Drone Inspection Pinpoints Issues on Overhead Lines

As the second largest cooperative in the nation, Middle Tennessee Electric manages more than 225,000 meters and 12,000 miles of energized line. The cooperative distributes electricity to about 212,000 residential and business members in a large and diverse four-county area just south of Nashville, Tennessee.

With many of the wood poles in the subject inspection area towering at more than 70 ft tall and nearing or exceeding 30 years old, Middle Tennessee Electric focuses on regular ground inspections to identify any issues that could affect reliability. As such, conducting an overhead inspection in this rural area poses a significant number of challenges. To access these structures, the company invested in specialized bucket trucks, but it only has a few of these vehicles within its fleet.

Inspecting Infrastructure

Recently, the company took a time-saving approach by partnering with Preformed Line Products (PLP) Inspection Services to conduct a comprehensive aerial inspection of 1500 structures with drone technology. By flying above and alongside Middle Tennessee’s infrastructure, drones were able to capture thousands of high-resolution images and vast amounts of data to help detect reliability concerns.

Done the conventional way, the overhead line inspection would have taken 18 months to two years. Because it would take the crew longer to set up the bucket truck than to do the actual inspection, this approach would have been very labor-intensive and time consuming. For example, some of the area was located near a busy area of the city, requiring flaggers to provide traffic control. In just a few weeks, however, PLP Inspection Services was able to complete the project in Woodbury, Tennessee, using drones.

Identifying Problems

By using drone technology, the team could get a better visualization of the equipment including transformers, insulators and splices. PLP Inspection Services’ uses several types of drones to collect data, including a dual vision (two-camera) drone that captures high-resolution electro-optical images and infrared imagery in the same flight. Using high-resolution first-person view goggles, PLP’s onsite engineers get a drone’s-eye view of the inspection as it occurs.

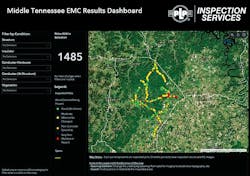

The PLP Inspection Services crew consists of a pilot, a safety observer and a field engineer. The industry experienced field engineer from PLP worked with a utility lineman to identify major reliability concerns during the on-site inspection process and immediately reported the information to Middle Tennessee Electric’s team. PLP also provided an Inspection Dashboard, which allowed the cooperative to monitor inspection progress in real time.

A PLP Inspection Services drone collects images near one of the 1485 structures analyzed during the MTEMC inspection.

As an added safety measure, PLP Inspection Services pairs a visual observer (a person dedicated to continuously monitoring the drone’s path) with each drone pilot.

Initially, the group found such issues as hollowed-out poles from woodpecker damage and bolts hanging by the outside of the poles. Also, the drone images revealed chipped insulators, fungus growth on top of the poles, water egress and pole top rot and split crossarms. To discover hot spots, PLP used high-tech infrared cameras, which could find loose connections on devices and splices that had issues.

The drone inspection discovered severe rot on the top of a pole.

From the ground, it would have been nearly impossible for the linemen to detect these issues. Instead, they would have to set up the specialized truck to get high enough to spot these problems.

Analyzing Images

Following drone inspections, utilities are often left with thousands of images and no specific way to analyze and categorize them. However, one of the biggest advantages of partnering with PLP was the turnkey service they provide. As opposed to Middle Tennessee Electric wading through the vast amounts of data on their own, PLP provided them with the complete analysis and recommendations, a standard feature of the company’s Level 1 inspections. This saved the utility an immense amount of time and effort while also allowing it to better use its own resources.

To help Middle Tennessee Electric categorize the work orders, PLP’s engineers and subject matter experts in Cleveland, Ohio, first reviewed the images to look for anomalies. Next, they drew from PLP’s 70-plus years of utility industry knowledge and product testing experience to classify the images and assign each component category a rating. Finally, PLP’s GIS Analyst created an interactive map of the service territory with color-coded areas so Middle Tennessee Electric could prioritize work around specific locations and infrastructure assets.

Customers can view color-coded results at a glance with PLP’s Results Dashboard.

In addition, PLP recorded all of the issues on a spreadsheet and provided a detailed report complete with executive summary, explanation of trends, and examples of common reliability concerns observed. Additionally, all images captured during the inspection were cataloged by structure and delivered to Middle Tennessee Electric. The utility can then easily archive the thousands of images for future reference.

Taking Action

Typically, Middle Tennessee Electric has a six-year maintenance cycle, but as a result of the recent drone inspections, the company worked the pressing issues into its work plans. Based on the recommendations and ratings from PLP, Middle Tennessee Electric prioritized the tasks by ranking them from minor to critical. For example, some issues wouldn’t cause an immediate failure and could wait a year or two to resolve. Others, however, could cause an imminent failure if not addressed immediately.

Throughout the company’s service territory, four linemen are responsible for the overhead maintenance of Middle Tennessee Electric’s system. The company has four main area offices, and each area office has four to six crews of four to five linemen. In addition, three support engineers and two designers work with the field team to identify and solve problems in the field.

When working on these work orders, the linemen can pull up photos of specific poles on their iPads through the work management system. That way, they can more easily visualize the issues and devise a proper plan of action. For example, the Explorer app for ArcGIS allows field crews to access the inspection map from their mobile devices.

In the future, the company may expand the use of drone inspection services to other parts of its service territory to save time and labor hours for its field and engineering teams. By using drones and partnering with a company like PLP, the utility can efficiently inspect its infrastructure in remote locations or even in logistically challenged areas like busy neighborhoods without shutting down traffic.

Sidebar: By the Numbers: Drone Inspection

- 1485 structures analyzed

- 231.7 GBs of data collected and analyzed

- 36,449 images collected

- 303 reliability concerns found

- 77 miles flown by the drones

- 621 drone flights

Company Listings:

Middle Tennessee Electric | www.mtemc.com

Preformed Line Products | www.preformed.com