement results.

The VLF tan δ measurement, or dissipation factor measurement, is a nondestructive method for determining the condition of cable insulation. The measurement establishes the ratio of active-to-reactive cable power. This essentially is the aging of cable insulation. With the dissipation factor measurement, the aging of XLPE-insulated cables can be established from the water trees that spread like small trees at fault positions in the insulation. Ultimately, they become electrical trees at which local discharges occur that directly cause a breakdown. Therefore, early recognition of water trees is essential for anticipatory, condition-based maintenance.

Measurement of tan δ at different voltages is necessary to identify meaningful values of tan δ. Measurements are normally performed at 0.5 x Uo, 1 x Uo, 1.5 x Uo and 2 x Uo, (where Uo donates line voltage to ground). In the case of a new cable, tan δ would be nearly zero. If the recorded values are plotted against voltage, a characteristic curve is produced that confirms the dissipation factor rises sharply with voltage for aged cables. In addition to the absolute value of tan δ, the scatter of the measurement results also merit attention. If measurements performed one after the other under otherwise-identical conditions produce highly varying results, this gives rise to a high standard deviation, which is an indicator of partial discharges in the cable route.

The tan δ method also can be used for evaluating the condition of mixed cable routes (for example, PE/XLPE and paper-insulated mass-impregnated cables), but it is more difficult to determine limit values for good or poor. Knowledge of the cable route and, where applicable, its repair history also can be important for the evaluation of the dissipation factor.

Partial-Discharge Testing

Small short circuits or breakdowns are the result of local partial discharges. By measuring the partial-discharge activity, fault locations or cavities in the cable can be detected (for example, electrical trees in XLPE cables or damage to paper-insulated mass-impregnated cables due to drying out).

Partial-discharge testing also is useful for checking joints and cable terminations in new cable routes as partial-discharge testing enables the results to be assigned to these circuit accessories and joints relatively reliably. If no precise location can be made, pinpointing can be performed using a Baur partial-discharge indicator.

For newly installed cables, partial-discharge testing generally is nondestructive and suitable for all types of cable. However, measurement engineers need to know the composition of the cable circuit (for example, type of cable and accessories) to interpret the results, as they vary significantly depending on the material and component.

Diagnostics System

Since Mitnetz Strom introduced the first Baur cable testing and diagnostics system, diagnostic measurements have been undertaken regularly on selected cable circuits. Many factors influence the selection of the circuits to be tested, the age of the cable route, defect and condition data, the significance of the network section in the medium-voltage network and the circuit load flow. Furthermore, priority is given to cable routes near planned construction works by other utilities, so any repairs or cable replacements can be performed simultaneously.

This prioritization means, for construction-related reasons, it is becoming increasingly common that a disproportionate number of the circuits to be diagnosed comprise different cable designs. After more than three years of experience, many already measured circuits are selected for a measurement again. Once the cable route to be tested has been selected, it is incorporated into the job schedule with a lead time of two weeks, giving sufficient time to plan an outage.

Data On-Site

The cable measurement engineer who receives the job data in advance by a workforce management system (WMS) can access the cable data and line route on a tablet through the geographical information system (GIS). For new medium-voltage networks, partial-discharge testing can confirm whether the joints and terminations have been installed correctly. Thus, any installation faults can be identified and rectified early, rather than showing up years later in the form of a cable fault. Cable sheath testing also is performed on plastic-insulated cables. On open switchgear, partial-discharge testing also is performed with a hand scanner to detect dangerous partial discharges.

The measurements are conducted and controlled from the cable test van, with the on-site engineer able to specify preconfigured processes (or the processes programmed by the utility). During testing, the measured values are monitored continuously so the engineer can intervene at any time, such as in the event of extreme values. The evaluation then is performed directly on-site so the cable circuit can be restored to service quickly or any required rectification measures can be programmed.

All results then are transferred by USB drive to Mitnetz Strom’s data server, so a convenient desk-based evaluation can be executed. This enables rapid access to comparative data from other cable routes or values from previous measurements on the same cable. After the evaluation, the diagnostic protocol generated is linked to other systems and appropriate measures initiated.

Test Results

By the end of 2016, just four years after Mitnetz Strom introduced diagnostic testing, a total length of 2500 km (1554 miles) having around six joints/km (10 joints/mile) had been tested. On 20% of the circuits tested, the tan δ or partial-discharge test showed there was an urgent need for action to rectify potential defects within a few weeks. An additional 30% of the cables tested were noncritical; for the remaining 50%, a new measurement was recommended within one to three years.

Because of diagnostic testing, maintenance measures are managed significantly better and revenue expenditure invested more wisely now that a wealth of experience has been established. However, even now, a few failures occur in cables that have been subjected to diagnostic testing but were not repaired quickly enough. To prevent this in the future, Mitnetz Strom has tightened up the classification of its cables and thus can tackle potential weak points earlier.

Despite the learning curve operators of cable diagnostic equipment face initially, the failure rate of medium-voltage cables has improved rapidly. In 2012, when the first measurements were performed, there were fewer failures than in the previous year. In 2015-2016, the number of technical failures in medium-voltage cables was just more than 60% of the failures that occurred in 2011.

Mitnetz Strom is now a specialist in cable diagnostics, followed by other network operators who are increasingly applying diagnostic measurement technologies to benefit from this cable network-specific development.

Economic Benefits

Mitnetz Strom evaluated cable diagnostics in 2014 to understand the economic benefit. The results showed the additional cost of investments and measurement time paid for itself, as maintenance can be performed in a targeted fashion and at reasonable cost. For example, costly technical failures of previously damaged equipment can be detected in advance and avoided by preventive replacement.

In the medium term, the reduction of the ASIDI value also contributes to the economic viability of this maintenance procedure. For Mitnetz Strom, even a fraction of the theoretical reduction potential, namely, 40% fewer cable failures, represents a saving of more than 1 million euros.

Because of the positive technical and economic experiences, diagnostics are now firmly embedded into everyday operations. Nine cable test vans are now equipped with VLF diagnostic technology at Mitnetz Strom, and no further cable test vans will be purchased unless they are equipped with diagnostic tools designed for comprehensive testing of underground cable circuits.

By using the technical equipment currently available, the Mitnetz Strom team now can measure approximately 800 cable circuits annually. And in view of the diagnostic options and past success rate, the goal of reducing technical failures by 40% is now within reach. ♦

Thomas Gurski joined Mitteldeutsche Netzgesellschaft Strom mbH in 2010 after earning an electrical engineering degree from the University of Applied Science in Mittweida, Germany. Gurski now is responsible for measurement technology in the operations department.

Axel Sieler is a measurement engineer in the special service and measuring department at Mitteldeutsche Netzgesellschaft Strom mbH.