Due to global climate change, the frequency and intensity of wildfires is increasing. This poses severe problems for utility companies as both distribution and transmission lines are frequently routed through grasslands and forested areas to minimize aesthetic impacts to urbanized areas. Having been affected by wildfires in the past, Southern California Edison (SCE) has taken a proactive approach to fire harden the structures on its system.

SCE has adopted a fire test protocol that simulates the heat and intensity of wildfire. It has tested a variety of products to that protocol to determine the effectiveness of that product to either protects its structures from wildfires or to increase the fire resistance of its structures when exposed to wildfires.

Fire Testing Protocol

The fire testing protocol was developed by Mark Ackerman of the University of Alberta and will be used as the protocol of choice for all fire testing discussed. In the Ackerman test, a full-sized pole is embedded in the ground. A 12 ft (3.66 m) high shroud is then placed around the pole. An annular space is maintained between the shroud and the test pole so that the pole is exposed to flames from all sides.

At the start of the test, propane is injected into the shroud and ignited. The flow rate of the propane and the time duration of the test can be adjusted to create test conditions to simulate different wildfire fuel types. Measurements of conditions inside the shroud include heat flux to the shroud boundary and combustion product temperature. These measurements are used to gauge test conditions and test to test variability. For the SCE tests, test temperatures of approximately 1,800ºF (982ºC) to 2,100ºF (1,149ºC) were achieved for 3 minutes.

After a pole is exposed to the test, it is full-scale break tested. A comparison of the break test results between the fire tested pole and a control set of poles not exposed to the fire testing will determine the relative fire resistance across the materials.

Testing Poles and Their Materials

SCE has performed fire tests on a variety of different structural materials and pole types. The results varied and provided a great deal of insight on how fire impacts the material used by SCE for poles and structures. These materials included ductile iron, concrete, and tubular steel. In addition, SCE tested two fire shield technologies using fiber reinforced polymer (FRP) materials to protect FRP poles and a fire mesh to protect wood poles. Let’s look into the process in a little more detail.

The fire testing took place at the Southwest Research Institute (SWRI) facilities. SCE subjected ductile iron poles manufactured by McWane to the fire testing procedures. After the test, the two fire exposed poles and one control pole, were placed under full-scale destructive testing at the EDM International lab in Ft. Collins, Colorado, to observe possible impacts on strength and deflection from the Ackerman test. The Ackerman and EDM tests concluded that there was no negative impact on the strength or deflection capacity of the ductile iron poles due to the testing. The full-scale testing revealed that the fire tested poles on the average had a slight increase in strength and less deflection than the unburned control pole. This suggests that annealing of the fire tested poles could have occurred which increased the pole strengths.

The next fire test was performed at the SWRI facilities on spun cast concrete poles manufactured by Valmont. Subsequent to the fire tests, full scale break tests were performed to determine the relative effects which wildfires may have on spun concrete poles. The purpose of these tests was to determine the reduction in strength after each pole was exposed to a simulated wildfire. Three poles were used in this test. One pole was set aside as a control pole, one pole was subjected to a 2-minute burn and one a 3-minute burn. The control pole was not fire tested and used as the baseline for strength and deflection comparisons with the fire tested poles. The 2-minute fire test sample did not exhibit a significant decrease in reduction of strength and deflection when compared to the control pole. However, the 3-minute fire test sample did experience a reduction in strength and deflection capacity of approximately 23% and 17% respectively; nevertheless the 3-minute test values well exceeded the ANSI design load of 2,925 lbs. (13.01 kN). Considering that these tests were performed on single poles, additional testing should be performed to develop a statistical sample which would provide a better indication of the performance of these poles under wildfire conditions.

Tubular steel poles manufactured by Valmont were the next poles to be fire tested at the SWRI facilities. Subsequent to the fire tests, full scale break tests were performed to determine the relative effects which wildfires may have on tubular steel poles. The purpose of these tests was to determine the reduction in strength after each pole was exposed to fire. Similar to the tests for the spun cast concrete poles, three poles were used for this test. One being a control pole which was unburned, with one pole being subjected to a 2-minute test and one pole being subjected to a 3-minute burn. Again the control pole would be the pole to which the strength and deflection results of the 2-minute and 3-minute burn tests would be compared. Subsequent to the fire tests and the full-scale break tests, it was found that for both the 2-minute and 3-minute fire tests, the tubular steel poles performed very well as there were no strength reductions and the deflections were statistically similar.

Add-On Fire Protection

The FRP fire sleeve developed by Creative Pultrusions (CP) has proven to be a valuable addition for pole fire protection. This FRP fire sleeve is installed over their pultruded FRP pole. The pultruded fire sleeve adds a significant level of fire protection to the pole as the sleeve is slid over the pultruded pole during production and acts as a barrier to protect the pole from wildfires.

