Peju, the largest island in South Korea, is famous for its exotic nature and mild weather. Located southwest of the mainland, the island was designated by the United Nations Educational, Scientific and Cultural Organization (UNESCO) in 2007 as a World Heritage site, which means it is recognized as being of outstanding international importance and deserving of special protection. When construction of a smart grid test bed began in one of its towns, Jeju’s importance grew for being a technological hub.

The Jeju test bed was constructed to verify existing IT technologies on a real distribution network that would help to reduce CO2 emissions and create a long-term domestic and overseas smart grid market. The test bed is located in a small town called Gujwa, which has a considerable source of wind and solar energy available for power generation. The existing stable distribution network comprised two high-voltage/low-voltage substations and four distribution feeders that could support five ongoing smart grid projects without creating any critical problems.

Involved with the Jeju test bed are 168 companies in 12 consortia, all developing technologies for the smart grid and verifying the results. Collectively, they have invested US$171 million, $68.5 million of which came from the Korean government. Many of the major domestic utilities, such as Korea Electric Power Corp. (KEPCO), Korea Telecom and SK Telecom, along with approximately 3,000 customers, are involved in these projects. Construction of the basic infrastructure and interconnection of related systems was completed in May 2011, and the entire test bed is focused on developing application programs, creating new business models and initiating global standardization of smart grid technologies. The consortium leader, KEPCO, is the only utility involved in all five of the smart grid projects.

Smart Power Grid

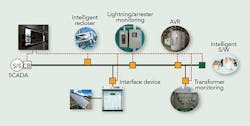

The goal of the Smart Power Grid project is to make the transmission system and distribution network sufficiently intelligent to maximize the utilization rate of existing facilities, in addition to improving energy efficiency and upgrading power quality. In the Smart Power Grid project, KEPCO is the only active player in the consortium that has 16 members. Following completion of construction, the infrastructure and the operating system, the project entered into a second phase, which consists of reviewing the results of the system operation and verifying the power quality.

Among the systems being verified is the real-time monitoring system for transmission lines using sensors on overhead lines and supporting towers. Sensors are monitoring the conductor and ambient temperatures, wind speed and direction, solar radiation and other parameters. The transmission line capacity can then be adjusted according to these measurements. The remaining primary items include a wide area monitoring system with phasor measurement unit techniques for flexible ac transmission system operation on 154-kV and 345-kV lines. In digital substations, intelligent electronic devices, which integrate the relays and control cable for switchgear in accordance with the IEC 61850 standard, have been installed to control and operate the continually expanding network intelligently.

The transformers and circuit breakers are being monitored by diagnostic sensors to capture signs of equipment aging. For the distribution network, intelligent equipment like automatic switchgear and monitoring systems for transformers and lightning arresters have been installed to secure the power quality and predict faults on overhead lines and equipment. Also, knowledge on how to operate and maintain the network in a stable condition when connected to renewable sources is an additional major project objective.

On completion of the project technologies, the test bed will be adopted into the construction standards to create a nationwide smart grid through economic analysis and standardization processes. In addition, to prepare for the future smart grid environment, the long-term plan also includes construction of the next-generation communications network, development of intelligent network technologies that are indispensable when connecting offshore wind power, development of dc transmission and operation of energy storage systems.

Smart Place

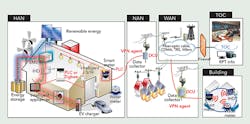

Smart Place is a project to establish the infrastructure to control energy consumption through demand response (DR) by means of a two-way communications system between the utility and its customers. KEPCO and three other consortia have established 3,000 smart places comprising residential customers, large buildings and factories in Jeju. Four system models are included in KEPCO’s Smart Place project:

• In the basic DR model, a set comprising a smart meter and an in-home display sends the pricing signal to the customer, who is then able to respond accordingly.

• Advanced DR is an extended version of basic DR but with an additional home energy management system (H-EMS) and other smart devices, such as load controllers and smart appliances. In this model, H-EMS controls the energy consumption in the customer’s home according to the real-time pricing signal and preconditions input by the customer.

• The renewable model covers the generation system using renewable sources like wind and solar energy. The generation system, which includes energy storage systems and chargers for electric vehicles (EVs), also is included in this model.

• The building/factory model is for large commercial and industrial customers. This model combines an energy management system (EMS) for buildings with an existing building automation system. This can result in a significant improvement in the efficiency of energy consumption in buildings and factories.

KEPCO has completed installation of smart appliances, such as air conditioning and refrigerators, in residential homes. By analyzing the results, KEPCO expects to be able to see how customers react to changes in the pricing signal and how those reactions eventually contribute to reducing the network peak load.

