Gaining Maximum Return on HVDC Systems with Targeted Refurbishments

The demand for electricity is growing and that is set to increase over the coming years. The economies among the emerging nations continue to expand access to electricity while the desire to decarbonize the global energy system will lead to an increase in the demand for electricity in the developed world.

According to the International Energy Agency's (IEA) World Energy Outlook 2018, global electricity demand in 2018 increased by 4% or 900 TWh, growing nearly twice as fast as the overall demand for energy. This was the fastest increase since 2010 when the global economy recovered from a financial crisis.

This growing power demand and a worldwide push for the decarbonization of energy systems call for a new approach in power transmission with less central generation from the traditional fossil fuel plants and greater reliance on renewables and distributed generation. The challenge is to develop effective and reliable bulk power transmission systems on the one hand to get power from bigger renewable energy parks to the load centers and on the other hand to strengthen the weakened and less stable grids which can include refurbishment. One answer that is becoming increasingly popular is high voltage direct current (HVDC) transmission systems, particularly for connecting two independent grids for stabilization purposes.

Even though HVDC systems have been around for more than 30 years, they are now becoming more useful than ever. Apart from the installation of new HVDC systems, existing HVDCs also have the potential to further support the changing grids. As the grids are changing, HVDC technology is also evolving. This provides opportunities such as the implementation of new features to meet new market dynamics as the generation system evolves over time.

These new features can be installed as needed and should be considered during necessary refurbishments which are triggered by a variety of reasons. From exchanging of core equipment to extending the system’s lifetime to midlife refurbishments triggered by aging IT infrastructure, being a complex system with various components based on power electronics with a smart IT infrastructure, the lifetime of the equipment obviously needs to be taken into account for smooth operation of the HVDC system.

Extending the Life of HVDC Assets

One example of this came from India's oldest HVDC link, in the central Indian state of Madhya Pradesh. The Vindhyachal 500-MW HVDC back-to-back system was commissioned in 1989 to interconnect the asynchronous 400-kV alternating current (ac) networks of the northern and western regions.

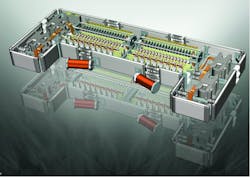

The project's scope includes the installation of modern light-triggered thyristors that are exclusive to Siemens. These have a higher voltage blocking capability to replace the old electrically-triggered thyristors. This will reduce the number of thyristors by 50%, reducing power loss. Thyristor valves are at the heart of HVDC conversion either to or from ac. In modern HVDC classic systems, thyristor valves are arranged in stacks and suspended from the ceiling in a valve hall instead of the floor-mounted valves that were used in former HVDC classic systems. Also, part of the refurbishment is the converter cooling system, HVDC control and protection system, direct current (dc) measuring devices, and surge arrestors.

Overcoming Network Disruption

Midlife Refurbishment

Not only do the features to be implemented need to be planned carefully to conduct a refurbishment as smooth as possible, but also the work and required outage have to be scheduled well in advance. As HVDC transmission systems are assets that can have a significant impact on daily life by disrupting the energy supply, the timing of any refurbishment is vital. Throughout any upgrade, planning is crucial to ensure reliability and maintain availability. The upgrade of the Trans Bay was delayed because San Francisco was hosting Super Bowl 50 between Denver Broncos and Carolina Panthers — an event that attracted tens of thousands of extra visitors to the Bay area.

The control and protection (C&P) systems, much like other IT infrastructure have a shorter lifespan than the hardware and will often require a midlife refurbishment after 15 to 20 years. As with all modern IT infrastructure, the lifecycle of C&P systems is shorter than that of HVDC systems. Because of obsolescence of spare parts and for cybersecurity reasons, the aging systems need to be refurbished.

That was the case with the refurbishment of the 600-MW Welsh HVDC station in Titus County, Texas, the United States. The 20-year old facility had its C&P system upgraded to meet the challenges of the continuously evolving grid. The Siemens SIMATIC TDC controls that were installed are a fully digital offering, resulting in faster and more accurate operation. The controls will improve the reliability and availability of the station which enables power exchange between independent networks.

As part of the midlife refurbishment, the cooling, heating, and ventilation systems were replaced, and new harmonic filters and shunt reactors were fitted. Since the facility was commissioned back in 1994, there has been a significant shift in the pattern of network operation that has led to increased levels of harmonics in the systems. An increase in harmonics is a disruption to the regular operation of a network that can lead to interruptions in power supply. Armed with advanced harmonic filters, system operators can control the increased level of harmonics and deliver more reliable power.

Implementation of Latest Standards

Occasionally, a refurbishment can have a dual purpose. Such was the case with New Zealand's interisland connector. The project involved upgrading pole 2 with a new C&P system. At the same time, an additional pole was installed to replace pole 1 and increase capacity from 900 MW up to 1200 MW.

The newly installed equipment fulfills latest seismic requirements, which means the equipment is designed to withstand an earthquake of such strength occurring only once in 500 years. The massive valve hall for the substation is built on base-isolators, and the building can move up to +\- 750 mm during an earthquake. The valve equipment is suspended from the ceiling, allowing it to sway without being damaged.

One major challenge for Siemens on this project was that all the work was carried out on an operating power system. The new pole 3 had been installed while pole 2 had been in operation. After commissioning and testing of pole 3, the C&P of pole 2 could be refurbished. As a result, a new pole 3 was successfully connected to the refurbished pole 2, providing a power transfer capability of 700 MW and an overload capacity of 1000 MW for 30 minutes. Both systems are equipped with state-of-the-art C&P technology.

Extra Functionality for the Modern Grid

One significant advantage gained from adding latest digital technology during a software upgrade is increased visibility of the system that takes advantage of advanced components which incorporate more sensors allowing data to be accessed. This allows quicker identification of faults and the possibility to move over to a condition-based or predictive maintenance regime with all the associated improvements in reliability that are important to dispatchers.

There are also benefits when it comes to cybersecurity. The state-of-the-art protection that comes as part of a C&P upgrade is vital to meet current regulations such as NERC in the United States and ISO 27000 in Europe. While transmission is still the core business for operators, the added functionality that is available when upgrading to a modern HVDC system allows the company to look at supporting the grid by supplying ancillary services, as well as reacting to any changing energy market conditions.

About the Author

Sanjay Mukoo

Sanjay Mukoo is Lead Engineer for HVDC systems at Siemens in Erlangen. He is a member of IEC TC 115 WG 12 “Life Extension of HVDC converter stations”

Laura Stolle

Laura Stolle is Technical Sales for HVDC systems at Siemens with focus on HVDC refurbishments.