Xcel Energy Strengthens the Grid with Advanced SVCs

In 2010, Xcel Energy Inc. was tasked by Southwest Power Pool Inc. (SPP) to build out the transmission system in southeast New Mexico, U.S., because the oil and gas industry in the area had a growing need for electricity. Oil producers were asking to convert from expensive diesel to more affordable electricity for their pumps. The request from SPP consisted of a transmission system expansion of new 115-kV and 345-kV projects in the region. Spending had to be prioritized between 2010 and 2021 because of the sheer scale of the plan needed to successfully implement the request.

Xcel Energy addressed the plan by implementing projects classified as high priority. This plan resulted in initiating 44 new transmission projects, an investment of US$557 million. In 2016, two static VAR compensators (SVCs) — the China Draw and Roadrunner — were built in southeast New Mexico to support SPP’s request.

Because the northwest corner of the Permian Basin is at the edge of Xcel Energy’s service territory, the utility was challenged to provide affordable and reliable service, as it first had to overcome several concerns. The primary concerns were related to dispersed locations and very low system strength at the time of energization. A secondary concern was the extent of changes needed to strengthen the grid. Xcel Energy had to consider these concerns carefully when choosing a solution, including the configuration and the implementation of control limitations and strategies.

Location, Location, Location

Since 2011, as part of its Power for the Plains transmission expansion plan, Xcel Energy has invested in more than 1300 miles (2092 km) of new transmission lines and the upgrade or addition of over 75 substations in New Mexico, Texas and Oklahoma, with even more planned through 2021. This transmission investment represented a $3 billion dollar expenditure that was successfully implemented in the region, according to the Power for the Plains (www.powertheplains.com) website. This prompted the utility to consider two static VAR compensators, one at the Roadrunner substation to meet some specific customer requests and another at the China Draw substation to meet the forecasted load growth.

A Weak and Changing Grid

Because the new build-out was located at the edge of the Xcel Energy service territory, the transmission system was inherently weak, overcompensated and heavily loaded in relation to the prevalent fault level. To maintain stability in the area, the utility moved forward with installing the Roadrunner and China Draw SVCs. When combined with a high penetration of induction motor load, fault-induced delayed voltage recovery (FIDVR) is a valid concern, making the system prone to collapse following a disturbance. Fault-induced delayed voltage recovery is a condition when the system with a high penetration of motor load (that is, pumps, HVAC, etc.) experiences a fault that causes the motors to begin stalling. Once the system reenergizes, the motors try to speed back up, but the amount of reactive power required from the remote generators causes a voltage depression in the area that delays voltage recovery.

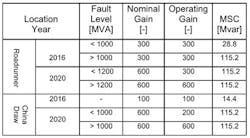

The SVCs were designed to operate in two significantly different system scenarios: an extremely weak system in 2016 and a built-out system in 2020. When the SVCs were energized in early 2016, many of the planned upgrades were not yet in service and network conditions were extremely weak. In valid N-1-1 conditions — if two consecutive outages were to occur — at Roadrunner, the fault level would be as low as 353 MVA. At China Draw, the system would be even weaker with a fault level of 272 MVA in N-0 network conditions, or normal operation. This puts the total SVC rating at both sites on par with the system fault level. That is, the short-circuit ratio (SCR) between the system and SVC is approaching unity. As a rule of thumb, an SCR with a system short-circuit strength more than three times the SVC size is recommended to ensure stability.

Stability issues primarily related to power frequency parallel resonance were exacerbated by the deployment of additional 115-kV shunt capacitors. However, many examples of SVCs throughout the world are operating in similar conditions, and this issue typically is addressed by a combining SVC topology selection and advanced control measures.

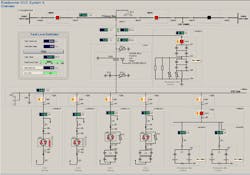

When initial studies were performed, the grid was expected to be built out and become stronger over time, from 2016 to 2020. Therefore, the two different system scenarios were used to determine the gain values for each SVC. Each SVC also controlled five local 115-kV mechanically switched capacitors (MSCs), two 14.4-MVAR MSCs and three 28.8-MVAR MSCs, at each location. In the initial system conditions, in 2016, the amount of MVAR was limited. By 2020, the build out enabled the usage of all MSCs. Xcel Energy’s system was fairly stable during the build out. The advanced control functionality provided more stability by decreasing the interactions between the electrically coupled SVCs.

