Photo by SDG&E.

Preventive Assessments

Typically, utilities send field crews to visually inspect equipment for damage, which can require significant personnel hours, increasing costs, the chance of worker injuries and the possibility of damaging the surrounding environment when driving or hiking through sensitive habitats. Utilities, including SDG&E, also have used helicopters, which also comes at a cost. Therefore, SDG&E sought approval from the Federal Aviation Administration to use drones for multiple use cases, including assessments. It was one of the first utilities to receive approval in 2014.

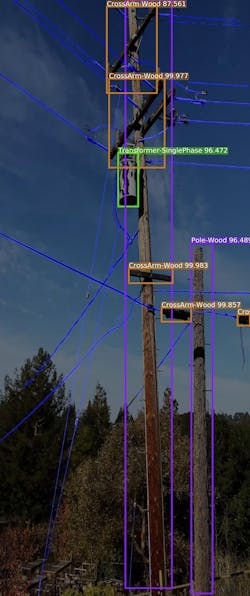

Intelligent Image Processing

After teaching the image-recognition models to accurately identify the equipment by tagging and confirming the contents of all 2.3 million photos, SDG&E’s team applied their experience to grading the condition of equipment. By adding the insights of experienced linemen upfront, the data and model became far more accurate when analyzing images. And if the technology is unable to analyze the images, the model sends them to qualified technicians for further review.

This technology enables the utility to quickly identify damage that could lead to ignition and helps it to prioritize and initiate work in the field to repair the equipment.The team built a map-based user interface to visualize and browse for imagery and machine learning results stored in the image repository. To facilitate continuous improvement and refinement of the models, a feedback loop was created within the platform, enabling qualified workers to validate machine learning results to optimize the model performance.

AI & Machine Learning Models

The multi-departmental team, together with the asset management and operations departments, has changed the utility’s approach to managing the immense electric infrastructure portfolio. Intelligent image processing is truly groundbreaking and promises to be a game-changer in SDG&E’s mission to mitigate wildfire risk, minimize outages for customers and ensure the safety of the communities it serves.