Salt River Project Engineering Team Delivers Customers a Triple Play of Savings, Service and Quality with the Southern States CapSwitcher®

“The CapSwitcher® has delivered SRP-documented, system maintenance savings. Southern States has proven to be a reliable long-term partner to SRP, and we’re looking forward to building on our relationship with applications of the CapSwitcher and RLSwitcher at higher voltage levels.” - Andy Keels, Salt River Project, Professional Electrical Engineer

Salt River Project Background

Founded in 1903, Salt River Project (SRP) is one of America’s largest public power utilities. It provides electricity to around a million customers in a 2,900-square mile service area that spans three central Arizona counties, including most of the Phoenix metropolitan area. SRP is an integrated utility, providing generation, transmission and distribution of power. In recent years, SRP has experienced tremendous growth and this has served as a catalyst for power delivery infrastructure development, including significant transmission investment.

SRP’s planning incorporates their commitment to meet the changing needs and expectations of customers. Ahead of the 2017 fiscal year, the utility adapted a new strategy centered around becoming “leaner, greener and more customer centric.” The approach aims to keep maintenance checkup costs down for customers. SRP’s greener strategies, including the EarthWise EnergyTM program and renewables initiatives, focus on developing solutions that are both environmentally sensitive and affordable. The customer-centric strategy also strives to deliver the ultimate customer experience, through features like mobile accessibility, community involvement and online service options.

The initiatives build on SRP’s proactive systems investments over the years to serve rising new customer numbers and resulting load expansion across the Salt River Valley. SRP has regularly upgraded transmission systems in response to new demand. This included the construction of new extra-high voltage transmission corridors starting in 2005, the same year that SRP and Southern States began their relationship for the application of special-purpose power switching solutions in specific applications across SRP’s 69-kV systems and beyond.

SRP’s Changing Reactive Power Needs Create Opportunity for Innovation

Andy Keels, SRP professional electrical engineer, explained, “SRP designed its T&D system decades ago to be very robust, and we continue maintaining that strong focus today.” While the robust design has mitigated SRP’s need for the widespread use of reactive power compensation devices in recent years, changing customer loads has created new system operation challenges for dispersed renewable generation.

Before exploring the potential of Southern States’ CapSwitcher®, SRP’s approach to the need for reactive power in its systems was met through a fairly typical utility approach. Keels said, “Historically, when we did have to add in a shunt capacitor bank or reactor bank, we just used a standard circuit breaker to switch it on and off.”

Professional Electrical Engineer Andy Keels with Salt River Project’s latest 69-kV, 40 kA CapSwitcher®, located in a residential area.

Changing load patterns and an increasing need for more regular reactive power switching operations altered the calculus for SRP, creating an opportunity to consider a new, more cost-effective approach. “We discovered that using this traditional approach to switch a reactor or capacitor bank was not ideal. It caused a lot more breaker maintenance and all those field engineering costs that go with it,” noted Keels.

During system reviews, SRP’s apparatus engineering team observed a troubling trend. “We started experiencing more electrical and mechanical breaker failures due to either restrike or pre-strike, depending on which type of reactive component we were switching,” said Keels. Subsequent reviews revealed that SRP’s reactive compensation devices (capacitors or reactors) were increasingly being switched in and out of system, sometimes several times a day, by the SRP transmission operators.

The need to make adjustments to reactive power flow during the day has only grown over the years, as SRP has seen large data centers come online in locations that might not have initially been designed as firmly as other areas. Because these new loads draw large quantities of power from SRP’s system, SRP has continued investing in reactor and capacitor banks. SRP has also seen reactive power needs grow from increasing penetrations of renewable generation, including solar, with power flow now occurring in different directions and ways than SRP’s transmission network was originally designed for.

Under its ongoing Capital Improvement Program, SRP focuses on continuous improvements in efficiency and reliability with the existing, planned and future systems for generation, transmission and distribution. Starting in 2005, SRP began validating the savings, operational and customer service improvements possible from the application of the Southern States’ CapSwitcher® and RLSwitcher®.

