Fault Anticipation Improves Operations

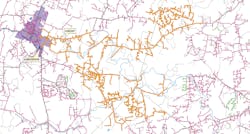

Distribution utilities operate miles and miles of lines to serve large service territories. Knowing what is happening on those lines presents a real challenge. Pedernales Electric Cooperative and other utilities are improving the reliability and safety of their electric power distribution systems, using technology developed by Texas A&M University’s College of Engineering. Known as distribution fault anticipation (DFA), the technology helps utilities to manage their systems better by giving them more awareness of what is happening on them.

Pedernales first began testing DFA in 2015, as part of a demonstration project known as the Texas Power Line-Caused Wildfire Mitigation project, supported by the Texas state legislature. As one of seven Texas utilities to participate in the project, Pedernales installed DFA monitoring on 11 distribution circuits. Pedernales and the other participants have used DFA to detect multiple line issues that otherwise could have started fires. Enhanced situational awareness increases crew efficiency and enables corrective actions that inherently improve service quality as well as reliability. Based on successful trials, Pedernales and several other utility companies have begun expanding their deployments of DFA, integrating DFA into their work flows and making DFA information available in their control centers.

Awareness Is Key

Knowing about a problem is the first step to correcting it. Pedernales uses 22,000 miles (35,400 km) of primarily overhead distribution lines to serve 300,000 meters across a service territory of 8100 sq miles (20,100 sq km). Unlike transmission lines — which generally run point to point or, perhaps, have a tee or two — distribution circuits have complex topologies with many branches and countless components. Distribution utilities cannot know the current condition of every component. A utility often learns of outages and other problems from customer reports.

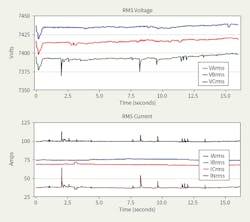

Supervisory control and data acquisition (SCADA) and other conventional technologies provide notification of gross events, such as when a high current fault trips a substation circuit breaker. Smart meters can provide additional information, such as blink counts and targeted pings. DFA research and field demonstration programs have shown incipient failures of line components sometimes cause low-amplitude electrical changes, measurable from substation sensors; however, SCADA and smart meters are not designed to detect these changes and, thus, cannot alert the utility to such problems.

Electric service is fundamental to modern society, but despite prudent construction standards and operational procedures, electrical events can cause fires. DFA technology provides awareness of some line conditions capable of starting fires, and awareness enables action. The Texas legislature supported a field demonstration project to document how utilities can use Texas A&M Engineering’s DFA technology to reduce wildfire-ignition risk.

Participants installed DFA on select circuits and worked with Texas A&M Engineering to become familiar with the technology. The utilities were charged with documenting examples of DFA-detected events of which they otherwise would have been unaware, paying special attention to events with ignition potential.

Branch on a Line

An early success at Pedernales involved a detached tree branch that hung on a remote single-phase tap on a long rural circuit. The 12.5-kV circuit has more than 150 miles (240 km) of circuit conductor and serves more than 1000 meters.

Most faults result from temporary conditions and can be cleared by momentary trip-and-close operations, with no action needed by the utility. However, certain incipient failure conditions also cause momentary interruptions, which temporarily clear the faults but do not heal the underlying conditions. DFA field installations have documented numerous instances in which line conditions cause recurrent faults. Sometimes the faults are separated by minutes or hours, sometimes by days or weeks. Each fault episode is cleared by a momentary trip-and-close operation, but additional faults continue until the underlying condition is corrected, or until it evolves into a permanent fault and perhaps causes damage to facilities.

In the subject case, the tree branch caused multiple faults over a period of several hours during a storm. Each fault was cleared by a trip/close of a hydraulic recloser, with no operation of the substation breaker. Pedernales received no customer calls and ordinarily would have taken no action. By recording and analyzing substation-measured current-transformer and potential-transformer waveforms for this circuit, DFA software characterized each fault. Because DFA maintains a fault history and compares each new fault to that history, when it detects multiple instances of what appear to be the same fault, it reports a recurrent fault cluster. In the subject case, DFA reported the branch-caused faults in this way, resulting in an investigation by Pedernales.

Like many distribution circuits, the subject circuit has many branches. Such a topology means predicting location based solely on fault current amplitude can result in multiple possible locations, resulting in inefficient patrols. Small fault currents generally result in more possible locations than large fault currents. Knowing which recloser is responding to the faults can focus patrols, but many reclosers are unmonitored, so the identity of the recloser must be inferred rather than determined directly by interrogating the recloser.

In the subject case, the recurrent faults drew a mere 300 A, so current-based prediction resulted in a significant number of potential locations. DFA reported each trip and close involved a single-phase recloser that temporarily interrupted approximately 15% of the affected phase’s load. After using this information to eliminate some of the circuit’s reclosers from consideration, Pedernales used its automated meter reading system to get blink counts from meters downstream of the suspected recloser and was able to confirm which recloser had been operating. Knowing this enabled a targeted patrol to locate the branch hanging on the line.

