Commonwealth Edison Co. has been conducting circuit-level, four-year, cycle-based vegetation management for more than 18 years. During this time, the utility has seen an overall downward trend in vegetation-related interruptions and best-on-record vegetation reliability metrics. These findings suggest circuit-level, cycle-based vegetation management (VM) has been successful for the utility over the first four full cycles. However, increasing reliability goals as well as budget challenges associated with VM are driving many utilities, including Commonwealth Edison (ComEd), to explore new technologies and methods to reduce costs and tree-related interruptions.

ComEd’s tree trimming contractors (TTC) are engaged with per-circuit-mile rates on a regional basis. Trees are trimmed to achieve specified clearance distances, which can create variability in the TTC’s workload depending on tree species and canopy density. For example, TTC are paid the same cost per mile whether a mile is dense woods or a mile of farm fields. During the bidding process, the potential TTC should field-inspect as much of the system as possible and supply a cost-per-mile bid that accounts for all trimming needs.

ComEd services the northern one-third of Illinois — including Chicago, the third largest city in the U.S., with a distribution system covering nearly 35,000 circuit miles, from dense urban communities to rural farm fields. It can be challenging for TTC to supply accurate rates that truly account for all the variabilities on the system. Because of the uncertainty of the work, TTC may incorporate additional costs within their bid to safeguard against the unknown.

Remote-Sensing Technology

Crew allocation needs are often a challenge because of the variability in work scope. By historically being on a cost-per-mile contract, ComEd does not possess the data to estimate workload per circuit. Although an average work scope can be created per circuit mile, the differences between work per circuit, or even span, can fluctuate, resulting in variable workforce needs. Crew needs do not directly impact a utility financially on a cost-per-mile contract, but they can be indirectly affected if the TTC struggle with meeting staffing levels.

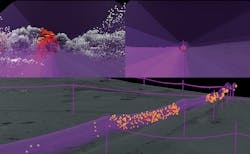

Light detection and ranging (LiDAR) is a remote-sensing technology that uses pulsed laser light to characterize objects and locate them in 3-D space. LiDAR’s remote-sensing technology has been used in transmission VM for more than a decade. It has proven to be a beneficial tool for identifying vegetation around utility infrastructure by providing accurate geographical representation of objects on the earth’s surface. As the technology has evolved, LiDAR collection costs have decreased and, as a result, LiDAR for distribution VM is beginning to surface as a feasible option to capture vegetation surrounding the distribution system.

In addition, hyperspectral imagery (HI), a relatively new technology in utility VM, is a remote-sensing technology that characterizes individual tree species and health data on a large geographical scale using fixed-wing or rotary-wing aircraft. A better understanding of species composition for the entire system is valuable information because tree growth rates and likelihood of causing an outage can be correlated to species.

Pilot Work Scope

ComEd conducted a pilot study in the summer of 2017 to examine the viability of LiDAR and HI for distribution VM, with a focus on capturing vegetation density, species, and health and generating future work scope. The theory was LiDAR data could be used to restructure future line clearance contracts from circuit-mile pricing to a more precise work-scope contract, such as linear trim distance or unit based.

Four distinct geographic zones were selected for the pilot to capture the diversity of ComEd’s service territory. The northeastern/central eastern (NE/CE) zone represented a suburban area with forest preserves and dense-tree canopy. The Evanston zone represented high-density houses with mature trees and alleys. The southeastern (SE) zone represented a high-density urban area with weak-wooded tree species and alleys. The northwestern (NW) zone represented a low-population rural area with agriculture and sparse tree density. In total, the pilot area coverage was approximately 2.5% of the service territory based on circuit mileage.

The pilot used LiDAR acquisition through fixed-wing aircraft to mimic a full system acquisition. LiDAR acquisition began in June 2017, with processed data available by the end of July 2017. ComEd gave LiDAR vendors an opportunity to showcase additional deliverables, but the overall minimum deliverables requested were as follows:

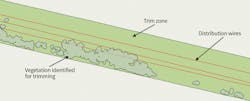

- Post-processed LiDAR data set in a standard ESRI-based geographic information system (GIS) format, classifying utility poles, distribution lines, foliage volume, tree crowns, tree locations relative to distribution lines, buildings and surrounding obstructions as well as their proximity to distribution lines.

- HI acquisition and analysis for tree species and health.

- Any proprietary software required for viewing.

Five vendors were interviewed and invited to submit bids. An evaluation scorecard was developed to rank the vendors based on criteria such as technical experience (distribution VM specific), command of project, technical abilities, deliverables and pricing. Two vendors were selected. Vendor A conducted LiDAR and HI acquisition for NE/CE and Evanston, while Vendor B conducted LiDAR and near-infrared acquisition over all four zones.

Field Data Collection

Vendor A delivered all requested data from July 2017 to September 2017. Vendor B was only able to supply partial deliverables through December 2017, at which point its contract was renegotiated and closed because of time limitations.

