Commonwealth Edison (ComEd), a unit of Exelon Corp., provides electrical service to most of northern Illinois, U.S., and is continually striving to improve the overall reliability of its distribution system to provide the highest possible level of service to customers. One effort over the course of the last seven years has been to deploy large numbers of traditional loop-scheme (LS) reclosers on its 12-kV distribution feeders.

As these efforts to improve reliability have progressed over the years, ComEd has recognized the need to use reclosers with advanced technology to further leverage the return on investment of its existing distribution automation (DA) equipment. It has been determined this advanced technology can be deployed effectively within traditional LS recloser schemes to further minimize the number of customers affected when a fault occurs on the distribution system with minimal modification to the existing devices.

Extending Automation

ComEd is in the midst of a major project to improve reliability — by increasing the segmentation of its distribution feeders to reduce the number of customers affected by any given outage — through further use of advanced DA equipment. Wide-scale use of conventional loop schemes has proven successful in improving the utility’s system average interruption frequency index (SAIFI) and customer average interruption duration index (CAIDI) metrics; however, the segmentation limit of these schemes has been reached.

ComEd has prioritized applying DA on feeders with the most customers and those with the worst reliability issues. As the project has progressed, the utility has found that the criteria for what is an acceptable number of customers in a given feeder segment has changed, with a need to further reduce the number of customers in any given feeder segment. To meet the reliability metrics that ComEd has committed to achieving, the utility needs to install additional DA on feeders where a base level of DA is already applied.

At this point, ComEd is deploying advanced-technology DA devices with pulse-closing capability within existing recloser loop schemes to allow the existing assets to continue providing significant return on investment. Ultimately, the utility’s goal is to meet the objectives of Illinois’ smart grid legislation, the Energy Infrastructure Modernization Act, economically.

A conventional loop scheme deployed on a large-customer-count feeder at ComEd typically consists of a normally closed recloser at the midpoint of both feeders with a normally open tie recloser between the two feeders. Should a fault occur on either feeder, only half of the total customers fed by the affected circuit would experience an outage as the LS reclosers reconfigure automatically to isolate the faulted section of line and restore the section that is not faulted.

The benefit of LS is to reduce the SAIFI by one-half since only half of the customers would be affected by the outage. Also, CAIDI is improved since fault current magnitude and phase information is available from the devices through supervisory control and data acquisition (SCADA) to determine the approximate fault location.

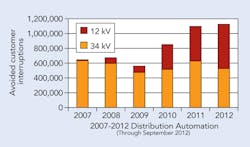

The deployment of LS over the years has clearly provided improved reliability. The number of avoided customer interruptions (ACI) at ComEd has increased as DA has been added. From 1999 through 2002, ComEd installed distributed intelligence-based DA with peer-to-peer communications on its 34.5-kV circuits. As a result, up until 2007, ComEd’s ACI were predominantly a direct result of the correct operation of the 34-kV DA equipment.

Beginning in 2007, ComEd began another major effort to install DA on 12-kV circuits. As 12-kV DA was added each year since 2007, the annual 12-kV ACI has increased significantly. In 2011 and 2012, more than 1 million customers did not experience an outage because of the proper operation of DA equipment. In 2012, more than half of ComEd’s ACI were a direct result of its 12-kV DA.

Beyond Loop Schemes

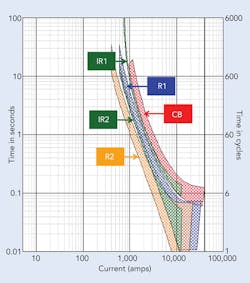

Despite this success, ComEd has found loop schemes have significant limitations when it comes to being able to break large-customer-count feeders into smaller sections. ComEd has found that maintaining proper time-overcurrent coordination between traditional reclosers in a loop scheme containing more than three reclosers is extremely difficult to consistently achieve. Also, the utility has found that repeatedly closing into faults can cause damage to distribution equipment (I2t damage).

Additionally, in some instances, customers fed by different feeders served from the common substation bus have complained about voltage depression when LS reclosers have closed into faults while working in a fault-hunting fashion to isolate the faulted section of circuit. When a recloser is added to an existing loop scheme in an attempt to further segment the feeder into smaller segments, the new recloser must coordinate with the existing recloser and substation circuit breaker, as well as downstream fuses. This is difficult to achieve because of the small available space between the existing LS time-current curves in which to fit another traditional recloser time-current curve while maintaining proper coordination.

Over the last two years, ComEd has deployed S&C’s IntelliRupter PulseClosers in several loop-scheme configurations to test its compatibility with the ComEd distribution system. One of the features of the IntelliRupter is the device’s tighter tolerances for coordination as compared with traditional reclosers. Basically, the accuracy of the integrated mechanism, control and sensing provide tighter coordination tolerances. The tighter coordination tolerances allow more curves to be stacked together, which should allow more devices to be installed in series and still coordinate properly.

ComEd approached S&C about trying to use these tight tolerances to help overcome the coordination issues limiting further segmentation of existing loop schemes. Time-overcurrent coordination studies proved this should be possible in most instances. The much skinnier curves provided by the IntelliRupter can be shoehorned between existing recloser curves to fit into the existing ComEd loop schemes.

