As Superstorm Sandy approached the East Coast in October 2012, grid operators at PJM Interconnection braced for the severe tests of people and equipment that often come with extreme weather. But, thanks to the recently commissioned Advanced Control Center (AC2), the PJM operators had a powerful new tool for maintaining uninterrupted control over vital grid functions.

PJM, a regional transmission organization (RTO), now has more than a year of experience with the state-of-the-art technology systems developed as part of the AC2 program. Those systems run the power grid and administer wholesale electricity markets in 13 states and the District of Columbia in the eastern and central United States, comprising a large part of the Eastern Interconnection.

During the past year in which AC2 has demonstrated a record of 100% availability for reliability tools, the RTO has managed the grid successfully through several challenges, especially those weather-related, including a summer of searing temperatures, the derecho windstorm of the summer of 2012 — with straight-line winds 200 miles (322 km) wide and 600 miles (966 km) long — and Hurricane Sandy and its aftermath. The new AC2 technology systems enabled PJM grid operators to respond even more effectively than it had in the past.

Dual Control Centers

Commissioned on Nov. 8, 2011, AC2 features two fully functional control centers and data centers located at distant sites. Both sites are staffed 24/7 and simultaneously share responsibilities for operating the transmission system and PJM-administered wholesale electricity markets. Either site can run the RTO’s entire system independently should the other become inoperable.

As part of the more than five-year (800-person-year) development process, PJM closely examined the data-gathering efforts and decision-making techniques needed to preserve grid reliability. Measuring the time it takes operators to read alarms, process information and assess the work flow, the RTO developed visual displays that increase situational awareness, thereby improving the accuracy and certainty of the dispatchers’ actions.

By coupling intelligent alarm processing systems in the control rooms with advanced technologies, system operators can rapidly interpret patterns and spot potential grid weaknesses more quickly and with greater assurance. These technologies not only respond to ever-changing system conditions but also learn from operational events under selected conditions to help the operators keep electricity supply and demand in balance so the lights stay on.

PJM is the only grid operator in North America — and one of two around the world — to have two primary control centers. This configuration of dual primary capability reduces the risk to the region PJM serves, its people and the economy by helping to ensure uninterrupted operation of the electric system and markets.

As part of the program, each of the RTO’s control rooms was designed and updated to provide the same technology, work flows and human-factor engineering tools, permitting flexibility in staffing assignments between centers. New computer systems and applications were developed and installed as part of AC2. In addition, new and expansive video walls were developed and installed to make more operational data available for review in real time. A new video wall was built specifically for reliability engineers, and video teleconferencing is available for all consoles between the dual sites.

The Technology Approach

In terms of information technology, AC2 was envisioned to move PJM’s systems and capabilities to new levels of security and resiliency instead of opting simply for marginal improvements to the legacy technology systems. It has accomplished that. The cutting-edge approach adopted in AC2 enables the RTO to incorporate new technology developments quickly, scale to accommodate growth, enhance reliability and protect against sophisticated security threats.

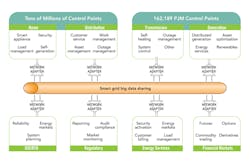

The AC2 program was a breakthrough in creating a shared architecture for a new generation of energy management systems (EMS) and market management systems. Significantly, it marks the first industry implementation that employs a shared architecture platform and places standard interface definitions supporting system integration into the public domain, allowing grid operators and member electric utilities to integrate software systems that support reliability.

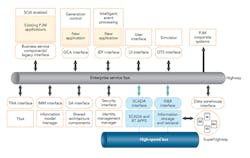

The service-oriented architecture (SOA) enables business systems and their applications to share information easily and securely. Different applications and devices can be plugged into the control system and communicate with each other through standardized communication protocols and procedures. This industry-transforming approach invites continued refinement and innovation in grid monitoring and control systems while maintaining security. It also invites innovation from technology providers beyond those vendors that traditionally supply the electric industry.

With AC2 fully integrated into its operations, PJM now has the most modern, state-of-the-art system in existence today for managing the grid and electricity markets.

The Genesis of AC2

As early as 2001, PJM began examining the need to strengthen its business resiliency. The review reflected not only its increasing geographic scope and market size but also recognized the security implications of the growing potential for cyber or physical disruptions aimed at the grid.

Fundamental to these discussions, too, was the understanding that the RTO’s technology architecture and legacy systems soon would reach the limit of their ability to scale up and remain secure. While the staff had accomplished several integrations of new members and territories successfully, it was clear the point-to-point method of data transport and interaction (for example, custom bridges to share data) among applications was becoming a limiting factor and a source of risk in terms of maintenance, productivity, flexibility and security.

Old Point-to-Point Model

Based on these issues, PJM conducted extensive requirements and design analyses, and then created a technology strategy laying out a plan to address the shortcomings of the legacy architectures. This strategy endorsed the adoption of SOA as the framework for the new system, as the RTO found it would improve reliability and security while managing long-term operational and maintenance costs.

As part of the SOA architecture, an enterprise service bus was selected to handle all the interaction and communications among the various software applications, or services, to minimize unnecessary development risk. The enterprise service bus acts as the gatekeeper for the system, enabling and monitoring the interfaces between the applications without them having to contact each other directly, as in the point-to-point model.

For example, data from the numerous applications that are part of PJM’s tools for members are not sent directly to the various applications in the EMS or to the settlements (billing) system, as would be the case in the old point-to-point model. With the enterprise service bus, applications subscribe or publish the data in the form of a message, and the message is sent to the bus, which then delivers the message to the applications that need it.

