Two components are essential to the transmission and distribution of electricity over any distance: a conductor and an insulator. The conductor carries the power, voltage and current customers need to light and cool their buildings and to run their equipment. The insulation surrounding the conductor ensures the power does not escape and lead to arcing, fire, explosion, contact voltage or endanger the public and utility crews.

However, insulation also can conceal problems until it is too late. A compromised crimp connection or the damaged strands of a conductor — hidden by insulation — can evolve to compromise insulation, creating the potential for an event. These hidden conditions are most prevalent in the low-voltage distribution system, where the miles of cable and numbers of connections are the greatest. Con Edison — serving New York City and Westchester County, New York, U.S. — tries to combat these hidden conditions through a visual inspection program, which began more than a decade ago.

Now in its third cycle of visual inspections, Con Edison has been successful in helping its field and engineering forces locate and prioritize many types of defects for repair. These inspections, along with aggressive mobile and manual scans, have helped to reduce instances of contact voltage on the utility’s system. To achieve the next level of improvements to public safety, particularly around manhole events, the utility has introduced an infrared scanning program to complement and enhance its visual inspection program. The utility is using infrared technology and current measurement to detect these visually hidden defect conditions before they create a hazard or affect service to customers.

From Project to Program

Con Edison’s distribution engineering staff worked with the utility’s research and development team to determine whether infrared technology could help to identify hidden conditions on cables and connections. Before committing to this technology in a full-blown program, the utility ran a pilot project.

Con Edison selected 400 structures in Manhattan for enhanced inspections based on attributes such as cable type and history. During the pilot, the utility looked to gather as much information as possible by taking high-resolution infrared photos, high-definition photos, videos and current readings at each structure. Distribution engineering staff analyzed the initial data, scheduled follow-up visits to confirm suspect findings and established criteria to govern whether a condition should be considered a defect in need of repair. Because of the research project’s success in finding defects, Con Edison transformed the pilot project into a program.

Analysis and Mitigation

In 2015, targeted inspection crews started incorporating tasks from the pilot project into their inspection process to accomplish infrared scanning and current measurement. Now when crews arrive at a structure, they take multiple infrared and visible images to capture all the cables in the structure. The crews also use ammeters to obtain measurements on both mains and services. Before crews leave a structure, they make a panoramic video to create a record of how the structure looked when they were done. All the images and current readings gathered by crews go to the distribution engineering staff for further analysis and repairs are scheduled as appropriate.

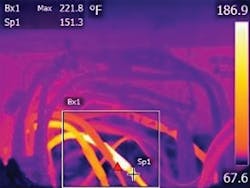

Analysis usually begins by reviewing the thermal images to understand the temperature profile of the cables in each structure. A hot spot is the clearest indicator of a hidden secondary system defect that infrared technology can detect. A hot spot is an area of a cable or a cable connection that is hotter than the rest of the cable. Because the thermal images detect surface temperature, Con Edison prioritizes repairs to cables and connections with hot-spot temperatures above the cable’s rating.

In one instance, Con Edison measured 302˚F (150˚C) at one point on the surface of a cable, but then it measured only 178˚F (81˚C) about 1 ft (305 mm) away on the same cable. The distribution engineering team recognized both the high spot temperature and the difference between the two temperatures as clear indicators of a connection problem, and thus the need for high-priority repair. When an area of cable is hotter than its rating, it has the potential to burn the insulation and give off combustible gases.

The presence of a hot spot hotter than the cable’s rating is not the only condition that can indicate the need for a repair. Even a cable with a temperature below the cable rating can be flagged for review and repair if the temperature is significantly out of proportion to the amperage. For instance, if the temperature of a cable section is slightly below the rating, such as 10% below, but the cable is operating at a fraction of its load rating, further investigation is performed. With anticipated changes in load, such as on hot summer days, the hot-spot temperature could easily increase beyond the cable rating.

Actions to Take

When a hot spot is found, crews mitigate the issue. The temperature profile can confirm the problem’s root cause and indicate a crew should remake the connection, as opposed to just reinsulating. After Con Edison crews cut out and remove a defect, the cable or connection specimen removed goes to Con Edison’s Cable & Splice Center for Excellence in the Bronx for a forensic investigation.

During the analysis, Con Edison’s experts strip away the cable insulation to analyze the conductor and connection. The Cable & Splice Center prepares a report on the root cause and shares it with the team. The report and analysis help to provide crews with a better understanding of the problems to look for and practices to avoid to prevent a future occurrence.

The Cable & Splice Center has confirmed hot spots occur predominantly at connection points. As the weakest points on the system, these connection points are vulnerable to hot spots because environmental contaminants, such as road salt, can enter the insulation. The salty water oxidizes the cable and connection point, increasing its resistance. The increased resistance of the damaged connection points leads to a buildup of heat. The thermal imaging camera can detect the difference in heat easily at this connection point.

The initial goal of the program was to find these hot-spot conditions; however, after implementing the program, Con Edison found the thermal imaging cameras could detect other system conditions. The images and data help to locate unbalanced or overloaded cable conditions when one or more phases are significantly hotter than the others. A loading condition is different from a hot-spot condition in that the temperature is consistent along the length of the cable. With a hot spot, the infrared images display a section of cable or connection that is hotter than the rest of that same cable. To verify a loading issue, crews take additional current readings of the subject and adjoining cables to determine what, if any, action is necessary.

While a hot-spot condition is a reliable indicator of a defective connection or section, loading should not be mistaken as a defect on the connection or cable. When a loading condition is found, crews need to follow up in a different way as compared to a hot-spot condition. The loading condition requires the utility to plan work in and around the structure to reinforce and redistribute load. The work could range from the replacement of limiters to the addition or replacement of cable to support the higher loads.

The thermal imaging program has found many defects that might have gone unnoticed otherwise, until an event occurred. More than a year into the program, Con Edison continues to expand the use of infrared technology and associated data analytics to further gains in public and employee safety.

Future Developments

In both the research and program phases, Con Edison has explored a variety of infrared camera designs in search of the models that would provide the best resolution, focus, durability, post-image processing capability and ease of use. The utility is currently using and testing cameras from FLIR Systems and Fluke Corp.

Con Edison is also working with Columbia University to develop tools to automate the analysis of the information inspection crews gather from hundreds of structures each week. Additional analytic tools are in development to advance condition detection and asset management through new image-processing techniques.

Action or No Action

What happens if the utility takes no action? An unaddressed hot spot has the potential to burn off the cable’s insulation. The compromised insulation may lead to arcing and buildup of combustible gases in the structure or a bolted fault with immediate energy release. In either case, combustible gases or a fault can lead to a manhole event or the generation of carbon monoxide, a poisonous gas that can back up into nearby buildings through ducts. Thermal imaging cameras, in combination with existing current clamp tools, enable crews to find and mitigate the root cause of a problem proactively.

Because of the infrared scanning program’s success in finding and mitigating nearly 100 hot spots on the system, Con Edison is continuing to develop and expand the tools, processes and training. Infrared imaging is making Con Edison’s underground distribution system safer for employees and the public, and more reliable for customers.

Colleen Murach is a technical associate with Con Edison. She holds a BSEE degree from Manhattan College and works in the distribution engineering department at Con Edison of New York, continuing her work researching, developing and implementing public safety projects and programs.