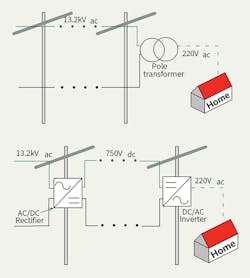

Low-voltage direct-current distribution is being considered globally as a replacement for alternating-current distribution to provide a stable power supply for digital consumer electronics devices and improve network efficiency following the interconnection of renewable energy sources. The application of direct-current (dc) distribution increases rapidly when loads and other sources of energy are pure dc.

In 2016, the world’s renewable energy market reached 125 GW, up 14% from 2015. And, because of the current climate-change regime, the world’s renewable energy market is expected to continue increasing at this high growth rate.

To satisfy the market demand for increased interconnection of renewable energy sources and the emergence of dc customers, Korea Electric Power Corp. (KEPCO) has been developing low-voltage (LV) dc distribution and operation technologies since 2009. KEPCO has constructed the world’s largest dc distribution demonstration test site and recently implemented two major LV dc projects: an actual system application demonstration project and a dc island construction project.

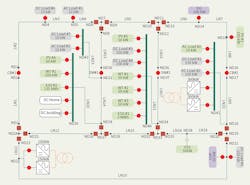

DC Distribution Test Center

The dc distribution demonstration test site is located at KEPCO’s Gochang Power Test Center in South Korea. The site is the largest in the world, with 6 km (3.73 mile) of overhead line and underground cables. The center is equipped with a 500-kW ac-dc power converter, a 2-MW energy storage system (ESS), 250-kW wind turbines, 250-kW photovoltaics (PVs), 50-kW vehicle to grid (V2G), a 100-kW diesel generator, 100-kW cogeneration facilities, 600-kW artificial load, dc home appliances (for example, refrigerators, computers and TVs), high-speed dc circuit breakers and operating systems.

The performance of this equipment and the system operation technologies are tested and verified before they are applied to actual systems through a dc distribution line connected with renewable energy sources. In addition, safety technologies for dc distribution are being developed by using line fault simulation devices and grounding safety verification facilities.

KEPCO currently has two demonstration projects, an LV dc overhead line in the metropolitan city of Gwangju, South Korea, and an LV dc distribution network on the South Korean island of Geochado in the South Sea.

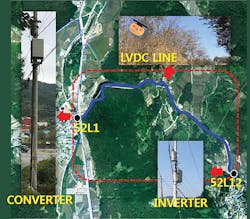

LV DC Overhead Line

The object of KEPCO’s LV dc overhead line distribution project is to verify that overhead line faults and maintenance costs will be reduced when replacing a high-voltage (HV) alternating-current (ac) overhead line with an LV overhead line in a mountainous area where maintenance is difficult.

The selected LV dc distribution overhead line is an existing 22.9-kV circuit from Mangwol, South Korea, to Cheongokjji, South Korea, where existing overhead conductors have been replaced by aerial bunched conductors (ABC) because of the potential for line faults caused by tree contact. The LV dc line has been used to compensate for voltage drop on a long distribution line that supplies a total load of 27 kW, consisting of a mix of agricultural, residential and street lighting loads. To overcome electrolytic corrosion, the dc line is ungrounded, so all electrically conductive equipment is earthed independently.

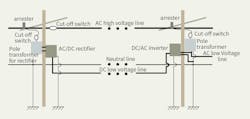

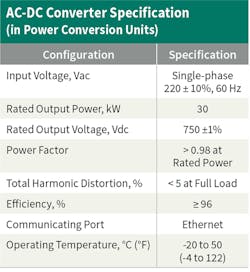

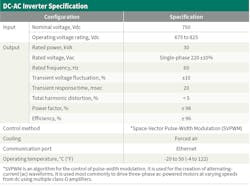

The ±750V ungrounded-type overhead line consists of a 75-sq-mm (0.17-sq-inch) cable, a 30-kW ac-dc power converter, a 30-kW dc-ac power converter and an operating system. The ac-dc converter input group consists of a single-phase 22.9-kV, 220-V pole-mounted ac transformer. In addition, the LV dc line has a line cutoff switch (COS), load pole-mounted transformer and ac switchgear installed for protection in the event of a fault on the LV dc distribution line.