CP has tested their fire sleeve to the fire test at the SWRI. In this test a 45’, class 1, fire sleeve protected pole was exposed to a temperature of 2,050°F(1,121°C) for two minutes. During the test the surface temperature of the pole under the fire sleeve was monitored with a thermocouple. At the conclusion of the test, it was noted that the surface temperature of the pole stayed below the temperature where FRP material degradation would occur. After the fire testing, the pole was load tested to failure. The pole failed at a load that was 63% higher than the rated class load of the pole of 4,500 lbs. (20.02 kN). Based on these results, it appears that the CP fire sleeve is an effective barrier in protecting the CP pole from wildfires as the surface temperature of the pole stayed below the material degradation temperature.

RS Technologies has developed a FRP fire shield that goes with its manufactured modular composite pole system. In this system, RS manufactures nine basic modules, from these nine modules various pole sizes and classes can be assembled by combining the various modules. The RS fire shield is an FRP shell that is installed over the RS FRP pole. The shield is intended to serve as a protective barrier between the wildfire and the pole. In its design, when exposed to a wildfire, the shield would absorb the heat energy of the fire while protecting the pole from the fire and strength loss. For SCE, the shield is approximately 3/16 in (4.76 mm) thick and is installed from ground line to a height of 20 ft (6.1 m) above ground.

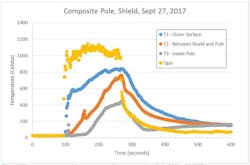

In a test of the RS fire shield performed using the testing protocol in Tilbury, Ontario Canada, RS installed thermocouples at four locations to obtain temperature data on the 45’, class 1 pole. The locations of the thermocouples were on the inside of the shroud (to obtain the temperature of the gas within the shroud), on the outer surface of the fire shield, between the fire shield and the surface of the pole and on the inside of the pole. A 3-minute test was performed and a time versus temperature plot was created for all four thermocouples.

In reviewing the data and the time versus temperature plot, while the maximum gas temperature ranged between 1,832°F (1,000°C) to 2,102°F (1,150°C), the temperature between the fire shield and the surface of the pole rose slowly but stayed well below the maximum gas temperatures at the end of the 3-minute test. The results of the test show that the fire shield is effective in protecting the surface of the pole from the severe heat of a wildfire.

After the completion of the fire testing, the fire shield was removed to visually examine the condition of the surface of the pole. While the shield was extensively damaged, the pole behind the shield was discolored, however, it was undamaged. Subsequent to the fire test, RS performed a full-scale break test on the pole. The pole failed at a load that was 106% higher than the rated class load of the pole of 4,500 lbs. (20.02 kN). Thus, the fire shield protected the pole such that the pole continued to retain its full strength after the simulated fire test.

While SCE looked at materials for new poles, it also examined a multitude of systems to protect its existing wood poles in high fire prone areas. After a lengthy testing and evaluation program, a fire mesh manufactured by Genics was selected for further testing to see how it would perform under wildfire conditions.

The fire mesh is proprietary metal screen material which is coated with an intumescent material. The fire mesh is installed by wrapping the mesh around the wood pole to be protected and stapling the mesh in place. The mesh allows the wood pole to acclimate to the environment around while protecting the pole from wildfires. When the mesh is exposed to the high heat of a wildfire the intumescent material expands and forms an insulating barrier around the pole to protect it from the heat and flames.

Initial testing was performed at the Western Fire Center in accordance with the ASTM draft wood pole fire test standard on several wood pole samples. After the test, a qualitative analysis was performed to determine the effectiveness of the fire mesh in protecting the wood pole samples. The analysis showed that the fire mesh provided excellent protection of the wood pole samples as the average calculated loss of strength was 1.46%.

The fire mesh was subsequently tested at the SWRI to the test product on full length wood poles. A three-pole test program was used where one pole would be unburned and used as a control, one pole would be subjected to a 2-minute burn with one pole being subjected to a 3-minute burn. Subsequent to the fire testing, the poles were full-scale break tested. When comparing the break test results of the poles subjected to the 2-minute and 3-minute burns with the control pole, it was found that no strength degradation was seen in the poles subjected to the fire tests. Thus, the fire mesh was determined to be an effective product in protecting wood poles in wildfires.

Based on the research and testing that was performed, SCE decided to initially implement two products into its system. These were the RS fire shield composite poles and the fire mesh manufactured by Genics. While the performance of these products was only evaluated by simulated fire testing, the Lake Fire in 2020 provided SCE with an opportunity to see how these products performed in an actual wildfire.

Real World Experience

On Aug.12, 2020, the Lake Fire started in a remote area north of Castaic Lake in Los Angeles county. It quickly spread from a few hundred acres to several thousand acres as it pushed north. As the fire grew it created very dangerous conditions due to steep topography filled with thick vegetation exacerbated by high ambient temperatures and low relative humidity. The fire consumed over 31,000 acres (12,545 hectare). Thirteen RS composite poles with the RS fire shields and three wood poles with the fire mesh were affected by the fire.

