Distribution utilities in New Zealand have followed the global IEC 61850 standards and developments since 2005. Of the 29 distribution network operators (DNOs) in the country — each with varying ownership structures — many of the larger DNOs have been involved with this substation automation development. Vector Ltd., the largest DNO in New Zealand, supplies all the electricity customers in the greater Auckland region and has been using IEC 61850 for the past decade.

Most of Vector’s primary substations are equipped with IEC 61850-compliant intelligent electronic devices (IEDs). Vector has 105 primary substations fully or partially equipped with compliant IEDs, together with automation and interlocking schemes using generic object-oriented substation event (GOOSE) as applied to substation automation systems. Vector’s fleet comprises more than 2500 IEC 61850 IEDs of different generations.

Distribution utilities such as Vector face increasing challenges in managing their device-protection settings because of changes occurring in the distribution network. In Auckland, an ever-increasing number of new subdivisions are being developed, and customers are requiring new high-voltage supplies that require network reconfiguration. Additionally, customer demand for the installation of large-scale embedded generation is increasing, which requires revisiting protection settings and changes to automation schemes.

Cost-Effective Replacements

Vector already uses modern-type voltage regulator relays (VRRs) in its transformer management system (TMS) application, which is fully integrated with the protection schemes. These normally are deployed with new high-/medium-voltage power transformers or installed during major zone substation asset replacement projects. This type of TMS application is already installed on approximately 40% of the network’s power transformers. The remaining 60% of transformers come from a wide variety of manufacturers and many of them are no longer manufactured, mainly because of the age of the equipment.

Vector requires a simple and cost-effective solution to enable quick replacement of end-of-life or failed VRRs on high-/medium-voltage transformers. The main requirement is compliance with IEC 61850, which includes features such as GOOSE messaging, interoperability with other manufacturers, and data that can be gathered and used for further analysis. Key end-use applications include supervisory control and data acquisition (SCADA), condition-based maintenance and performance data to enable optimum use of primary assets.

Following some research and high-level product evaluation, the SEL-2414 transformer monitoring unit from Schweitzer Engineering Laboratories (SEL) appeared to offer an economical solution. Subsequently, Vector upgraded it to include transformer management logic, which could be used with its TMS application. As Vector already used many of SEL’s products, its engineers and contractors in the field were familiar with the configuration tools as well as the design and performance of the products. From a financial perspective, Vector compared the SEL-2414 with the traditional transformer monitoring scheme it previously installed on new high-/medium-voltage transformers, and the cost savings were in the region of 30% to 50% less, depending on the site configuration.

Vector’s Solution

Vector selected the SEL-2414 transformer monitor because it is designed to withstand harsh physical and electrical environments, and it is built and tested to meet mission-critical IEEE and IEC protective relay standards. It provides a great combination of monitoring, control and communications in a compact package, and it can be used in a stand-alone mode or for the distributed monitoring and control of transformers.

The SEL-2414 can be configured with various input/output (I/O) options so it meets each site-specific requirement, such as detecting oil levels or sudden internal pressure changes by alerting alarm systems or control functions. It is fully IEC 61850 compliant and provides dual Ethernet ports for redundancy.

Design Application

Application of the transformer monitor as a voltage regulator for the parallel operation of primary transformers was enabled through the development of IEC 61850 GOOSE messaging. It is no longer necessary to use a proprietary peer-to-peer protocol to transfer analog and digital information.

Information from any substation equipment connected to the station bus can be transferred between devices. Scheme design using native relay logic in conjunction with GOOSE messaging facilitated the application of distributed protection and control schemes, which could not be realized previously. Using the SELogic control equations means the code is open. The settings can be modified easily, if necessary, during bench testing or commissioning to alter alarms for operational requirements. The inherent flexibility enables end users to create the scheme they need rather than accept the vendor’s solution.

A simple direct-current power system was written to simulate transformers, circuit breakers, tap-change position transducers and other substation equipment using IEC 61131 logic. This was connected to the SEL-2414 transformer monitoring unit through GOOSE messaging to test, develop and prove the logic before the remote analogs and virtual bits were changed to their in-service signals, whether they are measured analogs, digital inputs, or analog or digital GOOSE messages.

The transformer management logic supports the master-follower scheme as well as circulating current, so the main application will be master-follower. This typical application is used at a primary substation equipped with two high-/medium-voltage transformers, with an high-voltage switchboard that includes a bus-section circuit breaker. The master-follower scheme was chosen because the impedance difference between the two transformers is usually not more than 10%, and the two existing transformers have similar ratings and capacity. The existing scheme is master-follower, which did not cause any issues.

