Tree Intelligence: FPL Controls Plant Life that Never Stops Growing

One of the most beautiful yet fragile landscapes in the continental U.S., Florida is a challenging landscape for electric utilities to manage as it combines thickly grown vegetation with an often-extreme climate that includes hurricanes, frequent thunderstorms and the downed trees that these severe weather events bring with them. For Florida Power & Light Company, using advances in technology to manage these demands is a key to delivering superior reliability to its customers.

The FPL service territory includes more than 85,000 miles of power lines in 43 counties spanning two time zones with many species of trees and vegetation. Perhaps the most daunting challenge FPL faces is the year-round growing season in Florida. In the Sunshine State, there is enough light, heat and moisture to ensure plants never stop growing. This may require more frequent data collection to properly capture changes in conditions. FPL is also working to make sure it can use the systems and data for hurricane response, leveraging digital twin technology against post-storm scans to assist with post-storm damage.

The more detailed data FPL can get about its infrastructure, including the vegetation which may impact it, the better it is able to serve the utility’s 5.7 million customer accounts supporting more than 11 million residents across Florida. Many utility vegetation programs rely heavily on visual inspections and are largely dependent on ground crews for vegetation management. Those utilities without visual intelligence generally prefer fixed vegetation trimming cycles and rely on pen and paper to manage their program. With a digital solution, they can make better, more informed decisions about where and when to trim vegetation.

Some utilities are opening up to changing their inspection processes and survey data portfolio as long as the new options allow them to maintain or improve reliability for less money. Over the last decade, LiDAR collection costs have decreased so utilities can accurately identify trees and risk and develop annual preventative and reactive work plans using analytics and AI.

FPL began using LiDAR for transmission lines in 2016 and expanded it to distribution facilities through a series of proofs of concepts late in 2020 and limited pilots in early 2021. The utility is currently working on expanding its use statewide.

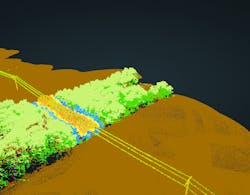

FPL paired with GE Digital to develop a platform that integrates GIS, LiDAR, and analytics to create a 3D digital twin and 2D GIS-style visuals and reports. The team also integrated the outputs into existing work management electronic workflows to optimize the field resources.

Before its work with GE Digital, FPL began transforming its program from one that relied largely on paper forms and notes in the field to a fully electronic workflow. The new process allows work to be scoped, scheduled and issued to a tree crew electronically. LiDAR laid the foundation for future remote sensing refinements. The process also allows FPL to use LiDAR and other data sources (RGB, hyperspectral, multispectral, FLIR, etc.) to refine and automate its work scope, which will further drive crew efficiencies and save inspection time. The system will also be interoperable with Electric Office, Smallworld, and GE’s ADMS, reducing time, complexity, and errors in data transfer & Integration. The utility can now make better decisions about where to trim and that ultimately benefits customers.

GE’s AI-based vegetation management system, called Visual Intelligence, has two components: data capture and vegetation management analytics. The potential value generated by using data-driven visual images captured by many different sources (drones, fixed-wing, helicopters, satellites, humans, sensors) to drive vegetation management decisions is based on this analysis approach:

- First, move from an annual rotational trimming strategy to a purely risk-based approach that identifies and categorizes overgrowth encroachment risk across the entire region. This approach drives the highest priority trimming in the current year and recognizes the uniqueness of the service area.

- And second, move from a distance-based vendor payment model to a volume-based payment model. This approach shifts payments from miles/kilometers covered to actual acres trimmed.

For FPL, the most significant benefit to the system is the ability to work in three dimensions rather than two. FPL historically planned work based on linear miles or footage, but all miles are not equal. The LiDAR data allows vegetation program managers to be more precise and efficient in assigning work.

Visual Intelligence takes a data-driven approach to vegetation management, asset inspection, and asset inventory using visual intelligence. Inspection data can be collected using a variety of means, including drones, fixed-wing aircraft, helicopters, satellite data, as well as thorough visual inspections. This data can be collected across a wide service area that will benefit some large electric utilities worldwide.

AI-based classification for LiDAR point clouds and photogrammetry allows automated classification of vegetation and trees in the area of interest. Machine learning automates vegetation growth calculations and 2D/3D dangerous tree maps and then produces risk-based trimming plans as shapefiles specifying trim prioritization, trim volume calculation, and ground clearance.

Automated analysis workflows allow personnel to focus on critical issues that require their immediate attention, spending less time and energy reviewing visual inspections datasets. By integrating the visual inspection data with the system of record, overlaying the data with the Geographic Information System (GIS), the utility gains essential context.

Using a data-driven approach to vegetation management is a significant factor in mitigating damage to grid facilities and avoiding weather-related outages and wildfires. GE Digital’s Visual Intelligence suite also allows utilities to deploy asset inspections across their territory to help with storm recovery, which allows for economies of scale and coordination of data.

FPL and GE Digital have also worked together in the microgrids arena. In 2021, FPL opened a Microgrid Control Lab at the University of Central Florida in Orlando, which serves as a research facility and offers computer and engineering students a chance to work in a utility control room.

Exploring and leveraging new technology to continuously improve service to customers is part of the culture at FPL. So, as the utility works to operationalize LiDAR for vegetation management, it is also mindful of how this technology can be used and adapted elsewhere. That includes working to tie the data in with asset management systems and make it available for a wide variety of utility inspections.