Without DFA, Pedernales likely would not have known about the problem. Once identified and located, correcting the problem was simple — remove the branch. The targeted patrol minimized crew time, and conductor damage was minimal. Had the branch remained undiscovered, it likely would have caused additional blinks and damaged the conductor. The branch on the line could have ignited, fallen free to the ground and started a fire. A more likely scenario would be progressive conductor damage, eventually dropping the conductor to the ground and potentially igniting a fire in that way.

Texas A&M Engineering has documented other recurrent faults, left uncorrected, that burned down lines or destroyed line equipment, causing lengthy outages; causes have included vegetation and damaged equipment. One that was very similar to the subject event involved a detached branch that eventually burned the line down. Despite more than a dozen trip-and-close operations from this branch, the utility in that case received no customer calls until the burned-down line caused a sustained outage.

Capacitor Management

With a fleet of more 530 capacitor banks to help maintain voltage and reactive power support, Pedernales has used DFA to detect and respond to multiple capacitor issues. Annual maintenance of banks detects failures such as blown fuses, but the annual nature of the cycle means a blown fuse can persist for months before being discovered. Other capacitor problems, such as internal arcing or partial loss of vacuum in a switch, need more timely response. In addition to multiple routine capacitor issues, DFA enabled Pedernales to correct a problem in which the close and open contacts for one phase of a bank had their leads swapped, causing the phase to come on when it was supposed to go off and vice versa. The utility has seen substantial value in using DFA for better oversight of its fleet of capacitor banks.

Unusual Events

DFA has made Pedernales aware of line events that are unusual but not recognized. One such event caused 23 single-phase current pulses, each 50 A to 100 A in magnitude, over a period of 13 seconds. The pulses were at regular time intervals, making the utility almost certain some sort of mechanical control was involved. The pulses were too large for a motor start or other individual load. Each pulse caused a voltage dip but lasted only about a cycle and, as measured from the substation, dipped the voltage by no more than 3.5%.

The cause of the pulses was not determined, and the event has not recurred. Still, knowing of such events has value. Customers sometimes report power problems about which the utility has no knowledge. Such problems can be difficult to diagnose. Investigations consume significant manpower and do not always lead to resolution. Having more information, from a sensitive continuous monitoring system such as DFA, can help the investigation. Similarly, when investigating customer problems, sometimes knowing the circuit is not experiencing events can have value and avoid wasting manpower looking for problems in places they do not exist.

Shared Experiences

A user group facilitated by Texas A&M Engineering has enabled Pedernales and other project participants to share their own experiences and gain from the experiences of others. Together, the group has documented a wide array of events:

• Detection and location of a broken insulator that resulted in a conductor heavily charring a wood crossarm

• Detection and location of arcing internal to a capacitor

• Detection, location and repair of multiple routine outages, without customer calls

• Detection and location of an intact tree intermittently pushing conductors together

• Detection and location of catastrophically failed lightning arresters

• Detection and location of an arc-tracked capacitor fuse barrel

• Detection and location of multiple instances of fault-induced conductor slap.

Most of these events represent the potential for ignition, given the right atmospheric conditions and available fuel loads. For each, the key DFA benefit was that it informed the utility that the problem existed.

Moving Forward

Distribution circuits have complex topologies, consisting of long lines and large numbers of components, spread over a large area. Situational awareness for such circuits is challenging. No technology detects all events, but Texas A&M Engineering’s DFA has shown the ability to inform utilities of many events of which they otherwise were unaware. Pedernales and other utilities are using Texas A&M Engineering’s DFA technology to improve situational awareness, thereby reducing fire ignition risk, making crews more efficient and improving the reliability and quality of electric service delivery. Based on successful trials, Pedernales and several other utility companies have begun expanding their deployments of DFA, integrating DFA into their work flows, and making DFA information available in their control centers. ♦

Robert A. Peterson is director of control center and emergency preparedness at Pedernales Electric Cooperative. He joined Pedernales in 1992 as system planning engineer and has held various positions at the cooperative prior to his current position. Prior to 1992, he spent 12 years at TU Electric (now Oncor) in various engineering roles. Peterson holds a BSEE degree from the University of Texas and a MBA degree from the University of Dallas. He is a registered professional engineer in Texas.

Carl L. Benner is a research associate professor in the department of electrical and computer engineering at Texas A&M University. He is an IEEE Fellow and holds BSEE and MSEE degrees from Texas A&M. His work centers on the application of advanced technologies to solve challenging power system problems, with an emphasis on waveform analytics. Benner is a registered professional engineer in the state of Texas. He is a member of the IEEE Power & Energy Society and Industry Applications Society as well as a member of CIGRE.

