Integrate DLR and EEMS for a Future-Ready Grid

The U.S. electrical grid is a critical component of the modern economy, providing safe, reliable and cost-effective electricity to customers. However, it faces multifaceted challenges, ranging from the need to improve transmission capacity to addressing the escalating risk of wildfires. Offering a potential remedy to these challenges is the promising synergy of dynamic line rating (DLR) and engineered electrical mechanical shunt (EEMS) technologies.

With a history spanning more than 125 years, the U.S. electric power system is a sophisticated machine, intricately woven with generators, substations, towers, wires, transformers, switches and poles. With more than 240,000 miles (386,243 km) of high-voltage transmission lines and 5.5 million miles (8.9 million km) of local distribution lines, the grid operates within a mosaic of federal, state, tribal and local regulatory jurisdictions. The Federal Energy Regulatory Commission and North American Electric Reliability Corporation oversee the reliability of the bulk power system, but the challenges are diverse and evolving.

With a significant portion of the power system far exceeding 25 years, the aging infrastructure of the electric grid poses a looming threat to reliability. The transition from dispatchable to alternative generation sources adds layers of complexity. Transmission congestion, a concern where changes in demand or generation surpass a line’s electrical capacity, could lead to suboptimal energy commitments and dispatch of generators, escalating the cost of electricity. Traditional solutions entail substantial investments in expanding and upgrading transmission line capacity, which come with hefty price tags and extended lead times. Meanwhile, the intensifying frequency and severity of wildfires pose a considerable threat, especially to overhead electrical lines, necessitating innovative solutions for enhancing reliability and mitigating the risks of falling conductors.

Dynamic Line Rating

DLR is emerging as a transformative technology capable of reshaping the landscape of transmission capacity management. It engages in real-time assessments of the electrical capacity of transmission lines using actual weather condition variables, such as temperature and wind speed as well as measured conductor temperature. Unlike static line ratings that are intentionally conservative, DLR provides real-time understanding of a transmission line’s acutal loading capabilities, allowing for adding capacity above the static rating.

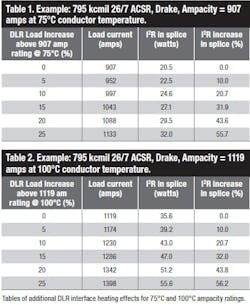

By continuously monitoring environmental conditions, conductor temperature, and adjusting line ratings accordingly, DLR facilitates precise control of the power transmission network. This is particularly crucial in regions with air temperature and wind variations, where static line ratings may result in underutilization during mild conditions or overheating during peak demand periods. It is important to note the additional current on the electrical interface of the connectors remains unaffected by wind or cooler temperatures. Neglecting to address the overheating of connectors due to higher loading from a DLR program could result in catastrophic consequences.

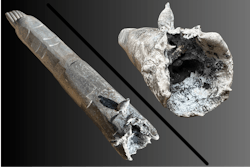

Transmission lines using aluminum conductor steel-supported (ACSS) conductor built before the year 2001 used mineral oil-based inhibitor, which itself has thermal limitations of 163°C (325°F) and leads to failed connectors. With age, these connectors deteriorate faster and fail sooner.

Scientific studies, industry standards and empirical evidence over the past 30 years provide the evidence that an increase in conductor current flow results in accelerated aging and connector degradation at the electrical interface, and ultimately result in earlier connector failure. Neglecting to address the impact on connectors in the process of adding DLR could lead to catastrophic failures, line-down incidents and unplanned outages.

The vulnerabilities inherent in the energized components of the transmission system, particularly connector failures leading to dropped conductors, underscore the urgency of implementing effective connector mitigation strategies. Typically occurring under tension, these failures result from the degradation of the electrical interface between connectors and conductors, leading to increased internal resistance and thermal runaway. The consequences range from electrical outages to potential wildfires from dropped conductors, posing significant risks to life and property.

Risk Mitigation

Mitigating these risks requires proven strategies to restore damaged and compromised components to their original or an improved condition, mechanically and electrically, without necessitating an outage. Additionally, assessing the life extension of aging overhead assets involves considering various factors, such as component condition, long-term plans, regulatory requirements and environmental concerns. Proactive measures like hardening the lines and implementing preventive maintenance are vital for enhancing resilience and reliability.

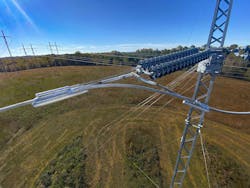

Enter EEMS, under the trade name ClampStar, a complementary solution designed to address the challenges of an aging grid. One of the pivotal features of EEMS is its dual role in restoring mechanical integrity to dead ends, splices, joints, suspension clamps and systems while restoring the electrical ampacity of a line. This dual functionality marks a significant leap forward, considering electrical capacity limits often hinge on the thermal capacity of connector-conductor systems.

The amalgamation of DLR and EEMS technologies presents a holistic solution to the multifaceted challenges faced by the U.S. electric grid. By integrating real-time assessments of transmission line capacity with mechanisms to enhance mechanical and electrical integrity, the electric power system can achieve unprecedented levels of reliability, safety, and efficiency.

As wildfires continue to pose a significant threat to public safety, EEMS technology assumes a crucial role in risk mitigation by reducing grid vulnerability and the chances of wire-down situations, which can be a possible cause of wildfire. The enhanced mechanical strength provided by EEMS contributes to the overall resilience of the power infrastructure against many environmental hazards.

