Understanding Wind Load Design for Power Lines

Typically when extreme wind events occur, the maximum gust wind speed is reported. This single number is often readily compared to wind design criteria in building codes, especially if engineered structures are damaged. Conclusions are drawn. Is the comparison this straightforward? This isn’t the case for power lines.

A new ASCE Loading Standard is currently under development entitled “Minimum Loads for Structures Supporting Overhead Power Lines”. It is expected that, upon committee consensus and public comment, that this standard will become accepted practice on the overhead power line (OPL) industry.

As is typical of any design standard, the nominal requirements for structure capacity will be related to a threshold of risk. That is, how likely is it that the design load will be exceeded? For environmental loads such as wind, this is often expressed in terms of Return Period or Mean Recurrence Interval (MRI). Each of these probabilities are often expressed in terms of years. The MRI of the design wind speed is often used to assess, or sometimes compare, the robustness of a structure.

In recognition of the ever-increasing important role that electricity has in modern society, the design wind speed MRI used for OPL structures has been compared to other design codes used in the United States. This article addresses some key differences that may not be considered based on comparison of the design wind speed MRI alone.

At First Glance

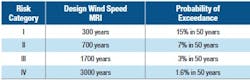

The provisions of ASCE/SEI 7: Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE 7) are used for structural design throughout the United States. ASCE 7 classifies a structure based on the intended use or occupancy by Risk Category, as summarized below:

OPL structures are exempt from ASCE 7 provisions, rather ASCE Manual of Practice No. 74: Guidelines for Electrical Transmission Line Structural Loading, 4th Edition (ASCE MoP 74) is referenced. In contrast, the nominal design wind speed MRI in ASCE MoP 74 and 2023 NESC Rule 250C is 100 years, with a corresponding probability of exceedance of 39% in 50 years. The probabilities of exceedance given would be interpreted as relevant to any given structure in a line (i.e., structural reliability), not all structures comprising a line (i.e., line reliability).

Previous versions of ASCE MoP 74 and NESC were based on a nominal design wind speed MRI of 50 years, which corresponds to a probability of exceedance of 64% in 50 years. This would seem to imply that for any given OPL structure, the design wind speed is more likely to be exceeded than not over a 50-year nominal structural lifespan.

On the surface, it would therefore perhaps not be an unreasonable view that an individual OPL structure may be under-designed compared to the desired and intended service. However, while outages and failures may be observed during some high wind events, the majority of OPL structures designed to these levels do not experience failure over their lifespan. This suggests that although the design wind speed may be exceeded, the structure does not fail due to additional capacity gained from other considerations in the design.

Power Lines Are Unique Systems

Power lines are unique systems characterized by different design constraints and challenges compared to building structures. An example is that tolerance of failure is acceptable at a lower level than occupied building structures for reasonable reasons. A typically low direct consequence of failure to life safety, potential re-routing affording redundancy, and preparedness for restoration are among these reasons.

Failure containment is also a strategy that can be applied to limit the extent of damage in the case of an extreme event. Additionally, many transmission structures are tested to failure at full-scale, leading to an improved understanding of capacity compared to most structures. Both failure containment and restoration planning will be addressed in the new ASCE Loading Standard.

It is then evident that significant differences in the consequence of failure exist between OPL structures and building structures in terms of life safety and societal impact. This is not to say that maintenance of electrical service is not extremely important in today’s society. Rather, it is a reasonable application of engineering to balance these unique characteristics with the objective of providing efficient and affordable power. To consider this balance, it becomes necessary to look beyond the design wind speed MRI alone.

Power Lines and ASCE 7

The current extreme wind load provisions in ASCE 7 are based on ultimate strength design. The use of any design wind speed MRI in the current provisions of ASCE 7 inherently assumes a load factor of 1.6 for extreme wind. These design wind speed MRI were developed to be consistent with the accompanying wind loading procedures in the standard.

Consistency is important. Notably, the wind loading procedures used in current OPL guidelines and recommendations differ from those forming the basis of ASCE 7. One example of this is that the wind loading procedures in ASCE 7 allow for a reduction in the applied wind pressure though the use of a Wind Directionality Factor (Kd). This parameter is assigned a nominal value of 0.85, and results in a 15% reduction in the design wind pressure applied for wind loads on most building structures. ASCE MoP 74 and other OPL design procedures do not consider a corresponding reduction and apply a fixed value of 1.0 to the Kd parameter.

In other words, the full Basic Wind Speed and resulting design pressure is applied at any and all directions to calculated design wind loads for OPL structures. Using this approach, the transverse loading direction often results in the highest load due to the contributions of the OPL wires. The implication of this is that direct application of the design wind speed MRI in ASCE 7, along with typical OPL wind loading procedures, would substantially exceed the design intent of ASCE 7. The mathematical rationale is beyond the scope of this article but will be documented in the new ASCE Loading Standard.

In summary, the following comparative statements can be made between ASCE MoP 74 and ASCE 7:

- Using a 50-year MRI wind speed with the wind load procedures in ASCE MoP 74 satisfies the intent of using a 120-year MRI wind speed with ASCE 7 wind load procedures.