B. Don Russell is a distinguished professor in the department of electrical and computer engineering at Texas A&M University and is director of the power system automation laboratory. His research interests are in the application of advanced digital technologies to solve power system automation, control and protection problems. Russell is past president of the IEEE Power & Energy Society and an IEEE Fellow. He is a registered professional engineer in the state of Texas, vice president of the CIGRE U.S. National Committee and a member of the National Academy of Engineering.

Sidebar: The Distribution Fault Anticipator System

Texas A&M University’s College of Engineering has been developing distribution fault anticipator (DFA) technology since the late 1990s. Initially funded largely by the Electric Power Research Institute (EPRI), DFA research pursued the fundamental premise that line events, including incipient failures, cause measurable changes in line currents and voltages. Sensitively triggered, high-capacity, high-fidelity waveform recorders were installed in substations to monitor line currents and voltages of 70 distribution circuits during routine operations. These and subsequent installations have provided the largest extant database of high-fidelity waveforms from non-staged faults and other circuit events, with more than 1000 circuit-years of data. Study of that database enabled researchers to identify characteristics of many line events and implement algorithms to recognize and report them.

The state of Texas and other entities have provided substantial support to the development of DFA technology. DFA originally was an acronym for distribution fault anticipation, but the evolving development of the DFA technology resulted in its providing functionality that goes well beyond anticipation of faults. Power Solutions, LLC provides DFA technology commercially, under license from EPRI.

DFA technology is applied with a fleet of DFA monitoring devices and a central DFA master station. Each DFA device is installed in a 19-inch rack in a substation, monitors a single distribution circuit via conventional current transformers and potential transformers, and connects to a DFA master station at a central location through secure internet.

The DFA master station is a server computer with custom DFA software. It retrieves reports from the fleet of DFA devices and makes the reports available to users through a secure, password-protected website. The secret-sauce software that analyzes electrical waveforms to characterize line events resides in each circuit’s DFA device. The system architecture is intended to make the system scalable because the centralized master station does not have to perform complex pattern-recognition computations. As algorithms are improved over time, the master station pushes new software to the fleet of devices.

Sidebar: Maximizing Use of DFA Technology

Pedernales Electric Cooperative synergistically uses other tools to get the most benefit from distribution fault anticipation (DFA) and plans to use these more as it deploys DFA more broadly. The circuit model software can help to predict fault locations based on measured fault current amplitude. Its AMR system enables daily blink counts to determine which of a circuit’s multiple reclosers is operating in response to recurrent faults. The AMR system also enables pings of selected meters to confirm suspected outages. AMR system constraints generally make it infeasible to ping on a circuit-wide basis. However, pinging a small number of meters — preselected based on DFA and circuit model information — can provide timely, useful information for problem resolution.

As an example of synergistic use, consider a scenario in which DFA reports a recurrent fault-causing intermittent momentary trip-and-close operations of an unmonitored recloser on a long circuit with multiple reclosers. DFA parameters can be used to infer which recloser likely is operating. AMR blink counts can be used to confirm the recloser. Circuit model software, using DFA-provided fault amplitude, can be used to predict location. Patrols then can be targeted beyond the recloser that is operating and further targeted by the prediction based on fault current amplitude. In such a case, DFA provides the most important element — awareness of the problem — then the multiple tools are used together to locate and enable repairs.

About the Author

Robert A. Peterson

Director of Control Center and Emergency Preparedness

Robert A. Peterson is director of control center and emergency preparedness at Pedernales Electric Cooperative. He joined Pedernales in 1992 as system planning engineer and has held various positions at the cooperative prior to his current position. Prior to 1992, he spent 12 years at TU Electric (now Oncor) in various engineering roles. Peterson holds a BSEE degree from the University of Texas and a MBA degree from the University of Dallas. He is a registered professional engineer in Texas.

Carl L. Benner

Research Associate Professor

Carl L. Benner is a research associate professor in the department of electrical and computer engineering at Texas A&M University. He is an IEEE Fellow and holds BSEE and MSEE degrees from Texas A&M. His work centers on the application of advanced technologies to solve challenging power system problems, with an emphasis on waveform analytics. Benner is a registered professional engineer in the state of Texas. He is a member of the IEEE Power & Energy Society and Industry Applications Society as well as a member of CIGRE.

B. Don Russell

B. Don Russell is a distinguished professor in the department of electrical and computer engineering at Texas A&M University. He is the director of the Power System Automation Laboratory. His research interests are in the application of advanced digital technologies to solve power system automation, control and protection problems. Russell is past president of the IEEE Power & Energy Society and IEEE Fellow. He is a registered professional engineer in the state of Texas, vice president of the CIGRE U.S. National Committee and a member of the National Academy of Engineering.