Higher Integrity Connection

In fact, after a few recent years of destructive wildfires devastating California, utilities in the state have installed over 50,000 of these types of shunts as a way to harden the grid for wildfire mitigation purposes. Since connectors are the weakest link in the system, it only makes sense to protect them. Correcting automatic splices or any overhead connectors with EEMS is faster, much less expensive than replacement and results in a connection of significantly higher integrity than even that of an original, properly installed connector. The installation can be performed without a power interruption, and the result is a thermally uprated connection and a visible indication that steps have been taken to protect the public against the possibility of yet another power line on the ground as a result of a failed connector.

EEMS provides a substantially higher integrity connection by several orders of magnitude than any other option, enabling a line to operate at increased ampacity without the limitation of connectors and allowing for system uprate and DLR implementation. DLR, on the other hand, directly addresses the challenges of transmission congestion and aging infrastructure. By dynamically assessing transmission line capacity based on real-time environmental conditions, DLR allows for the optimal utilization of existing infrastructure. This not only enhances transmission capacity but also minimizes the need for extensive and costly line upgrades. A recent report on California’s wildfire mitigation plan found that transmission line failures were responsible for 37% of wildfire ignitions in high fire-threat districts. These failures were often attributed to connector corrosion, fatigue, thermal cycling or improper installation.

Prioritizing the installation of EEMS and employing DLR technology enables utilities to significantly mitigate the risk of catastrophic failures, safeguard communities and safely increase electric grid capacity.

Reliability and Sustainability

In addition to addressing immediate challenges, DLR and EEMS technologies are essential to the broader context of energy transition and environmental sustainability. As utilities modernize electric infrastructure, prioritizing resilience and sustainability is paramount. By investing in technologies like EEMS and DLR, utilities not only enhance the reliability of their grid but also contribute to a more sustainable and resilient energy future.

In conclusion, the evaluation process for improving transmission lines should encompass a thorough condition assessment of overhead conductor connectors, considering their impact on system safety, efficiency, and capacity. This evaluation ensures the reliable operation of the electric grid while minimizing the risks of connector failures and subsequent disruptions. Many utilities have successfully used EEMS over the last 15 years to uprate splices and dead ends, significantly increasing ampacity and prolonging the life of conductors indefinitely. When combined with DLR technology in the uprating process, there is a high level of confidence in achieving positive outcomes. The integration of DLR and EEMS marks a paradigm shift, promising not just enhanced efficiency and safety but a resilient and future-ready electric power system.

Carl Tamm ([email protected]) is president of Classic Connectors USA Inc. and a 35-year veteran in the electric industry. He is a voting member of CIGRE’s U.S. National Committee, the IEEE Power & Energy’s TP&C committees, the ANSI C119 committees and former chair of the ANSI C119.7 committee. His extensive forensic analysis of hundreds of failed connectors has made him a leading authority and subject matter expert in connector failure causes on overhead power lines.

Seydou Diop ([email protected]) a principal engineer at Classic Connectors USA Inc., brings 15 years of experience in the electrical industry and holds key roles in IEEE OHL and ANSI C119 committees. As a former NEETRAC board member and chair of the ANSI C119.4 committee, he specializes in designing and qualifying overhead line hardware, with advanced expertise in failure analysis. Diop has served as an expert witness, in various legal proceedings related to wire-down incidents.

Chris Costanzo ([email protected]) is director of marketing and communication and one of the founding members of Classic Connectors USA Inc. He has over 40 years of experience as a sales and marketing professional, with 20 of those years in the electric utility industry and 5 years in the electrical contractor industrial market. He is a content developer, writer and editor in the electric utility industry, focusing on topics related to wire-down incident prevention.

How Does DLR Affect Connectors?

By J.D. Renowden, JDR Engineering Inc.

Why do increasing line loads accelerate the deterioration of line connections?

l Dynamic line rating (DLR) allows a line to be loaded above its normal static ampacity rating when current weather conditions cool it below its maximum conductor operating temperature (MCOT).

l The allowable increase in line load is calculated by DLR software to keep the conductor temperature at or below its MCOT, mainly to prevent ground clearance violations but also to limit annealing.

l Even though the conductor temperature is at or below its MCOT, the internal heating in the connection interface is greater due to the higher I2R heat there.

l The higher current and internal heating accelerates the deterioration of the interface and increases the resistance, all other deterioration factors such as installation errors and water ingress being equal.

Why should the resistance of a connector be the indicator of its absolute condition?

l Resistance is what increases as the connection deteriorates and is directly measurable.

How has this been determined?

l Direct measurement of resistance on energized in-service connectors, with a hot-line Ohmstik, correlates with heating shown by Infrared imaging.

About the Author

Carl Tamm

Carl Tamm ([email protected]) is president of Classic Connectors USA Inc. and a 35-year veteran in the electric industry. He is a voting member of CIGRE’s U.S. National Committee, the IEEE Power & Energy’s TP&C committees, the ANSI C119 committees and former chair of the ANSI C119.7 committee. His extensive forensic analysis of hundreds of failed connectors has made him a leading authority and subject matter expert in connector failure causes on overhead power lines.

Seydou Diop

Seydou Diop ([email protected]) a principal engineer at Classic Connectors USA Inc., brings 15 years of experience in the electrical industry and holds key roles in IEEE OHL and ANSI C119 committees. As a former NEETRAC board member and chair of the ANSI C119.4 committee, he specializes in designing and qualifying overhead line hardware, with advanced expertise in failure analysis. Additionally, Diop has served as an expert witness, offering expert opinions in various legal proceedings related to wire-down incidents.

Chris Costanzo

Chris Costanzo ([email protected]) is director of marketing and communication and one of the founding members of Classic Connectors USA Inc. He has over 40 years of experience as a sales and marketing professional, with 20 of those years in the electric utility industry and 5 years in the electrical contractor industrial market. He is a content developer, writer and editor in the electric utility industry, focusing on topics related to wire-down incident prevention.