Another advantage of this advanced technology that became apparent as ComEd and S&C worked together is how the pulse-closing feature might be brought into play as a backup should perfect coordination not be achieved at certain fault magnitudes.

A pulse close is a lower-energy test of the line. Basically, if the condition arose where both the IntelliRupter and the traditional recloser would trip because of a fault, the recloser would still be able to reclose and hold because the pulse-finding feature of the IntelliRupter would force it open when the upstream recloser opened. After the recloser reclosed and held, the IntelliRupter would use pulse closing to test for a fault instead of testing for a fault like a traditional recloser.

Pulse closing is a fast close-open operation at a precise point on the sine wave. This produces a pulse of current though the line, which the IntelliRupter can then analyze to determine whether the line is still faulted. This small pulse of current is not enough to cause the upstream recloser to trip, thus proper segmentation is achieved even in instances where initial coordination cannot be achieved.

Both Directions

Another advanced feature of the IntelliRupter critical to the success of the project was its ability to support bidirectional profiles at the same time. Basically, the device needed to have the ability to look in the forward direction down the line with time-coordination curves that are entirely different than what it would use when looking in the backward direction. This is required so coordination is maintained even when the scheme is reconfiguring during an event. ComEd especially appreciated that the device has this capability without requiring any sort of control reboot to change profiles.

In addition, ComEd is seeking to quantify whether the pulse closing can assist with reducing equipment damage to its distribution system resulting from additional fault current flowing when the traditional DA devices reclose to test for faults. Since the pulse-closing interval is for such a short time, very little energy is passed through the distribution system while testing to find the fault section. A pulse close contains less than 2% of the energy typically let through during a traditional reclosing. As a result, ComEd hopes to see a reduction in related equipment damage and customer complaint issues.

A New Approach

ComEd and S&C worked together to build a typical ComEd LS circuit in S&C’s high-power test lab. They used actual ComEd LS settings in the types of devices ComEd has deployed over the years. IntelliRupters were inserted into the scheme in the manner expected to be deployed in the field. They then tested each fault and loss-of-voltage scenario at typical ComEd primary voltage levels and fault magnitude levels. As predicted, they were able to maintain coordination for each scenario. Additionally, the scheme reconfigured properly in each instance.

One of the issues ComEd had to overcome to successfully deploy the scheme was getting a traditional normally closed LS recloser to close back in toward the source after it initially opened as a result of loss of voltage. ComEd’s traditional normally closed LS reclosers do not have built-in logic available that would allow them to reclose after voltage is restored as the scheme works to automatically restore load. To enable this functionality would have required creating custom logic.

Because of concerns with developing, fully testing and maintaining custom logic, ComEd wanted to avoid creating customized complex logic within its existing recloser controls. The solution to the problem was to bring in another source to the scheme just upstream of the normally closed traditional recloser. This would typically be required anyway since large feeders rarely have the available capacity at peak load to fully restore another large feeder.

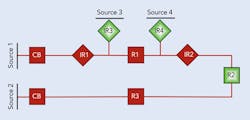

As a result of research and successful lab testing, ComEd is proceeding with field deployment of this advanced technology within existing loop schemes. The two feeders currently have an existing LS comprised of R1 midpoint, R2 loop tie and R3 midpoint. The feeder fed by Source 2 will need to be segmented further to improve its reliability. Two additional normally closed IntelliRupters will be installed in the existing LS (IR1 and IR2). Two new normally open IntelliRupters also will be installed (IR3 and IR4). IR4 is required because of the capacity constraints of Source 2. This will result in breaking the Source 1 feeder into four sections, further improving its overall reliability without creating miscoordination issues and without requiring additional recloses associated with traditional reclosers and sectionalizers.

The Goal in Sight

ComEd will be able to achieve its goal of improving the performance of its distribution system through economical and effective use of advanced reclosing technology. Along the way, ComEd further expects to avoid wholesale replacement of existing LS reclosers, thus allowing these existing DA assets to continue providing an even greater return on investment. Finally, the utility expects to move toward using the advanced technology to minimize damage to other distribution system components.

Based on these benefits and along with documented history of excellent results to date, ComEd fully expects to continue using DA as one of its most cost-effective tools for achieving excellent distribution system reliability.

Acknowledgement

The author expresses sincerest appreciation to Angie Schuler, assistant manager of automation and communication services, and Dave Kearns, application director of smart grid technologies automated systems division, both at S&C Electric Co., for their significant contributions in preparing this article.

Jeff Gates ([email protected]) is a senior engineer in Commonwealth Edison’s distribution automation department, which monitors the performance of the ComEd distribution automation system, establishes settings and coordinates the installation of new distribution automation equipment. He has been with ComEd for 22 years, working in the utility’s construction and maintenance department and distribution testing department prior to joining the distribution automation department. He holds a BSEE degree from the University of Illinois Urbana-Champaign.

Companies mentioned:

Commonwealth Edison| www.comed.com

Exelon| www.exeloncorp.com

S&C Electric| www.sandc.com