CapSwitcher® Delivers

Over time, SRP’s leaders realized they needed an entirely different and more cost-effective approach to its reactive power switching needs. Keels explained, “In the past where we used to put a breaker in and just take a maintenance hit, we now knew we couldn’t continue to put standard, multipurpose breakers in an application that required high-maintenance breaker devices. Instead, we needed to come up with a smarter solution.”

Salt River Project installed Southern States’ CapSwitcher®, a switch designed specifically for switching shunt reactors.

To meet these evolving needs, SRP installed Southern States’ CapSwitcher® in dozens of locations across its 69-kV system. As of early 2019, new deployments at higher voltage levels were also underway. Keels cited Southern States’ innovative design and cost-effectiveness as factors in SRP’s decision to expand their use. “We determined the best approach for us is to deploy devices that are specifically designed for switching applications where the voltage and current are not in phase.”

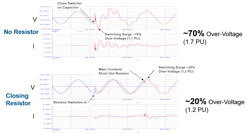

The CapSwitcher’s use of a closing resistor significantly reduces inrush current, eliminating the need for the inrush current reactors often required for use with breakers and other switching devices. The patented solution incorporates closing resistors that minimize voltage and current transients, as well as a simple mechanical design rated for more than 10,000 operations.

In addition to delivering maintenance savings and improved power quality, the CapSwitcher® has even provided relief for an SRP substation noise concern from a nearby neighborhood. Keels recalled, “There was one situation where we were using an open-air type switching device. It was a rather complicated disconnect switch with an attached interrupter device. The audible noise and bright flash it made every time it switched was disturbing a nearby subdivision.” SRP conducted a sound level study and discovered that the Southern States CapSwitcher® was significantly quieter than their deployed device. SRP solved the problem by deploying a CapSwitcher® in a nearby substation, effectively resolving the disturbance and ensuring customer satisfaction.

SRP implemented the CapSwitcher® after a local neighborhood complained of loud noises and bright flashes coming from the previous, open-air type switching device.

Reliable Switching for Solar

To achieve its goal of adding an additional 1 GW of utility-scale solar power to their grid by 2025, Salt River Project will be increasingly reliant on the Southern States CapSwitcher® and RLSwitcher to ensure power reliability to end-customers.

SRP’s experience may provide a model to other utilities that increasingly rely on sustainable sources like solar power. With states like SRP’s neighbor California continuing to incentivize electric utilities to incorporate PV generation, local power systems may become overwhelmed by the increased demands of trying to switch devices in and out of their systems. Switching these reactive compensation devices can create transient, which in turn can cause solar inverters to be tripped off the grid.

The Southern States CapSwitcher® mitigated SRP’s noise and sound complaints, as well as increased end-user reliability by minimizing switching transients.

Southern States’ CapSwitcher® device addresses one of the solar industry’s most pressing issues by significantly reducing switching transients to prevent any trips or outages. As solar-related DERs continue to populate the grid, utilities must be confident that their systems are equipped with the most secure and reliable equipment.

Proven Switching Solution

Keels explained that SRP has found that the old approach of using traditional switching devices -- which attempt to predict the current zero and switch at that instant -- works inconsistently, raising safety and connection concerns. “Playing a game of chance with shunt capacitor banks near a hospital or critical manufacturing business can have considerable consequences. The Southern States CapSwitcher® and RLSwitcher® devices provide us with a switching solution that delivers consistent results every time they switch,” Keels concluded.

Tom Speas, Southern States vice president of marketing, said, “We look forward to continuing our productive relationship with SRP to help ensure reliable and cost-effective power to their growing customer base.” Keels added, “The CapSwitcher® has delivered SRP-documented system maintenance savings. Southern States has proven to be a reliable long-term partner to SRP, and we’re looking forward to building on our relationship with applications at higher voltage levels.”

For more information on this solution, download Southern States’ Capacitor Switching Bulletin.

Sponsored By: