10 Tips for Installing Smart Meters in the Field

Two years ago, Central Maine Power Co. (CMP) swapped out 600,000 traditional meters with smart meters funded in part through a $96 million investment grant from the Department of Energy. To secure the grant, the utility had to describe the full approach it would take in the smart meter program, present a cost-benefit analysis, include letters of support and propose a governing structure for the project, such as how to track metrics.

Through the American Reinvestment and Recovery Act, the utility was awarded the grant in October 2009, meter installation began in September 2010 and the utility deployed more than 99% of the smart meters by June 2012. Today, the utility is continuing to discover new ways to improve customer service, operational efficiency and the safety of its field workforce.

Following are 10 strategies CMP found to be successful while deploying smart meters to the field.

1. Turn to Other Utilities

Back in 2006, CMP saw smart grid technology as a potential avenue for operational efficiency and strategic opportunity. The utility started garnering support from regulators, exploring products from vendors and meeting with other utilities.

For example, CMP has a long-standing relationship with Emra Maine, its neighbor to the north. In addition, the utility conferred with many other companies in Texas, California and Pennsylvania before hiring VSI Meter Services Inc. (now Grid One Solutions Inc.) to install the smart meters and network from Landis+Gyr, Trilliant and General Electric over its 11,000-sq-mile territory.

2. Plan Ahead

After talking with other utilities, CMP began identifying some of their lessons learned and putting them into practice. For example, rather than starting an outreach program 30 days before deployment, CMP followed in Pacific Gas & Electric’s (PG&E’s) footsteps and adopted an outreach schedule PG&E called the T-75 plan. Seventy-five days before the utility started deploying meters in an area, it reached out to town officials to identify any concerns, present at town meetings and engage the community ahead of time to support the deployment. That way, when the fleet of field technicians arrived on site ready to install the smart meters, the town officials and community were already aware of the program and supportive of the initiative.

Through the T-75 process, CMP organized several hundred meetings in 300 small towns to educate the town officials and community leaders about the process and benefits of the smart grid program as well as to answer their questions. With the citizens in the small towns often very involved in the local government, CMP learned the meetings were an effective way to identify concerns and communicate its plan for smart grid deployment.

3. Identify Issues with Meter Enclosures Early

Maine has the oldest housing stock on average in the country, so many of the older homes have vintage meter boxes. In addition, many of the meter boxes do not meet modern codes. Before CMP could even start installing the smart meters, the utility first had to replace meter boxes on some properties.

A full year before the smart meter deployment began, CMP surveyed all of its meters to collect data on the age and status of its meter enclosures. The utility then systematically began replacing some of the oldest meter enclosures proactively to ensure efficient and safe meter deployment.

4. Have Field Electricians on Standby

As CMP began to swap out 600,000 meters, it quickly discovered some of the meter enclosures were not only old but substandard or unsafe. In many cases, this would have presented a delay or a financial hardship on families, who typically would need to pay an electrician to install a new meter enclosure, which could foster ill will toward the utility.

Instead, the utility followed Bangor Hydro’s example by having electricians on call on an emergency basis to replace any meter enclosure that was dangerous or had any issues. While it did not cost CMP a significant amount of money relative to the scale of the project, it provided a much safer situation for the field technicians and homeowners, it supported customer satisfaction and it kept the project moving without costly delays.

5. Communicate with Customers

Throughout the project, constant communication with the homeowners and landowners was key to CMP’s success. CMP reached out to its customers in advance of installation. In addition, each time a meter installer arrived on site, he or she would knock on the door to find out if the customer was home.

Next, the installer would alert the homeowners about the short blip in electricity that would occur during the change out. Although the power was interrupted only briefly, it could cause an inconvenience. For example, if a homeowner was working from home on a computer, the advance warning of the power interruption would give them time to save their work.

If the customer was not home while the technician was on site, then the technician would leave a door hanger with contact information and a description of the work performed. CMP’s meter installer also had a call center, which would provide customer assistance, answer questions and help with scheduling issues.

6. Collect Data

During the deployment, CMP learned the importance of gathering data while still on a customer’s property. For example, the meter technicians took photos of changed out meters, and these pictures helped to resolve any questions from customers regarding final readings from the old meter or the condition of the meter enclosure.

In addition, technicians also collected data on GPS coordinates, which later proved invaluable during outage management. Now when a customer reports an outage, dispatchers can quickly determine whether it is an issue behind the meter or simply a meter malfunction. By pinging the meter, the dispatcher can find out if the power is on or not, saving time for the field crew by avoiding an unnecessary service call.