- Using a 100-year MRI wind speed with the wind load procedures in ASCE MoP 74 satisfies the intent of using a 250-year MRI wind speed with ASCE 7 wind load procedures.

- Using a 300-year MRI wind speed with the wind load procedures in ASCE MoP 74 satisfies the intent of using an 800-year MRI wind speed with ASCE 7 wind load procedures.

In other words, the application of a particular MRI wind speed with ASCE MoP 74 (and similar) procedures is not equivalent to the use of the same MRI wind speed with ASCE 7 procedures. While the above difference is significant in and of itself, other attributes of power line structure design are also worthy

of discussion and are examined in the following sections.

Synergistic Designs

The capacity of OPL structures is often the product of application of a multitude of load cases – a synergistic design capable of resisting the applied loads. Among these are guidelines and recommendations, legislated loads, historical load cases, and project- or owner-specified load cases. Other examples likely exist as well.

A notable aspect of this design approach is that there will often not be a purely dominant load case controlling every component of every structure in a line. Rather, a OPL structure will be a product of consideration of this wide range of load cases and resulting demands. Among the variables in play are structure type, topography, line angle, OPL wire span, location, and project-specific criteria.

Examples have been shown for some basic designs which could resist very high MRI wind speeds due to the capacity provided by other load cases considered in the design. In other words, increasing the design wind speed MRI for these structures would have no significant impact of the final design. However, this outcome is not consistent for every structure in all locations.

These aspects further illustrate structural capacity which could be overlooked when only comparing the design wind speed MRI. For practical reasons, these types of comparisons are not commonly made on projects. If it were, it would likely be a difficult exercise. It is, however, likely a significant contributor to the robustness obtained in current OPL design practice. Unfortunately, these contributions to the design are not publicly known even though they may provide a more reliable design. Implementation of the new ASCE Loading Standard will provide more uniformity in these design considerations across the industry.

Considerations Beyond Calculated Risk

Beyond the calculated risk of environmental loads associated with MRI, power line reliability is impacted by several other hazards and considerations. The scope is somewhat reduced by grouping these as environmental hazards (e.g., wind, ice, seismic) and operational hazards (e.g., importance, maintenance, redundancy, and cascade failure prevention unbalanced wire loads). Any targeted risk level will never be exact as uncertainty exists everywhere.

One example of this is the choice of exposure category for wind and whether this assumption persists over the lifespan of the line. This is often addressed by assuming an open terrain exposure, even in cases where the surroundings may be more built-up or heavily forested. While the former is a prudent approach due to the uncertainty involved, it introduces conservatism in the design. This is often forgotten if the resulting wind loads are scrutinized later in the project or when the design wind speed MRI is compared with other criteria.

An additional consideration that must be addressed is failure due to vegetation encroachment or wind-borne debris. These aspects are often more critical for distribution lines as opposed to transmission, but the reasoning is similar. For transmission, the hazard due to vegetation encroachment can be managed to a reasonable level as an effort to mitigate risk of occurrence. Further discussion of vegetation hazards is not provided here but is assumed to be reasonably managed for transmission lines. This is a more

challenging task for distribution lines.

In Closing

Wind loading procedures and criteria used in the US OPL industry have evolved alongside those for other structures and notable differences do exist. As discussed earlier, there are several reasons for these differences. However, comparisons between the wind speed MRI used in ASCE 7 and those commonly used in the power industry are often made in the context of design wind speed MRI alone. This does not recognize the differences in the wind loading procedures, and more broadly the expected performance, used in the respective design approaches.

As work continues on the new ASCE Loading Standard the design criteria in ASCE 7 should be considered, but not necessarily define the eventual intent, specifications, or criteria. As clearly stated in the Scope of ASCE 7, the wind loading provisions have been calibrated to produce an “intended performance level”. When compiling the wind load criteria for the new ASCE Loading Standard, the “intended performance level” of the document is being discussed and established with the acknowledgement that it may differ from that of ASCE 7.

Looking to the future, ongoing discussion on reliability and resiliency at the structural, line, and grid levels will continue to push the “intended performance level” forward into later editions of the new ASCE Loading Standard.

About the Author

Thomas G. Mara

Tom Mara is a wind engineer and Associate Principal with CPP Wind Engineering, Inc. He is a registered Professional Engineer in Ontario, Canada and several US states. He obtained his PhD in Civil Engineering at the University of Western Ontario. Tom has been involved in the field of wind engineering since 2005 and has been involved in several ASCE committees, currently including the new ASCE Loading Standard committee and the ASCE Standard 48 committee.

Leon Kempner Jr.

Leon Kempner Jr is the principle Civil (Structural) engineer for the Bonneville Power Administration (BPA). He is a registered Civil Engineer in Oregon and Washington States, USA. He obtained his PhD in System Science - Civil Engineering at Portland State University. Leon has been involved in the analysis, design, and research for transmission line facilities at BPA for over 50 years. He participates in several ASCE, IEEE, and CIGRE technical committees and standards, including the new ASCE Loading Standard committee.