Statnett Tackles Extreme Ice Loads in Norway

Statnett faces many challenges familiar to transmission operators worldwide, but Norway’s unique environment brings its own set of extreme difficulties. Transmission lines in mountainous areas bear some of the heaviest ice loads on the planet; in 1961, an unofficial world record of 305 kg-m (205 lb-ft) was recorded at Lønnahorgi, as Statnett shared at its 2019 R&D conference. Many of the country’s transmission lines traverse vast, mountainous terrain, cross long fjords and endure relentless winds—all of which create ideal conditions for conductor icing.

This combination of high mountains, windy conditions and expansive fjords requires the adaptation of innovative solutions that ensure both safety and reliability. Ice buildup can lead to line failures, costly repairs and significant risks for crews and linemen working in dangerous conditions. Ensuring network stability and reliability requires prioritizing the prediction, reduction and mitigation of ice loads, particularly given the anticipated increase in ice accumulation due to ongoing climate change.

Rugged Monitoring

In 2013 and 2014, Statnett experienced heavier ice loads than predicted on parts of its transmission system, as shared at the 2015 International Workshop on Atmospheric Icing of Structures event in Uppsala, Sweden.

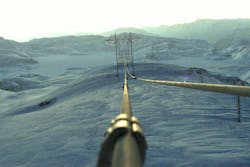

After testing several solutions for monitoring ice accumulation over the next few years, most were unsuitable due to the rugged conditions in which Statnett operates. However, one solution showed promise. In 2020, the utility launched a pilot project using technology from Laki Power at Ålvik Mountain in northwestern Norway, situated 1000 m (3281 ft) above sea level. This location experiences particularly severe ice loads and access is challenging, especially during adverse weather.

Laki Power’s LKX-203 system, now rebranded as the LKX-MULTI, features three ultra-high-definition cameras along with a suite of environmental and line sensors. The cameras provide continuous, real-time visual monitoring and video recording of spans, towers and ground. The accelerometers and wind sensors enable the calculation of ice loads and assessment of environmental conditions before deploying helicopters to deice lines during challenging weather.

One of the most cost-effective aspects of the remote line monitoring system is its power-harvesting technology. By drawing energy directly from the transmission line, it eliminates reliance on diesel generators and other external power sources. Installation consists of inserting the correct inlays for the conductor at hand and closing the lid.

Real Results

Before implementing the surveillance system, Statnett relied on load cells for ice load measurements as the sole input for scheduling deicing work. However, these devices provide only a limited, single data input, making it difficult to get a full picture of the ice type and condition of the line during an icing event. With the rugged remote line monitoring system installed, spans, load data and local weather conditions are now monitored in real time, enabling visual assessment of ice buildup along the conductor. Understanding the type of ice—whether it is in-cloud icing, rime icing or another variety—enables Statnett to create specific strategies to prevent additional buildup.

Through this collaboration, Laki Power enhanced its Analytics Studio, adding an ice overlay feature based on input from Statnett. This feature allows direct measurement of the ice diameter, critical information that gives Statnett an even clearer understanding of conductor stress and time to organize deicing with the helicopter well in advance of potential failure.

In the past, deicing involved sending helicopters out three times to four times each winter. This was a costly and carbon-intensive process, often resulting in wasted trips back to the base due to adverse weather or foggy conditions that prevented work from being done. Thanks to the system’s real-time visual monitoring, helicopter deployments are now limited to fly-ready weather conditions, reducing both operational costs and environmental impact.

The pilot also revealed unanticipated risks. In one instance, the system alerted the utility to line galloping, an oscillation caused by wind and ice that can damage lines over time. With this real-time insight, Statnett was able to address the issue and plan more effectively for maintenance and mitigation. Additionally, corona discharges observed both during and after a storm indicated potential conductor damage, prompting the utility to schedule proactive maintenance.

Ultimately, the project exceeded initial expectations, providing valuable insights into line health and environmental conditions. As a result, the utility decided to purchase several units. The system’s ease of installation and removal allows Statnett to move the units to the most beneficial locations as needed.

Building on the pilot’s success, Statnett is continuing to collaborate with Laki Power to unlock even more value from the autonomous monitoring system. Using data and images collected during the pilot, work is underway to develop an AI forecasting model that will predict the likelihood of icing or galloping events up to 24 hours in advance.

Some of the units will be relocated to new sites after collecting sufficient data to support transmission design teams. A crucial next step is testing live-line installation, which would eliminate the need for scheduling outages and simplify the process of moving units where they are most needed. This system has not only strengthened Statnett’s operational capabilities but also paved the way for preventing failures, marking a significant leap toward more reliable and proactive grid management.

About the Author

Arild Berstad

Arild Kvamme Berstad ([email protected]) graduated from Bergen University College while working as an electrical engineer in Statnett SF’s transmission line department. As a senior engineer, he is committed to the maintenance of existing transmission lines, ensuring the lights stay on. Berstad is cited as the main author of the CIGRE paper, “Electrical Design and Testing of Composite Towers for 420 kV,” which received a Best Paper Award during the CIGRE 2020 e-session.