In recent decades, the growing need for electric power has brought out the need to implement increasingly efficient and reliable automation and protection systems for electrical substations. The development of remote control and tele-conduction functions, which supports remote management plant, has also become a fundamental requirement in the operation of the electricity network.

S.A.S. (Substation Automation Systems) are the new generation systems that perform the functions of protection, automation, control and which are designed based on the functional requirements of the IEC61850 Standard, having quickly become a key component of the energy transmission system.

With the introduction of the IEC61850 Standard, in fact, we have gone from engineering the functionality in the electrical substation through electromechanical systems to the adoption of architectures operating with standardized sets of protocols on high-speed LANs. This step, also, made the homogeneity of the functionality of each single station possible, until that moment operating with proprietary solutions potentially different from each other. A non-negligible merit of IEC 61850, for this reason, was that of laying the foundations for interoperability between devices from different suppliers.

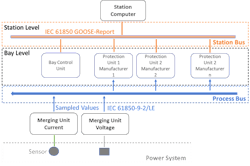

Thanks to the use of high-speed network technologies inside the substation, it was possible to develop the "Process Bus", defined and regulated by IEC61850-9-2 and IEC61850-9-2LE, for the transmission of measurements to the equipment of monitoring and protection through digital protocols. The centrality of transmission networks has, also, imposed the evolution of redundancy techniques aimed at strengthening the LANs on which an increasing number of information ‘travel’.

In this respect, this article aims to highlight the importance of interoperability in the adoption of the process bus for the communication of the Merging Unit with the Protection Units and the advantages of the redundancy of the communication network using the Parallel Redundancy Protocol (PRP) and Highly-available Seamless Redundancy (HSR).

With expertise based on several decades of R&D and field experience in protection and control systems, CESI Group is fully qualified to offer services to meet the needs of verification and assessment of systems and interoperability tests in this process of modernization.

CESI is a world-leading technical consulting and engineering company in the field of technology and innovation for the electric power sector. Through its Division KEMA Labs, CESI is the world leader for the independent Testing, Inspection and Certification activities in the electricity industry. With a legacy of more than 60 years of experience, it operates in 70 countries around the world and supports its global clients in meeting the energy transition challenges.

Aspects of Interoperability in the Use of the Process Bus

The Merging Unit (MU) is an essential building block in SAS systems. A MU acquires current and voltage signals from various transformers, converts them into digital form and through the process bus sends them, as sampled values, using process bus, to protection and monitoring equipment, often from different manufacturers.

In the implementation of this digital solution the definition of a structured test process in the following tasks is fundamental:

- System Integration: testing and verifying the correctness of the configuration of the devices involved in the communication, of the engineering of the IEC61850 profile and of the interoperability of devices from different manufacturers;

- Functionality: single device protection setting, timing, zone reach testing, communication testing, interlocking testing, verification of the reaction times of the protections after fault events;

- Performance: definition of performance evaluation criteria and of the performance evaluation in terms of latency delay in data transmission, priority handling and single/double point of failure test, interlock testing.

In regards to the interoperability between high voltage optical sensors, merging-units and distance protections of the high voltage line (HV), an ad-hoc LAN is used with two distinct sections: Process Bus, on which the SV generated by the MU transit, and Station Bus, for sending the information (GOOSE and REPORT) to the substation server. In this context, some of the checks that can be made are the following:

Measure Verifications of the Protections

In order to verify the correct behavior of the optical measurement chain [optical sensors - MU - Protections, with generation of sample values] and more generally of the measurement functions of the protections under test, some preliminary tests are normally performed in stationary conditions; voltages and sinusoidal currents at 50 Hz constant in module and phase, conditioning signals (logic inputs) constant with standard values. Each test results without "fault events" and has the purpose of verifying the congruence of voltage and current measurements (and related phase shift angles) at different levels (including short circuits).

In relation to current measurements with optical sensors, it is important to verify some fundamental results, such as i.e.:

- the current sensors must be substantially insensitive both to the possible centering of the current conductors and to the greater or lesser uniformity of the distribution of coils around the coils of the sensor itself;

- the current sensors must not have interference between the phases;

- the values coming from the MU must be read in a congruent way by the protections of different manufacturers.

Check on the Time Synchronization System

The synchronization of the devices is an important aspect, not only for the respect of the requirements defined in the IEC61850-5-2LE: in fact the tools used for the tests, the MUs, the circuits implemented with the respective technologies must be synchronized by the same source of synchronism to allow comparison between the test results.

Verification of the Correctness of the Data Flow

- In conditions of absence of perturbations in the field measurements (rest condition) it is important to verify that the communication network allows the normal circulation of SV, GOOSE and Report, in the dedicated network segments;

- Verify that the data flow out of the MU complies with the IEC61850-9-2/-2-LE standard.

The Redundancy of the Communication Network Through the Use of the PRP and HSR Protocols

Communication requirements in substations are evolving to support advanced applications based on "mission critical" messages, including for example the execution of "fast" protection and control commands. In this scenario, network redundancy becomes a crucial implementation aspect and must be designed to ensure adequate recovery times for mission critical functions in the event of failure. In this sense, networks based on classic redundancy via RSTP protocol may not provide transmission reliability.

IEC 62439-3 responds to this need by defining two protocols that provide near zero recovery time: PRP and HSR.

For most communications in substations, such as that between field devices and station SCADA, a recovery time of hundreds of milliseconds is adequate while for messages, for example, lock or unlock, based on GOOSE or SV messages, this time is high. A "mission critical" message must be received within the time limits included in the milliseconds interval because it would be compromised the protection functions.

The goal of implementing a redundant network is to ensure a timely packet delivery for various applications. The IEC 62439-4 standard defines the parallel redundancy protocol (PRP) and the IEC 62439-5 standard defines high availability seamless redundancy (HSR). Both with 0ms fail-over time, as required by critical high-speed functions with no packet loss. Two independent network interfaces present on a single device transmit the same data at the same time, the redundancy monitoring protocol ensures that the recipient uses only the first data packet and discards the second.

The concept which PRP is based on is the dispatch of two copies of each frame on two redundant hardware paths that can also be different in terms of performance and topology; PRP is implemented in end devices, while switches in networks are standard switches Ethernet. The PRP unit sends a message to the network through both ports at the same time, these two messages pass through the two independent networks unto the PRP unit, the latter manages the first packet and discards the second.

Unlike PRP, HSR is designed for use in ring topologies. The basic principle is to send identical frames in both directions around a ring. This ensures that a copy of the message will arrive at its destination, even if the ring is broken. Using two network ports, an HSR connection incorporates a double node that connects the two interfaces to form a ring. Each HSR node receive all frames that are sent only to it. Multicast and broadcast messages are relayed by every node in the ring. To prevent these messages from circulating forever, the node that initially send the message over the ring will remove it when return to him.

In the case of a failure, a frame will be sent by using of network in operation. In this way we have the redundancy with zero switchover time.

Process Bus and LAN redundancy protocols are two of the main solutions that represent the evolution of digital technology in new generation electrical substations. The challenge that awaits the Transmission System Operators (TSO) is to implement such solutions, fully exploiting their potential and ensuring complete interoperability between the devices involved. This can only be achieved through design and testing processes appropriate to the challenge.