The largest vertically integrated electric utility in the state of Paraná in southern Brazil, Companhia Paranaense de Energia supplies power to some 4.5 million customers. The utility’s infrastructure mainly comprises an overhead line transmission system with a voltage range from 69 kV to 500 kV. Since the 1970s, Companhia Paranaense de Energia (Copel) has been developing compact design configurations for 69-kV and 138-kV urban transmission lines erected in densely populated cities, where there is a lack of physical space for large supporting structures.

The utility uses compact urban transmission lines as an alternative to the much more expensive underground cables. The compact lines are regarded as being aesthetic and having a more acceptable environmental impact.

First Compact Lines

In 1970, Copel’s main goal was to develop an overhead transmission line configuration that could be constructed in very populated urban areas, with the use of underground cables being too costly. For this reason, it was important the configuration have a high degree of safety and be aesthetically compatible with an urban setting.

Copel started by studying compact transmission lines based on the 1978 first edition Transmission Line Reference Book: 115-138-kV Compact Line Design, commonly known as the Blue Book, from the Electric Power Research Institute (EPRI). It was noted the research showed it was possible to construct a 138-kV transmission line with 0.9-m (3-ft) spacing between the phase

conductors.

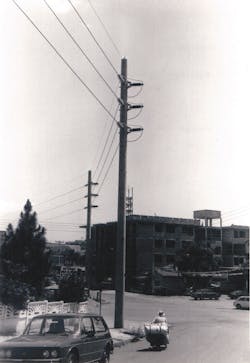

The design Copel adopted for its first compact urban transmission line—erected in 1979 in Curitiba, the capital city of Paraná, which pioneered the construction of compact urban transmission lines in Brazil—was a more conservative 1.4-m (4.6-ft) spacing between the phase conductors at 69 kV. At 3.5 km (2.17 miles) long with span lengths averaging 130 m (426 ft), this urban transmission line was constructed using circular concrete poles and porcelain line-post insulators to support the 397.5-kcmil aluminum core steel-reinforced (ACSR) phase conductors.

These studies led to the development of the next generation of urban transmission lines. The conductors were replaced with 636-kcmil ACSR conductors to reduce the surface electric field. The average span length was reduced to 80 m (262 ft), and the overhead ground conductors were changed to 4/0 ACSR cables, replacing 2/0 AWG. An auxiliary cable not previously strung also was included. The clearance between the phase conductors was reduced to 1.2 m (3.94 ft) for 69 kV.

Following the successful operation of 69-kV urban transmission lines, Copel turned its attention to the development of 138-kV urban transmission lines, which previously were designed with a phase-to-phase clearance of 1.7 m (5.6 ft). Further in-house development work enabled Copel to design double-circuit urban transmission lines for 69-kV and 138-kV operations in 2000. Then in 2003, the design for its first 230-kV urban transmission line was approved.

These urban transmission lines have been developed and erected successfully by Copel since the late 1970s. Currently, the utility has more than 500 km (311 miles) of 69-kV and 138-kV urban transmission lines installed in Paraná, with the majority erected in large cities. This represents approximately 10% of the 69-kV and 138-kV transmission lines in commission in Paraná.

Line Characteristics

Urban transmission line design studies must consider physical construction features and important environmental characteristics associated with the operation of a high-voltage transmission line in a densely populated location. This includes consideration of corona, audible noise, radio interference, short-circuit current distribution and levels, induced voltages, step and touch voltages, and 60-Hz electric and magnetic fields.

These are the main physical characteristics of the urban transmission lines designed by Copel:

• Circular concrete single poles, up to 26 m (85.3 ft) in height

• Line-post insulators for tangent structures (composite or porcelain)

• Single 636- or 795-kcmil phase conductors (69 kV and 138 kV)

• 230-kV configuration: 2 x 397.5 kcmil bundle per phase

• Overhead ground wire and auxiliary conductors strung below phase conductors

• Narrow right–of-way (ROW)

• Reduced phase-to-phase clearance, including 1.2 m (4 ft) for 69 kV, 1.7 m (5.6 ft) for 138 kV and 3 m (9.8 ft) for 230 kV

• Grounding system with three copper-weld rods, each 6 m (19.7 ft) in length, laid 6 m (19.7 ft) apart and placed in a straight line

• Very short lengths of overhead line, frequently no more than 10 km (6.2 miles)

• Average span length: 80 m (262 ft)

Circular concrete single poles were chosen for the overhead line supports, as this type of structure is common in Brazilian urban areas, erected on the 13.8-kV distribution networks and for the telecommunications grid. However, despite the high-voltage levels, the structures are not viewed as too tall by the local community, which means they have an acceptable visual impact.

The use of an auxiliary cable strung below the phase conductors is regarded as a safe configuration because the cable, which is grounded, enables the use of very fast line protection in the event of an insulator or cable failure. The auxiliary cable also provides the metallic circuit for the zero-sequence fault current and reduces the current injected into ground, reducing the step and touch voltages in fault situations. Additionally, the auxiliary cable provides a passive loop, reducing the magnetic field level at ground level.

The overhead line phase conductors installed are far larger in diameter than electrically necessary. However, the 636- and 795-kcmil ACSR conductors are installed with very low mechanical tension (about 500 kgf), which means they will not fail because of cable vibrations. Copel also uses these conductors for the corona effect and surface electric field, which is much more intense because of the reduced distance between phases. Thus, the conductors reduce the audible noise and radio interference. For similar reasons, it is used on twin-conductored 230-kV urban transmission lines.

The insulators used are the line-post type because they reduce conductor swinging, thereby enabling a reduction in the clearance between phase conductors.