Configuration and Harmonics

The transformer design is identical with a continuous rating of 110 MVA and 10-minute capacitive overload capability. Thyristor controlled reactors (TCRs) of 65 MVAR, thyristor switched capacitors (TSCs) of 70 MVAR and filter branches totaling 60 MVAR are common ratings for both SVCs. A single TCR can switch a TSC and maintain continuous operation, providing redundancy should one TCR be out of service. The two SVCs differ in the number of TSC branches. Provisions were made at China Draw to be expandable in the future with another 70-MVAR TSC.

Harmonic performance is a primary driver for TCR and filter topology selection to limit harmonic distortion on the system. One of the SVC technical requirements was to meet the IEEE 519 recommended levels on the transmission side, including the distortion harmonic levels from the network. In general, this is not feasible for an SVC with filters only on the medium-voltage bus, especially with an existing fifth harmonic voltage exceeding 5%, well above the recommended level. To mitigate amplification of the existing 115-kV system harmonic distortion, a third order heavily damped C-type filter was installed on the high-voltage bus.

Control Strategies

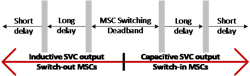

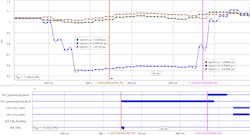

China Draw and Roadrunner each have five MSC banks assigned at the local 115-kV bus, where two are rated 14.4-MVAR and three are 28.8-MVAR. The purpose of the SVC-based local 115-kV shunt bank control is to preserve the SVC dynamic range by using high-voltage shunt banks to absorb daily voltage changes related to normal steady-state load variation. MSC switching is based on time-delayed SVC susceptance threshold levels. Two threshold levels exist for switch-in and switch-out orders, where the lower levels have a longer delay. All thresholds and delays are settable through the human-machine interface.

The banks are switched according to first-in, first-out logic. The number of breaker operations is monitored and kept equal between banks of equal rating, while hunting is limited by blocking switching after a settable number of operations in a 24-hour period. Discharge time is monitored, with the minimum time for subsequent insertion being adjustable. The banks can be selected for remote operation independent of the static VAR system (SVS) control system. If the SVS is taken out of service for any reason, the bank status is maintained and control is seamlessly transferred to the dispatch center by the supervisory control and data acquisition system.

Parallel Mode

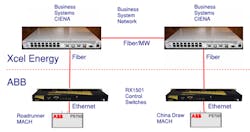

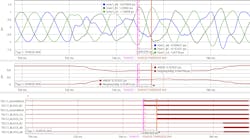

In April 2019, the dedicated fiber link was made available between the Roadrunner and China Draw substations. The parallel operation functionality was commissioned successfully and tested using the fault level estimator (FLE) with parallel mode both enabled and disabled.

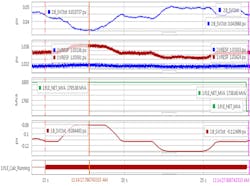

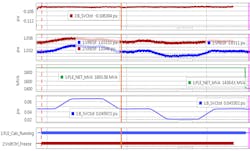

Records were taken from the digital fault recorders (DFRs) at the time of testing. Personnel were on-site at both locations to trigger the DFRs simultaneously. This was especially warranted when parallel mode was disabled, because a trigger signal does not get transmitted between the substations. During testing, when both SVCs had parallel mode disabled, the DFR was triggered automatically by the FLE action and manually at the remote end. As a result of the SVCs being electrically coupled through the 115-kV system, the 115-kV voltage at the remote SVC was held constant by compensating with a change in susceptance. The resulting estimated system strengths were 1897 MVA at China Draw and 1738 MVA at Roadrunner.

Testing also showed how parallel mode operation impacts the calculated system strength. In this case, the DFR is triggered at both SVCs by the FLE through the parallel communication. The only added signal showed the remote station recognizes the FLE is active elsewhere and freezes the voltage control of the remote station. The resulting estimated system strengths were 1439 MVA at China Draw and 1742 MVA at Roadrunner.