The SEL-2414 is integrated fully with the existing IEC 61850 communications scheme, with most sites having interoperability between Siemens and SEL products. Using GOOSE between the two VRR relays eliminates the need for master-follower wiring. To be flexible for future applications, it was tested by the on-site commissioning teams to ensure the voltage can be transmitted by GOOSE messaging, in case the device is installed at a different location later.

GOOSE messaging is used to publish the statuses of incoming high-voltage circuit breakers and the bus-section circuit breaker, if applicable. This reduces the amount of wiring and saves on physical I/Os on the SEL-2414. The new devices are installed in the same place as the old VRRs, which also saves on the cost of installing new panels and additional wiring. The voltage indications in this case are still in place and used as direct inputs.

Winding temperature monitoring also forms part of this application, with the recorded temperature being used to calculate the hot-spot temperature in accordance with IEEE 57.91,1995. The top oil temperature is also measured and recorded. Transformer thermal protection (winding temperature) is transmitted through GOOSE messaging from the SEL-2414 to the corresponding high-voltage incoming feeder management relay. Communication to SCADA is through the management message specification (MMS) used as part of IEC 61850.

Project to Date

After the design specification and IED settings were completed, contractors completed on-site commissioning at Vector’s Belmont Zone substation in May 2017 for a pilot project. Following research and high-level evaluation, design consultants were confident the installation of the SEL-2414 would be successful. Using this example, it was possible to simulate all basic functionality; therefore, the inclusion of Siemens’ Feeder Management Relay was introduced to simulate the GOOSE messaging for breaker status and voltage values. It was hardwired on this project.

This resulted in a decision to proceed with a trial installation at an existing primary substation equipped with an outdated VRR control system. Developed with one of Vector’s design consultants, the new design concept is a generic solution that will be suitable for installation on approximately 90% of Vector’s existing high-/medium-voltage transformers in primary substations. If successful, the next step will be to create a standard design with standard settings for all future replacement projects. This will take into account learnings from the pilot project.

Future Development

The adoption of IEC 61850 is growing and expanding constantly into the upcoming areas of the smart grid, and utilities are becoming increasingly data driven to ensure optimization of network investment. The data derived from the now-outdated VRR schemes was mainly of interest to the SCADA system to operate the network. Currently, data generated by IEDs can be used for more applications, including full integration into the corporate world. Vector is actively looking at making the most out of the IEC 61850 features to run the network as efficiently as possible. Currently, there are probably more questions than answers, but a roadmap is in development to look at data integration for applications like condition-based maintenance and asset thermal ratings.

The VRR relay replacement application is positive step forward in IEC 61850 applications at Vector. At present, there is no overarching tool for IEC 61850 that can be used for IED configuration, which is a challenge. The idea behind IEC 61850 of using the top-down approach, whereby the IED configuration is just a link in the system, still requires further development and buy-in from leading manufacturers. Currently, only vendor-specific tools can be used.

Overall, it is pleasing to recognize the continuous development of IEC 61850 and the growing number of products on the market. The immediate benefits of using this technology include savings in wiring on-site and less maintenance, as GOOSE is a self-monitoring technology. However, IEC 61850 has more to deliver because it uses a proper data model that can be leveraged in other applications in the corporate world, as asset management systems are just one application. Vector is monitoring all developments closely and evaluating the advantages for its application and network needs. ♦

Ralf Huebner is currently manager of protection and SCADA at Vector Ltd., New Zealand. Huebner has 13 years of engineering experience in utilities, having worked in Germany and New Zealand on SCADA systems, substation automation and communications systems. He has a degree in engineering.

Nirmal-Kumar Nair is an associate professor at the University of Auckland, with previous professional and research experience in the U.S. and India. His current focus is integration of distributed/renewable resources, with an emphasis in protection (IEC 61850 and small power system islanding), economics (demand-side management and ancillary services) and innovation (storage, large-scale electric vehicles and photovoltaic integration). He serves in various capacities for the IEEE Power & Energy Society, as secretary for CIGRE New Zealand and as a representative on CIGRE Study Committee B5 Protection & Automation.

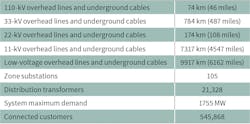

Sidebar: Vector Limited

New Zealand’s largest distributor of electricity and gas is located in the Auckland region on the North Island. The key system statistics for the year ended March 31, 2017, are included below:

Check out the February 2018 issue for more articles, news and commentary.