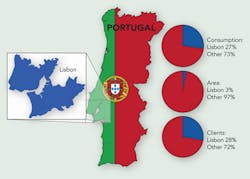

The Lisbon operations (DRCL) area is part of the Portuguese distribution utility EDP Distribuição, comprising an area of 2,896 sq km (1,118 sq miles) with a population of some 2.7 million inhabitants. Although the Lisbon operational area only represents 3% of the Portuguese mainland, it supplies 28% of the customers who consume 27% of the total electric energy consumption.

EDP Distribuição has launched Project OMDRCL in Lisbon with the main objective to ensure customers receive a high reliability of supply and improved customer service in terms of energy metering. This requires the need to optimize the capabilities of the existing network with its new developments and improved management processes, which also include sustainability and environmental control programs. This project satisfies the growth in energy demand and the drive for improvement by addressing network equipment, workforce management, information systems, automated metering and microgeneration.

Workforce Management

To improve operational efficiency, EDP Distribuição is implementing workforce management (WFM) to replace the less efficient processes in commercial services, network operations and the follow-up on network incidents. The utility now uses Internet-based systems to assign work to field teams on site. This new methodology is gradually replacing voice communications and former paper-supported processes, and offers the advantage of retaining digital records of all communication exchanges.

Work programs are managed from the office, so the office-based team retains the authority and ability to issue individual work assignments for special or urgent tasks. The system also allows a work package assignment to be issued for immediate action or for the following day.

All field teams have a personal digital assistant (PDA) with a specially developed application that receives work tasks from the office. These tasks contain detailed information of the work needed as well as additional data held in the corporative systems that might be useful for any complementary job.

As tasks are performed, the team achievement is updated via the PDA device, according to predefined stages. The updated information is received and saved in the office, so all the information and updates are immediately recorded on all corporative systems. This reduces the possibility of errors that can occur within manual updating systems, and it allows call center operators to provide customers with detailed and accurate information on the progress of any specific field operation.

The New Way

The WFM-developed software, together with the PDA being a user-friendly interface, has helped to reduce major errors in corporative systems updating. Prior to the WFM, these tasks were done by the field teams, and corporative systems were updated manually. The WFM has increased efficiency, as it is now easier and faster to manage teams and to keep the corporate systems automatically updated. It also allows quality improvements and a centralized control system from which efficiency is measured. This previously almost impossible task is now possible because all the information is saved in the system, and every stage of a process can be thoroughly analyzed.

The WFM-PDA also includes a GPS navigation tool to plan itineraries. To increase efficiency, the navigation tool includes a record of all the medium-/low-voltage (MV/LV) transformer cabinet locations. It includes a fast-response facility for urgent tasks so teams can be managed in a more flexible way, without the need to consider whether they are familiar with a particular geographical area.

The rapid response provided with WFM is also partially responsible for the improvement of MV network reliability measured by the main fault outage performance indicator: TIEPI (Equivalent Interruption Time for Power Installed [minutes of lost load]). The quality measured by TIEPI is defined by the effects of outages verified in a geographic area in a certain period of time. This requires consideration of the number of outages, their duration and the load lost due to the outage related to the total installed capacity for the geographic area. The decrease in TIEPI from 2008 through 2013 was 52%.

Corporative systems support all the work developed and undertaken within EDP Distribuição; therefore, systems integration is a valuable tool to improve the overall efficiency. Together with WFM, there are some other systems that are extremely important in the operations rollout.

New Tools

Power-On is an integrated system for operational management at all voltage levels. This tool uses the geographic information system (GIS) for network status. By changing one network element in Power-On, because of a line outage, for example, the system automatically indicates the affected network, the customers affected by the network outage and the priority actions to be taken to restore supplies to the affected customers as fast as possible. There was also a need to transform the network data held in a schematic form from the prior program in use to the new geographically based system.

Power-On also communicates with supervisory control and data acquisition (SCADA)/Genesys, making network management faster and easier. So the combination of Power-On together with WFM and the increasing number of remote-controlled MV/LV transformer cabinets has resulted in major improvements in TIEPI.

New projects for network expansion are developed with a design tool — as a starting point, Design Manager — that allows the use of the existing network on GIS. The project design tool is used to guarantee a fast and efficient network upgrade. However, Design Manager is more than just a design tool, as it helps in project management from the planning stage to the direct integration of the network expansion.

Third-Party Systems Integration

Many of the developed system tools are designed to be compatible with the needs of the external service providers (ESP). Examples of this success option are the WFM office compared with the prior systems for fault and incidents follow up, as well as the commercial field operations control. The commercial field operations control systems are developed to fit the needs of EDP Distribuição and the ESP as it is an activity that already controls 95% of the external field executions.

All DRCL customers are visited at least once every three years, often at their own request, for tasks such as evaluating the adequacy of the metering system for new contract options. This excludes meter reading visits, which are conducted every three months.

To optimize commercial field operation processes, a simple contract was designed with only a few payment rules that include a large set of field activities that might be developed in association with metering equipment. Using this system, EDP Distribuição can associate the payment for each work order executed by the ESP. This process has major advantages for EDP Distribuição, which only needs to control the quality of the work executed and the type of payments for the work done in the field. The ESP has the advantage of fast payments for completed work.