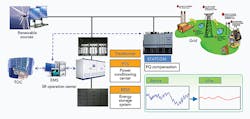

Smart Renewable

The Smart Renewable project has been promoted to improve the unstable output of renewable energy sources when connected to the existing network. As a utility, KEPCO’s main concerns are achieving a stable output from the renewable sources using a battery energy storage system and compensation of the irregular power quality with a static synchronous compensator.

For the project, KEPCO has constructed the basic infrastructure consisting of five renewable generators and installed accompanying systems, such as an EMS, a power conditioning system (PCS), a battery management system and batteries. Renewable resources have been categorized according to their generating capacity and are subject to individual testing.

For the largest capacity resources, the EMS has up to 20,000 monitoring points while smaller renewable resources — for example, a 100-kW wind and photovoltaic installation or a 30-kW micro hydro plant — have a maximum of 5,000 monitoring points. IEC 61970 has been adopted for the communications link between the operation center and the EMS. IEC 61850 is the standard used to specify the communications link between EMS and PCS.

KEPCO is preparing for power trading in the market by participating in the virtual power market with renewable energy. A new system is now used for the probabilistic forecasting of wind power. To create more profit in the liberalized market, meteorological variables are used to devise the power curve for wind and solar resources with high accuracy. By the end of this project, the economic aspects of renewable sources in a real-time pricing (RTP) environment will be evaluated and standards on power quality will be established.

Smart Transportation

It seems highly probable the development of EVs will be the way ahead for the automobile industry. According to Korea’s national Green Car Roadmap, more than 1 million EVs will be in use by 2020. KEPCO has developed and is testing various types of EV chargers in the test bed to ensure the entire distribution network is well prepared for the future widespread use of EVs. To date, a total of 40 EV chargers — most of which are ac chargers with a 7.7-kW capacity typically for public places and dc chargers with a 50-kW capacity for commercial use — have been installed in 12 charging stations in Jeju. The dc chargers take about 25 minutes to recharge a 16-kWh battery pack while ac chargers take between 5 hours and 6 hours.

In addition to EV chargers, the operation system for chargers and the customer information management (CIM) system have been established. The operation system monitors and controls the chargers, and the CIM system handles the customer information and billing process.

For the anticipated increase in the network peak load created by EVs, KEPCO is simulating various scenarios to estimate this increase in peak demand. KEPCO is also giving consideration to establishing a smart grid operation system that would monitor the entire network condition and control EV loads to limit the peak in emergencies. Technologies for battery-to-grid and vehicle-to-grid are under verification in the test bed.

Smart Electric Service

The goal of the Smart Electric Service project is to develop new services that will complement the future smart grid environment. KEPCO has implemented a pilot project for RTP with 153 residential customers in Jeju along with a web portal service named i-smart, which communicates with 170,000 high-voltage and 550,000 low-voltage customers all over the country. Based on AMR technologies, these services provide information such as the real-time power consumption and expected electricity bill to encourage customers to participate in the supplier’s DR policy and save energy.

Another important achievement is the construction of a total operation center (TOC). Built in the smart grid information center, TOC has gathered all the real-time data from the other four projects and started to provide related information to participating customers and suppliers. To meet security requirements, the cyber security center handles all possible IT problems. The integrated smart grid platform uses a common information model to smoothly interconnect all the project-related systems in accordance with IEC 61970 and 61968.

On a RTP basis, KEPCO has developed power trading services for the consortia considering two types of possible market structure. In the domestic power market, which is a cost-based pool, TOC will decide the unified power price for all consortia, which will have the network usage fee for power transmission included.

The rest of the project term will be devoted to improving the systems in the field and upgrading their performances, so as to create tariff policies that attract customers to participate voluntarily in the various services that efficiently interconnect both the demand and supply sides.

Smart Future

To bring the smart grid closer to the public, KEPCO constructed a smart grid information center in Jeju, which has hosted more than 249,000 visitors. The center allows visitors to experience future changes the smart grid will bring. According to KEPCO’s smart grid master plan, those technologies verified in the test bed will be adopted in metropolitan cities in a step-by-step program and be nationwide by 2030. Once fully implemented, it is estimated the smart grid in Korea will reduce greenhouse gas emissions (CO2) by 230 million tons, resulting in savings estimated to be some $47 billion.

In Jeju Island, Smart Korea is already on its way.

Sung Hwan Bae ([email protected]) joined KEPCO in 1979 and is currently vice president, head of the quality management department. He served as head of the smart grid office from 2009 to 2012. He holds a BSEE degree from Konkuk University, a master’s degree in electrical and computer engineering from Union Graduate College and a Ph.D. in public policy and IT from Seoul National University of Technology. He is a senior member of the Korea Institute of Electrical Engineers.