Pepco Manages Real-World Grid Complexity with Faster-than-Real-Time Simulation

The electric grid is rapidly becoming more complex as centralized, fossil-based generators are replaced by renewable, inverter-based resources, such as solar PV. The inherent variability of renewable generation introduces uncertainty to electrical power system operations that can challenge grid stability. New models capable of leveraging real-time data from advanced monitoring and communications infrastructure to ensure grid reliability and resilience can help with uncertainty.

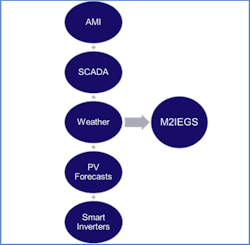

Since 2019, Pepco Holdings Inc. has served as a partner to Electrical Distribution Design (EDD) on a U.S. Department of Energy-funded project to build, test, and implement a model-based real-time analysis software architecture. The software, Model-Measurement Integrator for Ensuring Grid Security (M2IEGS), can detect abnormalities and coordinate voltage control and grid stability in real time, from transmission through secondary distribution.

I met with members of the Pepco and EDD teams to reflect on their progress as they begin the final phase of the project, field validation of lab-testing results on two of Pepco Holdings’ circuits. Nick Cincotti, senior project manager of Smart Grid Project Execution at Pepco, Luan Watson, manager of DER Interconnection at Pepco, Harold Christopher, poduct manager at EDD, and Dr. Robert Broadwater, the project’s principal investigator and senior product manager at EDD, joined me on the call.

Project Background

I began the call by asking the team to share how they became involved with the project and became a utility partner to EDD. Watson explained that EDD and Pepco Holdings had been partners prior to this project, with EDD providing planning and analytics software. Pepco Holdings hoped to foster its existing relationship to benefit the grid and its customers. They worked with EDD to draft the concept for the DOE-funded project, which proposed the development of a system to detect abnormalities and stabilize the grid in real-time. According to Watson, Pepco Holdings saw an opportunity for such a system to “mitigate some of the challenges that we potentially foresee at high penetrations of PV, serving as a utility partner to oversee the project and validate lab-testing results in the field. Cincotti noted that “as a partner on the project, Pepco Holding’s role is to more or less facilitate and implement this project on our grid testing it out for about six months to see how it works and how it compares to some of the simulations that EDD has run previously.”

M2IEGS Capabilities

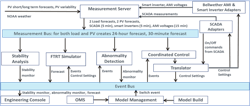

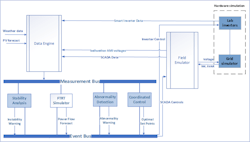

In support of the targeted project outcome, EDD developed M2IEGS as an innovative integrated model that monitors the electric system from transmission through secondary distribution using solar generation and consumption forecasts paired with real-time grid data. Pepco Holdings saw the potential value of the model’s capability to mitigate rapid system changes, such as reductions in PV generation, through coordinated control of automated line equipment.“The software is capable of performing faster than real-time,” Watson told me. “This enables the model software to “anticipate system response, and be able to mitigate those system responses based on adjusting real-time capacitor and regulator settings proactively.”

Another benefit of using the M2IEGS model is leveraging its ability to use advanced PV generation forecasting, courtesy of project partner Clean Power Research. As Mr. Watson mentioned, the PV generation forecasts allow Pepco Holdings to “better understand how solar is going to be performing and then determine the forecasted impacts that are going to be on the system and be able to get the system ready for those changes ahead of time to stabilize the grid voltage.”

Given forecasted fluctuations in PV generation, the M2IEGS software enables grid operators to schedule smart inverters to control voltage.

Field Testing

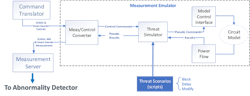

Early in the project, EDD collaborated with partners at Florida State University, the University of Delaware, and Virginia Tech to test the software and its abnormality detection capabilities in various lab environments.In the lab, the EDD team predicted that the application could save up to $180,000 in energy use per year on one of the feeders through coordinated voltage control. “We'll be using our weather-dependent load models to help us measure the energy use prior to the coordinated control and then the energy use after the coordinated control,” Broadwater told me, “And we can use those models to, I think, pretty accurately predict the difference in the energy uses.”

In other previous studies, the project team also predicted that the application could at least double the PV hosting capacity of a circuit through voltage control.

The third prediction from lab testing is the model’s ability to operate as a multi-mode control system capable of mitigating several common abnormal conditions. Test modes may include stabilizing transmission system voltage, responding to a failed voltage regulator, or detecting a cyberattack on the inverters.

Watson also mentioned that PHI is considering what capabilities it will need in its advanced distribution management systems (ADMS) and distributed energy resource management systems (DERMS) moving forward, noting that direct feedback from the field tests may inform functionalities in DERMS and ADMS development.

System Preparation and Challenges

Before the M2IEGS application can be tested on Pepco Holding’s circuits, the project team must prepare the system to communicate with and provide necessary real-time data to the application. “I typically break down the preparation for the grid into three main sections,” Cincotti offered, “our information technology leg of the project, we have our distribution automation leg, and then there's the customer pilot portion of the project, as well.”