In effect, the various applications (EMS, market management system and settlements system) plug in to the enterprise service bus and receive and transmit information through it. This design also promotes efficiency in subsequent development and testing. For example, a new application intended to replace a legacy application can be plugged in alongside the application in a test environment and monitored for quality, accuracy and availability prior to promotion to the production systems. This capability improves overall productivity and eliminates risks to production systems and downstream business processes.

The SOA also provides a natural migration path for technology investment. Recognizing it is not always feasible — because of financial constraints and business risks — to replace every business application, the shared architecture framework makes it possible to prioritize the redesign and replacement of any part of the existing technologies.

In this case, PJM chose to develop with Siemens Energy & Automation an entirely new management system application and specialized application features to replace the legacy system. A partnership agreement to develop the new control center architecture of AC2 was signed in 2006. At the same time, the RTO partnered with Alstom to upgrade the major components of the market management system to improve interoperability and provide for more efficient dispatch.

In addition, the architecture improves the management of the enormous amounts of data that must be collected and maintained in managing the grid and markets, including the data from smart grid applications that will be integrated into the new technology.

Outside of the Box

With the strategy in place — and with the recognition the SOA and enterprise service bus architecture had never been employed in real-time electric system and market operations — PJM began an effort to identify industry and technology firms to collaborate in creating the technological foundations for the AC2 program.

Concurrently, the RTO cosponsored a working group through the Very Large Power Grid Operators organization, now called the GO 15, a global industry body made up of the world’s largest electric grid operators, to identify the framework and principles that could guide the development of the next generation of EMS.

In this endeavor, PJM’s objective was to identify a global

design for an EMS that would break the expensive and limiting cycle of custom, one-off technology projects that frequently prevented neighboring systems and grid operators from easily exchanging operational information that could enhance reliability.

Two major events — the attacks on Sept. 11, 2001, and the Northeast blackout on Aug. 14, 2003 — gave additional impetus to the focus on security, resiliency and reliability as the AC2 design and development work proceeded.

Innovation Pursued

PJM sought a collaborative approach with potential vendors and argued that the key results of the collaborative effort should provide a system that supports interoperability using a component-based architecture.

The RTO believed such an approach would provide an incentive for continued collaboration by vendors and buyers of future systems. Placing the standard interface definitions into the public domain would encourage innovation and new, small or non-traditional software developers to adapt and evolve the designs.

The collaborative approach also offered the opportunity to jointly simplify requirements, specification, bidding and procurement processes, as well as to develop proven de facto standards for the evolving independent system operator/RTO industry sector.

A key element of AC2 is the new Siemens Spectrum Power Energy Management System, which is designed as a service-oriented system to interoperate with the new shared architecture technology platform. The success of the SOA and enterprise service bus employed in the AC2 environment demonstrates that innovative information technology can be adapted to the high-performance, mission-critical environment of the electricity industry and smart grid implementation.

The shared architecture approach provides a standardized integration platform for applications that differ in technology, design or vendor, yet interoperate seamlessly together like energy management, market management and even distribution management systems. This SOA also enables traditional utility applications to be integrated with smart grid applications, providing the options and a level of flexibility not possible with older grid management and control center software systems.

Scalability has always been important to PJM and its members. The greatly enhanced data management capabilities brought about by AC2 enable the system to readily accept smart grid applications. For example, the architecture can integrate the massive data streams from the increasing number of phasor measurement units (with approximately 30 data samples/second) being installed across the PJM region and provides a platform for innovation as phasor measurement unit analytics and business intelligence applications evolve.

Business Benefits

AC2 enables PJM to realize significant benefits:

- Increases the RTO’s operational efficiency

- Builds security into the underlying architecture

- Enhances business flexibility

- Accelerates the creation of new business processes and applications

- Provides plug-and-play capability for new power system services

- Establishes an industry-standard messaging architecture and two-way communications for the RTO’s members and others.

The business benefits of adopting a SOA also include improved design and development times for new services, such as significantly reduced testing times. These positive attributes reflect the fact applications can be assembled from reusable components, rather than having to be written with custom point-to-point communication and application designs. Once the message formats, data payloads and applications producing or consuming the messages are identified, developed and tested, they serve as the foundation for all future designs and extensions.

Critical to adopting a SOA approach is a careful mapping of every business process and data transfer so they can be incorporated into the architecture. Each application must be considered in terms of whether it will be entirely rewritten, retested and moved to the production environment. In PJM’s case, only critical function applications were rewritten. To reduce business risk, other applications received adapters to permit the transport of the legacy applications’ data across the new architecture.

With the successful conclusion of the AC2 development program, PJM and Siemens continue to seek partners in innovation to further develop the shared architecture approach and play a role in the creation of integration standards for smart grid architectures for the industry.

By integrating security, scalability and flexibility into a new generation of technology systems, the shared architecture of AC2 provides a flexible platform for growth, innovation and new technologies to advance the industry’s mission.

Forward-Thinking Innovation

Beyond its direct benefits, AC2 symbolizes PJM’s commitment to being on the cutting edge of innovation. The innovation embodied in AC2 means the RTO will never again have to perform a forklift replacement of the EMS, markets and control systems. Instead, it will plug and play each new improvement or innovation as it is developed.

Terry Boston ([email protected]) has served as president and CEO of PJM Interconnection since 2008. He oversees the largest power grid in North America and the largest electricity market in the world. Boston also is president of GO 15, the association of the world’s largest power grid operators. He serves on not-for-profit boards, such as EPRI, the Association of Edison Illuminating Companies and Grid Protection Alliance.

Companies mentioned:

Alstom| www.alstom.com

PJM Interconnection| www.pjm.com

Siemens Smart Grid| w3.usa.siemens.com/smartgrid/