Power Conversion Units

The power conversion units, namely the ac-dc converter and dc-ac inverter units, are mounted on the same pole as the transformers. To improve their efficiency, all switching elements are constructed of silicon carbide. To protect the units from surge voltages and lightning, surge-protection devices are installed on the input and output elements. In addition, the units are protected from overvoltage, LV, overcurrent and overheating; and the software features a fault-detection function. In the event of a blackout, an automatic restoration function is supplied by batteries with a two-hour rating.

Prior to the installation of the converter and inverter on the LV dc line, the operational performance of these units was tested at the LV dc demonstration site at the Gochang Power Test Center. Because of the approximate 8-km (5-mile) distance between the LV dc overhead line and remote monitoring system, additional communication lines had to be installed.

Overhead Line Construction

Site acceptance and long-term operational tests were undertaken during a two-month period at the Gochang Power Test Center. Construction of the actual LV dc overhead line took three days. Most of the time was spent installing the communication link between the LV dc overhead line and remote monitoring system.

Construction of the LV dc overhead line was completed in August 2016 and the line currently operates as intended. KEPCO continues to record operational data, which will provide the basis for initiating any minor network improvements.

Geochado Demonstration Project

Despite the increase in renewable energy sources, diesel generators remain in service, supplying a high proportion of the electricity demand on island distribution networks. In South Korea, there are 63 islands that use diesel generators as their main source of electricity generation. To reduce dependence on diesel generation, it is necessary to consider expansion of microgrid renewable energy systems, including ESS and energy management systems (EMSs) coupled with demand-response schemes.

Renewable energy in the form of ESS and PVs are dc systems that, if connected to a dc network, would overcome the frequency and harmonic problems experienced when connected to an ac network. To take advantage of the benefits of a dc network and the increasing use of ESS

as well as PVs, KEPCO launched a project to demonstrate the advantages of a LV dc network on the island of Geochado.

Geochado actually is composed of two islands, Seogeochado and Donggeochado; the islands are physically separated but share an electricity supply system by cables installed between the islands. Seogeochado was selected for the LV dc demonstration site, as Donggeochado is being used for another KEPCO project. Three diesel generators were the main source of energy on the island but were old and needed to be replaced. The average load on Geochado is 124 kW, with a peak demand of 305 kW. Recently, wind turbine generators, PVs

and ESS were installed on Donggeochado as part of another project.

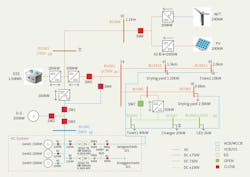

In Seogeochado, KEPCO constructed a 1500-Vdc (±750 Vdc) distribution line to replace an existing 6.6-kVac distribution line. The new dc line connects to the renewable energy sources to supply dc power to residential customers. This LV dc project included the installation of 200-kW solar power, 100-kW wind generation, a 1.5-MWh ESS, dc electric charging points for electric vehicles and a new diesel generator. The capacity of each of the distributed energy resources was calculated using the HOMER Pro microgrid software simulation, a tool based on a hybrid optimization model for multiple energy resources, by considering site conditions, stability and cost.

An EMS for the LV dc island operation was developed and established as part of this project. Residential and commercial loads were selected from loads on the existing distribution network. The new island control room was equipped with a power management system (PMS), heat management system (HMS) and automatic demand-response (ADR) facilities, all of which were integrated with the EMS for total energy management. Overall, KEPCO aimed to improve the energy efficiency of the island by 10%. The dc island demonstration project was completed in September 2018.

Gaining Experience

The objective for both LV dc demonstration projects is to verify the dc network is more efficient than the ac network. KEPCO is demonstrating this by changing a section of its existing HV network operation to LV dc operation using the same network topology.

In addition, the utility plans to continue developing components for its dc network, such as the converter, monitoring devices, variable-speed diesel generator and operation technologies. This will result in a business model for LV dc distribution networks that, globally, are still in their infancy. It also will give KEPCO the knowledge and experience to expand its application of LV dc distribution networks at home and abroad.