As Cincotti told us, “Customer pilot participation is critical to utilizing smart inverters that can communicate real-time PV generation data back to our servers and feed into the M2IEGS application”.

Developing a Customer Pilot

In order to effectively test the M2IEGS application in the field, the project team identified two test circuits that met a certain condition - notably, high PV penetration and at least one large PV generator. The final test circuits include a 1.5 MW unit at Chesapeake College, which has verbally agreed to work with the project team.

After choosing the circuits, the project team needed a means to collect real-time generation data from the PV systems on those circuits. In order to collect that data to feed into the M2IEGS application, Pepco Holdings developed a customer pilot to structure data-sharing agreements with those PV system owners. They reached out to PV owners on those circuits, incentivizing them to install smart inverters and agreeing to share their PV generation data with Pepco Holdings. Mr. Watson mentioned that the project gave Pepco Holdings a valuable opportunity to examine the types of agreements, interaction models, and customer education strategies that will become necessary as the grid becomes increasingly advanced and interactive.

With agreements in place, the M2IEGS will be able to use real-time PV generation data on the circuit alongside short and long-term PV forecasts, to monitor PV generation variability. For significant variability, Pepco Holdings will be able to take voltage control action with their automatic line equipment, in tandem with inverters to stabilize voltage. In fact, the model’s use of 30-minute PV generation forecasts with one-minute step sizes enables grid operators to make control decisions and prepare for rapid fluctuations in PV generation.

Though the benefits of M2IEGS to Pepco Holdings customers likely extend beyond the installation of a smart inverter, they may be difficult to quantify at the individual customer level. As a part of its recruitment campaign for the customer pilot, the team has had to consider how to appropriately communicate the value of technology investments like M2IEGS and the smart inverters.

As Watson explained, “If you're an existing customer, you already have this interconnection agreement. Some of the benefits that [participants] are providing to the system are not necessarily specific to that customer but more so broader to the system at scale.” This customer pilot serves as an opportunity for Pepco Holdings to better understand what a larger program structure and agreements may look like, particularly on circuits where there are potential hosting capacity constraints.

What’s Next?

Though a lot of progress has been made so far on system preparation, the project team informed me that they have not yet begun implementation. Cincotti said, “We're still going through the recruiting phase for the pilot.” The Pepco Holdings’ team is in the process of onboarding a solar vendor who can help with recruiting as well as the design and construction of upgrades as the project moves forward. Aside from the ongoing recruiting and vendor onboarding, the PHI team noted that they were nearly ready to deploy the M2IEGS software from an IT and distribution automation perspective.

Cincotti mentioned that the project team was close to having everything ready to go and is preparing to begin monitoring real-time field conditions with the M2IEGS application once it has been deployed and tested. Ideally, Cincotti noted, Pepco Holdings is planning to start monitoring in Q4 this year using the M2IEGS application, with the full, coordinated control aspect, launching in Q1 of 2024.

Cincotti told us. “I think if we're able to build the case and show the benefits. I think the rest of it will fall into place.”

Managing Complexity on the Future Grid

Before we ended the call, Broadwater shared a few of his takeaways on the value of the M2IEGS application beyond this project and across the entire industry. Broadwater said, “I think this is all about managing complexity when it comes right down to it. Our system is becoming much more complex. The complexity of the electrical power system is just growing by leaps and bounds with all of the different things that we're doing to it. If we're really going to get full benefit out of all of this, we've got to manage that complexity, and the way we manage complexity is with models.”

Broadwater highlighted the ability of the M2IEGS application to solve power flow analysis from three-phase transmission all the way through the secondary distribution system, noting the importance of modeling secondary distribution, especially when interconnecting PV. Additionally, Broadwater said, “Our team’s desire is to use this project to educate the industry about the non-matrix solution that M2IEGS uses to solve the power flow analysis.”

Overall, Broadwater emphasized the value that M2IEGS can provide to utilities like Pepco Holdings irrespective of its coordinated control capabilities. The application has an unprecedented ability to consider real-time AMI, SCADA, and inverter measurements alongside solar and load forecasts to analyze a model of the entire system.

The Department of Energy-funded M2IEGS project will culminate in a field demonstration of modeling and simulation software designed to improve grid resilience using real-time and forecasted system data. Broadwater and representatives from PHI will be joining a panel discussion on Wednesday, September 13, at RE+ in Las Vegas, NV, to discuss key findings and takeaways from this DOE-funded project.

Weston Dengler is Senior Analyst, Research & Industry Strategy, Smart Electric Power Alliance (SEPA). Weston joined SEPA’s content team in December 2021 and supports the association’s microgrids for resilience and DER economic valuation work. Weston comes from a consulting background, where he supported utility DER program design and evaluation, emergency preparedness exercises, and energy resilience projects for a strategic and technical consultancy. He has also served in roles related to utility tracking and energy benchmarking, energy efficiency and renewable energy programs, sustainable product procurement, and demand-side management. Weston has a MA, Energy and Environment and a BA, Environmental Science from Boston University.