All 13 RS fire shield composite poles were standing after the fire. SCE retired six of the poles for detailed post fire evaluations. The evaluations consisted of two parts – a visual inspection and structural evaluation.

Visually, the extent and types of damage witnessed on the fire shield of the poles after the Lake Fire were comparable to the damages seen in the simulated fire testing in the Ackerman test. This gave SCE a high confidence level that the testing protocol accurately simulated real-world wildfire conditions.

The visual damages found on the fire shield included:

- Discoloration within the shielded area

- Loose glass fibers in shield

- Textured glass fibers

- Ash colors embedded into the pole

- Charred shield

- Discoloration above the shielded area

- Broken glass fibers

- Hanging glass fibers

The damage observed on the fire shield from RS did not penetrate through the thickness of the shield, so it was evident that the shield protected the pole from the flames.

Subsequent to the visual evaluation a structural evaluation was performed to see if the poles experienced any strength degradation due to the wildfire. For the structural evaluation, four of the six retired poles were full scale tested to failure to determine the effects which exposure to wildfire would have on the strength and stiffness of the poles. All the poles failed at or above the RS design fiber stress values (FSV). The testing shows that the fire shield fully protected the poles during the wildfire. It also revealed that while the shield was extensively damaged, no strength degradation occurred on the poles.

Three wood poles which were wrapped with the fire mesh by Genics were affected by the Lake Fire. All three poles were standing after the fire. One of the three poles was retired due to excessive charring above the wrapped section on the pole. The extent and types of damage witnessed after the Lake Fire were comparable with the damages seen in the simulated fire tests conducted on similarly configured wood poles.

Upon close inspection of the retired pole, it was noted that the fire mesh had activated and that an intumescent barrier of approximately 0.5 in (1.27 cm) had formed. Upon removal of the fire mesh, it was found that the pole under the mesh was undamaged and continued to retain the color and look of a pole which had not gone through a wildfire. Based on our observations, it could be concluded that the pole would continue to retain its full strength even after the wildfire. This shows that the fire mesh can effectively protect a pole in a wildfire.

Lattice Steel Under Wildfire Conditions

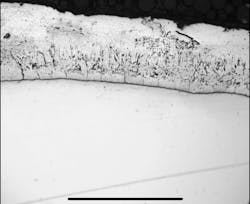

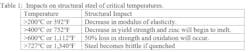

In 2020 the Bobcat fire impacted several of SCE’s 500kV lattice towers. While steel does not burn, exposure to high heat could change the material properties of the steel possibly reducing the steel strength or making the steel brittle.

SCE has worked with Matergenics to investigate this phenomenon. When fire damaged members of the lattice towers were replaced, samples of steel members exposed to the wildfire were sent to Matergenics for lab analyses.

The analysis found that with increasing temperatures of a wildfire, the physical and mechanical properties of lattice steel could change. A summary of these changes is provided on the left.

Thus, while a structure may appear to have survived a wildfire unscathed, the testing revealed the potential loss of mechanical strength and ductility could reduce the strength of the structure to levels below its required factor of safety. This could lead to catastrophic failure in the future. To mitigate this possibility, a detailed investigation on the structural steel should be performed to determine if the steel has been negatively affected by exposure to a wildfire.

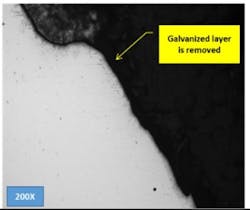

Lattice steel members are typically protected by galvanizing. When exposed to high heat, the galvanizing layer could be melted and destroyed. This could lead to long term corrosion issues. Thus, after a fire, galvanized structures should be inspected and tested for remaining galvanized layer thickness. A close-up visual examination, preferably under moderate magnification, and coating thickness measurements should be made after fire exposure.

Clinton Y. Char ([email protected]) is the manager of the Transmission Engineering, Poles Engineering group at the Southern California Edison, Co.

He has B.S. and M.S. degrees in civil engineering and is a registered professional engineer with more than 30 years of transmission and distribution experience.

He is a member of ASCE and is currently involved with two ASCE standards committees. He has made numerous conference presentations and has published 20 technical papers.

Brian Flynn ([email protected]) has worked as a technical specialist/scientist of wood products for Southern California Edison since 2008 and expanded from wood products to pole specialist in 2019 when he took over as composite pole expert. He currently represents Edison on two national standard committees (AWPA and ANSI) which set standards for the utility wood industry. Flynn has a bachelor of sciences degree in forestry and natural resources from California Polytechnic State University, San Luis Obispo. He also has a master’s degree in business administration and is Lean Six Sigma trained.

Sergio Arambula ([email protected]) is currently a transmission engineer under the Transmission and Distribution Engineering Organization at Southern California Edison. He has a B.S. in civil engineering from Washington State University and an M.S. in civil engineering from Purdue University. He has published and presented at numerous conferences such as TSDOS, EDM International, and EPRI IUWG.