Field reviews were conducted by ComEd as a quality assurance check of the data. Vendor B had several locations where the circuit configuration was incorrect. In areas where both vendors flew, a side-by-side comparison was conducted. There were several areas where Vendor A correctly mapped the circuit but Vendor B did not. It is believed the vendor’s proprietary algorithms for mapping infrastructure were the cause of the errors. One common error by both vendors was interpretation of conductors where neutral wires ran at the same height as primary conductors. For example, if a single phase ended at a pole but a neutral wire continued for another span at the same height, the vendors incorrectly identified it as a continuation of the primary. Interpretation of conductors was the most common deviation found in mapping infrastructure, so it is something to note for any future LiDAR acquisitions.

A range finder was used during the field reviews to measure vegetation and hard-surface clearances, which was then compared to the data delivered by the vendors. Overall, clearances were found to be accurate, considering two to three months of the growing season had occurred since initial data collection.

A field review of the tree health data was inconclusive. When reviewing Vendor A’s breakdown of health per species, it was found coniferous species had a higher percentage of unhealthy trees than deciduous species. It is believed using the same standardized health index for conifer and deciduous trees skewed the health classifications. Tree species through HI was found to be moderately accurate in the field, with an overall accuracy reported by the vendor as 78%.

Based on several years of outage investigation results, Siberian elm and silver maple are consistently ComEd’s top two outage-causing species. Therefore, additional focus was placed on ensuring these species were identified correctly. A confusion matrix was prepared for the NE/CE zone. It illustrates the producer’s accuracy, which is the validation of a known data set, and a user’s accuracy, which represents the field classification accuracy. Siberian elm had a user’s accuracy of 93.3% and a producer’s accuracy of 82.4% while silver maple had 74.4% and 98.3%, respectively.

Volumetric Pricing

The initial concept for the pilot was to use data to develop a linear trim distance or unit-based contractual structure. The limiting factor with linear trim is that it only considers one dimension of vegetation; however, trees may surround power lines from above, the sides and underneath. Because LiDAR can capture a 3-D product, trim volume (cubic feet) was developed as a concept to be explored.

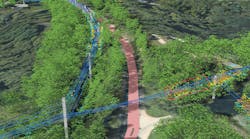

ComEd asked the vendors to submit volumetric calculations for each of their pilot areas. Volume of vegetation was calculated within a 10-ft radius of the distribution lines, as 10 ft is the average clearance distance required at ComEd during cycle maintenance. A 3-D display of the LiDAR data with vegetation encroachment around the distribution lines was prepared. A red cylinder outline was added to the image to assist in visualizing the 10-ft trim radius around the lines.

Once the volumetric data was received, ComEd sent experienced TTC out to specified areas within the NE/CE, NW and SE pilot zones to calculate manual and lift tree crew hours that would be required to trim the area to cycle-trim specifications. Specified areas within three of the four zones were selected, rather than each zone in its entirety, because of time limitations. The estimated hours supplied by the TTC were converted to a total cost per specified area using current time and equipment (T&E) rates.

The total costs were divided by the LiDAR volume in the specified areas to develop a regional cost per cubic foot ($/cu ft). The $/cu ft was applied to all pilot areas and compared with the four-year average regional $/mile rates. A potential gross savings of 5.4% was calculated using this method.

Two key benefits of volumetric pricing beyond the potential savings already noted were work-scope generator and potential increased bid competition. If a baseline can be developed for hours/cu ft and LiDAR is flown for the circuits in the cycle, then work scope and crew needs can be identified on a per-span basis for an entire cycle year. In addition, if volumetric data was supplied during the bid process, it would create a consistent and comparative arena, so all potential TTC would receive the same work scope rather than basing rates solely on walking down a portion of the lines or existing TTC using historical data. Increased bid competition results in increased competitive pricing. Having an exact work scope included during the bid also would eliminate or reduce the risk TTC build into their pricing. Possessing the exact work scope also would benefit the utility in contract negotiations.

Next Steps

Overall, the pilot confirmed LiDAR can capture tree proximity to distribution wires with high accuracy. Vendor A had a relative accuracy of 6.6 cm with an average of 31.33 points per square meter (PPMS). All trees within striking distance were identified individually, with proximity to wires, tree health and species. Knowing vegetation densities, species composition and health can be used for storm-damage predictability and reliability-based VM programs. Another benefit was identifying all stacked circuits, whether two 12-kV feeders or a 12-kV and 34-kV on the same pole.

Under ComEd’s current contract structure of cost per circuit mile, TTC are paid per-circuit-mile regardless of whether the circuits are on the same pole. LiDAR identifies all stacked feeders and vegetation information around them, so a revised contract structure using this information could be developed with potentially significant cost savings.

Non-vegetation measurements delivered during the pilot included wire to ground, wire to wire, wire to structure, span length, pole height and georectification of utility assets. These measurements combined with vegetation data supply additional benefits such as validating and prioritizing line clearances for maintenance inspection, validating engineering solutions for poor performing circuits and identifying third-party pole attachments.

ComEd’s plan is to conduct a phased implementation of distribution LiDAR to develop the concept of volumetric pricing further and solidify identified benefits. A portion of 2020’s cycle trim circuits will be flown in 2019 to collect LiDAR data, including volumes. This data then will be analyzed through 2020, comparing actual trim hours with volume to develop a baseline hours/cu ft. The data will be shared with TTC to help establish volumetric pricing as a recognized methodology.

In addition to volume, further investigation will be done on the other vegetation and non-vegetation benefits. Based on the pilot results, a future next step could be full-system implementation with new volumetric pricing contracts.