The results at China Draw during testing demonstrated the impact of the Roadrunner SVC when measuring the fault level with and without parallel mode. The system around Roadrunner was strong enough to not be affected by China Draw, though additional transmission lines will be added shortly that more directly connect the two stations through the Wood Draw and Phantom substations.

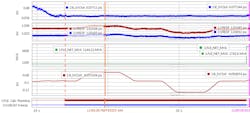

Advanced TSC Blocking

In the event of an unsymmetrical fault, the negative sequence voltage and overvoltage on one or more SVC bus phases trigger the SVC control to block TSC phases independently — unsymmetrical blocking — to reduce the resulting overvoltage. Once the fault is cleared, the negative sequence levels reduces and normal TSC control is released. Symmetrical blocking recognizes the moment of fault clearing and subsequently blocks all TSC phases for approximately 10-ms. This action enables the SVC to support the voltage during the fault while reducing the subsequent overvoltage that can occur immediately following fault clearing. As the fault diminishes and the negative sequence voltage reduces, the TSC control is released and the SVC returns to normal.

More Strength and Stability

SVCs and other dynamic shunt devices have become popular with transmission planners for solving stability and dynamic voltage control problems. Accordingly, these devices are being installed closer in proximity and interact. For standard voltage control, the interaction is accounted for using the slope settings. With special functions, like FLE, the interaction must be considered and coordinated in either the tuning of the function or communication between the stations. The results from the Roadrunner and China Draw SVCs using communication between the stations provide a good baseline for evaluating alternative solutions.

The transmission system sensitivity to an SVC admittance regulator control largely depends on the system fault level. When the SVC is small in relation to the system fault level, interaction between the regulator and system is usually not a concern. The challenge with a weak, heavily shunt-compensated transmission system — where the size of the SVC capacitive range approaches the system fault level — is the oscillatory frequencies show up in the range of interaction with the SVC controls. Advanced control and coordination in combination with a flexible SVC topology greatly increase operability of large SVCs in weak transmission systems. SVC adaptability to changes in the prevailing system fault level is key in this respect.

Between 2016 and 2020, the suite of Power for the Plains projects in southeast New Mexico resulted in the short-circuit MVA to increase 500%. The Phantom substation will soon connect China Draw and Roadrunner, providing a redundant fiber path and further increasing interaction between the sites. The fiber is expected to be installed soon and will enhance security of the FLE functionality between the two SVCs.

Martin Cameron has a BSEE degree from the Colorado School of Mines in Golden, Colorado, and a master’s degree in engineering management from the University of Colorado at Boulder. Currently a principal substation electrical engineer with Xcel Energy Inc., he has over 25 years of experience in hydro generation, substation protection and substation controls. In 2014, he started his involvement with flexible ac transmission system (FACTS) projects and has successfully completed a static VAR compensator (SVC) protection and controls refurbishment and two new SVC projects, all in New Mexico. With the two new SVC projects in New Mexico, an advanced control function was implemented between the two SVCs.

Anders Boström is with Hitachi ABB Power Grids in Raleigh, North Carolina, U.S. He received his MSEE degree from Chalmers University of Technology in Gothenburg, Sweden, in 1991. Boström joined ABB in 1992, where he was focused on the design and development of large frequency converters for power supply and drives. In 1998, he joined the ABB flexible ac transmission system (FACTS) department, where he has been responsible for system studies and the design of series compensation and utility FACTS equipment such as static VAR compensators (SVCs), static synchronous compensators (STATCOMs) and thyristor controlled series compensators (TCSCs).

Joe Warner received his BSEE and MSEE degrees from Wichita State University in Wichita, Kansas, U.S., in 2004 and 2005, respectively, after which he joined Hitachi ABB Power Grids in the field of power systems. After starting in corporate research working on distribution automation and multi-terminal high-voltage dc modeling, in 2008 he joined the flexible ac transmission system (FACTS) business supporting tenders, projects and upgrades for static VAR compensators (SVC), fixed series compensation and static synchronous compensators (STATCOMs). His experience ranges from pre-tender system studies, system design, factory acceptance testing, commissioning, customer training and failure investigation.