Super-Compact Lines

In 2013, Copel undertook its first studies to develop a compact design for 138-kV urban transmission lines based on the design used for the 69-kV urban transmission line infrastructure. The utility planned to use the same structures, cables and grounding system as well as uprate the circuit voltage to 138 kV. This new configuration was called the super-compact 138-kV urban transmission line, designed with a phase-to-phase conductor clearance of 1.2 m (3.9 ft).

With more than 40 years of experience erecting conventional urban transmission lines, Copel’s engineering staff was apprehensive about both the possibility of reducing the distance between phases even more on 138-kV urban transmission lines and the unanticipated restrictions this level of compaction would impose on the transmission system. This led to further studies and tests to determine the impact of this compaction on the operational performance of the 138-kV lines. The testing included examining the operational performance of the following:

• Corona and audible noise

• Radio interference

• 60-Hz electric and magnetic fields

• Air gap strength for lightning impulse and switching surges

• Phase-to-phase switching surges

• Lightning surge performance

As a result of the compacted design and locations where these urban transmission line circuits would be erected, corona proved to be one of the most critical issues, because it is necessary for the urban transmission lines to exhibit a very low noise characteristic. A laboratory test was carried out whereby an equivalent voltage was applied to a single cable and the audible noise measured. The results proved to be satisfactory even when voltages higher than 138 kV were applied; the measured noise level was considerably less than the Brazilian standard of 50 dB.

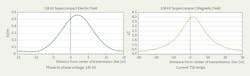

Mathematical models were used to determine the magnitude of the electric and magnetic fields. In Brazil, the current limits for electric and magnetic fields are 4.17 kV/m (1.27 kV/ft) and 200 micro Tesla (µT) measured 1.5 m (4.92 ft) above ground on the right-of way border. Even when considering very high c urrents (750 A) and a 5% overvoltage (145 kV), the results were 0.56 kV/m (0.17 kV/ft.) and 4.2 µT, well less than the Brazilian standard.

Because of the high degree of compaction and configuration of the super-compact urban transmission line, the air gap strength for both impulse lightning and switching surges under dry and wet atmospheric conditions were evaluated. The statistical basic lightning impulse insulation level (BIL) and basic switching impulse insulation level (BSL) were obtained from the critical flashover voltage (CFO). The test was performed to ascertain the CFO, which represents the probability of 50% flashover for a given impulse level (U50%). For transient stresses, the required withstand voltage should be 90% of withstand voltage of the air gap. It is determined as a function of the U50% considering a standard deviation of 1.3. The results for BIL and BSL were as follows:

• 550-kV BIL level

• 650-kV air gap basic lightning insulation level

• 598-kV air gap switching impulse strength (dry) level

• 610-kV air gap BSL (wet) level

Phase-to-phase switching surges were studied using the methodology outlined in the EPRI Blue Book. As the super-compact urban transmission line is very short—approximately 4 km (2.5 miles) in length—with about 50 poles and a failure risk of 1%, the CFO according to the Blue Book is 558 kV. This information then was used to calculate the 99% withstand-strength voltage of 460 kV.

Copel concluded the geometry of super-compact urban transmission lines was satisfactory for transmission lines as short as 4 km (2.5 miles). Further studies have been performed by Copel and the Technological University of Paraná (UTFPR) to calculate the switching surges and lightning performance using the Electromagnetic Transients Program/Alternative Transients Program (EMTP/ATP) software to develop a model for the super-compact urban transmission line surge impedance. Lightning performance studies, made with IEEE Flash software, show a satisfactory rate for Copel of 7.82 flashovers per 100 km annually (12.6 flashovers per 100 miles annually) for urban configurations.

First Super-Compact Line

The first 138-kV super-compact urban transmission line was built replacing a section of an existing conventional overhead line in a metropolitan area of Curitiba. The Fazenda-Iguaçu-Fazenda Rio Grande transmission line is 7 km (4.4 miles) in length. The conductors are supported by concrete poles with an average height of 24 m (78.7 ft) and span lengths of about 70 m (230 ft). The phase conductors are Grosbeak ACSR and 4/0 Penguin ground wire.

Based on the satisfactory results of all the studies and tests, Copel initially selected a 1-km (0.62-mile) section of the circuit to be replaced, which resulted in the reduced clearance between the phases being accommodated using additional holes in the concrete poles. The overhead line was designed using PLS-CADD software to verify the mechanical characteristics that included concuctor motion and stress. The transmission line accessories were the same for the conventional and super-compact sections of the circuit and no major modifications were needed to the design criteria Copel normally used.

Since commissioning, there have been no major outages or complaints regarding the visual impact and interferences from corona, audible noise and electric magnetic fields. The only circuit outage to date was caused by a lightning strike on a conventional compact section.

Advantages and Disadvantages

Copel has adopted as standard the compact overhead line for all its new 69-kV and 138-kV circuits as well as when changes or modifications are required to existing 69-kV and 138-kV overhead lines erected in urban area. To date, no further super-compact urban 138-kV transmission lines have been erected, but the design is available for use when there is a need to upgrade existing 69-kV lines to 138 kV. For the long-term, Copel has compact designs approved for use on 230-kV transmission lines.

Compact and super-compact urban transmission lines are costlier than conventional transmission lines erected on lattice towers because of the high safety factor required and shorter span lengths. Also, because of the reduced phase conductor clearances, it is not possible to use live-line procedures, so maintenance work on such circuits must be isolated.

Copel’s experience with compact transmission lines has improved with the development of the super-compact configuration for urban transmission lines, and even more overhead transmission line design improvements are planned.

For more information:

Copel | www.copel.com

UTFPR | http://portal.utfpr.edu.br