7. Rely on Outside Installation Crews

During the project, the work was generally grouped into two sections: IT technology and infrastructure deployment. CMP relied on both in-house and external crews to deploy hundreds of thousands of meters across its service territory in about 18 months.

For the straightforward installations, which accounted for about 90% of the installations, the contract meter installer handled the projects and the in-house meter technicians handled the transformer-rated installations, requiring complex metering. CMP also turned to an outside company to help create its wireless network, which was daunting in light of Maine’s hilly terrain, rural housing and dense tree cover in many areas.

During the deployment, CMP was very data- and metric-driven. The utility could track meter installations on a daily, weekly and monthly basis. In rolling out the wireless network across the area, CMP used the same data-driven approach to track meter and network status, including bringing the meters on-line, securing them and then achieving reads.

8. Educate Field Crews about New Technology

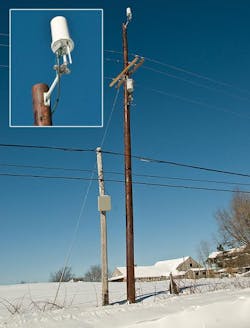

The wireless network, which is installed for the smart meter system, uses the same network to communicate with three-phase reclosers on the distribution system. These reclosers are fully automated, and they allow CMP to clear a fault remotely, which increases the efficiency of its restoration process, and reduces the frequency and duration of customer outages. CMP is optimizing its smart meter network and is getting a second layer of functionality out of its wireless network.

To teach its line crews how the reclosers as well as the other intelligent devices would operate, CMP created a cross-functional team to develop processes and training, and encouraged active involvement from the field supervisors and line crews. The utility then put together a training program of how the technology worked and how the network devices would be installed and maintained, which was integral to the utility’s success going forward.

During the deployment, CMP also brought its field professionals to a training facility, where the utility had set up a demonstration pole top so the linemen could view the equipment and learn how to install it.

9. Train the Field Workforce

When CMP deployed its smart meters across its service territory, it went from a purely wires-and-poles utility to the largest wireless facility in the state of Maine, which brought about both challenges and opportunities. Over time, the utility came to understand what it would take to operate a large, complex wireless system. The company is now more technology focused and requires a different set of skills in the field.

Today’s meter technicians must now understand how to troubleshoot the system with a radio and a laptop. During the deployment, they had to learn additional skills with increased levels of technology. In addition, linemen also had to learn about the new advanced metering infrastructure (AMI) devices on the pole, because, as an example, during a storm restoration, they may encounter not one but three or four different types of smart devices. In these events, they may work alongside a radio-frequency technician to install any technology damaged by the severe weather.

The utility’s system now has more than 800 network collector devices installed on its poles, and after a storm or car pole accident, they are one more element of the restoration. After linemen remove the AMI components from the pole, all the communications and troubleshooting at the software level is then managed at the technician level.

10. Give Meter Readers New Opportunities

In the past, CMP’s meter readers drove more than 2 million miles each year in rural and urban settings. While on site, they were often at risk for getting bitten by dogs, bumping their heads in dark basements, slipping on sidewalks, getting tick bites or contracting a poison ivy rash. In addition, the technicians were frequently in the line of fire when it came to irate residents.

By installing the smart meter technology, CMP has reduced the risk of exposure for its in-field technicians. Rather than laying off its meter reader employees, the utility instead announced its plans for the smart meter deployment early in the process and, when it came time for the deployment, offered a voluntary severance package to the meter readers or gave them the chance to look for other opportunities within the utility.

For example, former meter readers are now working on credit collection, performing meter testing in the field and reading meters for those who cannot collect the data through the network. These employees are quickly learning the new technology and functionalities, and taking on new responsibilities within CMP. The meter technicians also are supporting the communications, performing site surveys and determining the placement of network devices to solve problems.

By installing the smart meters, CMP is increasing the amount of information it can deliver to the field, enabling faster outage-restoration times, improving automation and efficiency for both its field and office personnel, and detecting diversion and tampering violations.

Laney Brown ([email protected]) is the director of smart grid planning and programs and has been with the Central Maine Power Co. for 11 years.

Paul Sisson ([email protected]) is the manager of meter services for Central Maine Power Co. and has been with the utility for 32 years.

Mentioned in this article:

Central Maine Power Co. | www.cmpco.com

Emera Maine | www.emeramaine.com

General Electric | www.ge.com

Grid One Solutions Inc. | www.gridonesolutions.com

Landis+Gyr | www.landisgyr.com

Pacific Gas and Electric Co. | www.pge.com

Trilliant | www.trilliantinc.com