Remote Metering

Focusing on the network optimization and management to minimize the effect of outages, a large number of MV/LV transformer cabinets are being equipped with remote-control systems based on the importance of the customers supplied, the network load and the difficulty to access the installations. The installation of remote-control metering equipment is also contributing to the operations optimization project. In DRCL, all MV clients are already equipped with remote energy metering. The most common method is to attach a GSM modem to the energy meter. This solution is being installed gradually for special LV customers whose load exceeds 41.4 kVA and for microgeneration applications. Other solutions are being tested in DRCL network using either GSM or powerline communication systems.

Network Equipment

To optimize network assets, EDP Distribuição introduced a policy whereby existing distribution transformers are relocated to ensure that transformers with excess capacity are moved to substations experiencing a higher demand. This simple procedure allows for network improvements without the need for further capital expenditure.

In seeking to operate the network with optimal utilization of MV/LV transformer capacity, achieved by loading the units close to the nominal nameplate rating, the electromagnetic losses are minimized. This reduces the need for additional MV/LV substations, which is especially important in high-density neighborhoods where land is a premium and substation sites are difficult to locate. One of the utility’s more ambitious undertakings, linked to environmental concerns, is the program and the procedures used to verify and replace, wherever required, those distribution transformers with insulating oil containing PCB.

Microgeneration

In consideration of the aim to reduce CO2 emissions linked to energy production, and in accordance with European Union regulation and the normative levels established in Kyoto Protocol, the Portuguese government has introduced customer-based incentives. The new methodology will give LV customers incentives to install energy production equipment to produce energy for their own consumption. The renewable energy sources to be used include solar, wind or cogeneration.

The process for a regular customer to become an energy producer is easy. It requires registration in a specially designed Internet portal, and the selection of the generation solutions presented and the equipment installers, without the need for the usual exhaustive project design and approval processes.

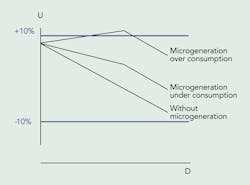

The selected solution is often connected to the existing LV supply installation, so the energy delivered to the network is measured via a meter with a GSM modem. This provides the distributor with information when required. However, the energy infeed to the distribution network is limited to 50% of the customers’ contracted demand for energy.

The existing regulations define special monetary conditions for those customers who simultaneously install equipment for water and heating systems, if the maximum installed load is less than 3.68 kW. The maximum allowable load that can be installed is limited to 5.75 kW, although values above 3.68 kW are no longer entitled to government monetary support. All the energy supplied to the existing LV distribution network receives a payment based on each kilowatt produced above the regulated threshold.

Therefore, regulation now allows customers who suffer LV problems to install a microgeneration system to rectify the problem. However, there is one limitation for self-produced energy inflow into the network: The summation of all the power generated by microproducers cannot exceed 25% of the installed capacity of the MV/LV transformer cabinet supplying the area; otherwise, it would cause power flow problems on the network.

Network Development

The representation and characterization of the electric networks, jointly with the cartographic base in a digital format used for referential installations, constitutes a strategic resource for network knowledge.

The technological developments are key tools to reinforce network operations, opening the door for the standard network development into smart grids through processes already taking place in EDP Distribuição – Inovgrid.

All the network development initiatives improve management operations, which, when coupled with the increasing knowledge of customer energy demands and expectations, will help EDP Distribuição to deliver the level of service required to achieve the goal of being a network operator reference utility.

Paulo Lúcio ([email protected]) was awarded an electrical engineering degree from Instituto Superior de Engenharia de Lisboa (Lisbon) in 1996 and joined EDP Distribuição. Lúcio began working on maintenance before moving to LV network connections. In 2007, he moved into the Commercial Assistance Lisbon’s department, responsible for energy metering equipment activities and smart grid implementation. He joined Network Planning Lisbon’s department in 2010, responsible for the planning and design of MV/LV network projects in Lisbon municipalities. Lúcio now works in Commercial Operations on activities related to energy metering equipment operations and remote metering analysis. Lúcio has coauthored technical papers presented at recent CIRED conferences.

Pedro Paulo ([email protected]) was awarded an electrical engineering degree from Instituto Superior Técnico (Lisbon) in 2001 and joined EDP Distribuição, working initially on MV/LV network design and project management. In 2004, Paulo moved into the maintenance department for Lisbon’s network area, working on CBM techniques for MV/LV cables. Currently, Paulo works in the Commercial Assistance Lisbon’s department on activities related to energy metering equipment and smart grid implementation. Paulo has coauthored technical papers presented at recent CIRED conferences.

Miriam Boucinha ([email protected]) was awarded an electrical engineering degree from Instituto Superior Técnico in 2004 and joined EDP Distribuição. Boucinha started her career on the maintenance activities, before moving to the metering department, dealing with information validation and delivery for the Iberia energy market. Boucinha has coauthored technical papers presented at the CIRED conferences since 2007.

Company mentioned:

EDP Distribuição | www.edpdistribuicao.pt