A rural county in the heartland doesn’t usually come to mind when one thinks of aggressive growth in electricity services and demand. And with a population creeping at less than the national average, Noble Rural Electric Membership Cooperative (REMC) doesn’t look like an ordinary candidate for aggressive load control. Yet, this is the challenge Noble REMC is facing and the strategy it is taking with great success.

Demand Rises

In an agricultural economy, crop yield can make the difference between a good living and losing the farm. With unirrigated acreage yielding 80 to 90 bushels an acre, and irrigated acreage at more than 200 bushels, new irrigation pivots are springing up like mushrooms across northeastern Indiana.

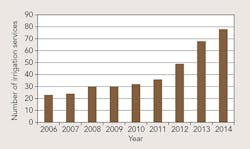

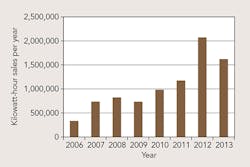

A significant drought hung over the region in 2012. Suddenly farmers who were only considering irrigation became true believers, and Noble REMC saw a 39% increase in one year in the number of farmers with irrigation systems. In fact, 2013 was the most intense year since 2006 when Noble began tracking the growth of irrigation systems across its service territory. In the eight years between 2006 and 2014, the average increase in the number of members with irrigation systems was 17% annually, and the average annual kilowatt-hour growth rate from these systems was a whopping 32.7%.

This trend did not catch the team at Noble REMC by surprise. Although there are only 32 employees at the utility, the engineering team had already begun investigating potential solutions. First, it began looking at replacement technology for its power line carrier automated meter reading (AMR) system. At about the same time, the utility’s wholesale power supplier, Wabash Valley Power Association (WVPA), introduced a new load management program with opportunities for substantial savings.

In order to participate in the WVPA load management program, Noble expanded its investigation of advanced metering infrastructure (AMI) system vendors to include load management, adding that capability to the reliable communications network and standard meter reading functionality the utility was already seeking.

Load management was not a new concept to the utility. Noble REMC had a load management program for almost 30 years that included 3000 electric water heaters. That program abruptly closed down in January 2013 when FCC narrowbanding requirements obsoleted that communications network. Now, with the surge in growth of new irrigation accounts, Noble REMC worked with AMI vendor Elster Solutions, channeling its search for the right AMI into this new direction.

Technology Challenge

Elster proposed two standard solutions to load management requirements. A ZigBee load management device designed for residential water heaters and a large three-phase load management switch for the irrigation systems. The load management devices using the ZigBee communications system would work well for the water heater switches, but because of the great distances and often dense vegetation, the ZigBee option was not a good fit for the irrigation load management. The three-phase load management switch was designed for larger motor-driven loads and would require considerable work to retrofit the existing 78 irrigation systems. Neither was the right fit from Noble REMC’s perspective.

After reviewing Elster’s entire product offering, the engineers at Noble REMC concluded that Elster’s surface-mounted smart meter (called the gREX) outfitted with a load-break switch could be used both for load management of the irrigation systems and the water heaters. The gREX uses Elster’s native 900-MHz communications network that would be deployed throughout Noble REMC’s service territory to provide the reliable propagation needed to support load control as well as metering. Using a single solution for both forms of load control would simplify program management and eliminate the need to bring in meters with a secondary ZigBee communications layer.

In doing its research, Noble REMC discovered there are many types of irrigation systems at various levels of sophistication. The utility eventually developed four basic load control equipment configurations to handle the irrigation pivots deployed in its service territory. Some pivots are computer controlled and can be managed remotely with a smart phone. For others, the farmer has to drive up to the pivot center and manually start the operation. The utility discovered that it was more economical and less complicated to use the equipment that the farmer was using to start and stop the pump, rather than to install additional equipment. Although the pumps are large (up to 125 hp), the circuit typically uses a simple magnetic switch for on/off operation, so very little power is needed to break or close the circuit.

The important factor for Noble REMC is the reliable communication with and operation of the devices in the field. Using a Batch Request tool in Elster’s EnergyAxis Management System, Noble REMC is able to automate the control messages and activate the disconnect action within minutes of receiving the control signal from WVPA. Similarly, the end of control message gets a rapid response, quickly restoring power to the irrigation pivots. The Elster system provides verification of the switch state back to Noble REMC, and Noble uses its supervisory control and data acquisition (SCADA) system to provide a second layer of validation of the operation of the system.

Load Control Economics Benefit All

Although Noble REMC developed and installed the load management system, its wholesale power supplier actually owns and operates it. WVPA worked with Midcontinent Independent System Operator (MISO), a regional transmission provider that serves a portion of Noble REMC territory; if WVPA’s irrigation demand response program reduces the demand, it will lower the capacity obligation of WVPA. WVPA has the ability to sell that power back onto the grid, which can be a significant boost to WVPA’s revenue.

WVPA discounts its wholesale rates to Noble REMC in return for the utility’s participation in the load control program. Although Noble’s former load management program consisted of 3000 water heaters, the approximate 80 irrigation systems now under control generated an equivalent amount of load shed capability in a much more expedient timeframe, enabling Noble REMC to quickly capture the offered savings from WVPA. Additional savings will be generated when the water heaters are added to the program.

Finally, farmer members get a 21% discount for participation in the program. The discount applies whether the control is applied or not. Participating farmers receive the discount — averaging around $400 per month this summer — and they only had their systems controlled once during the relatively cool summer of 2014.

Recruiting Participants

Noble REMC was eager to get 100% participation and fully engage members with irrigation systems. The utility used a winter breakfast event to introduce farmers to the opportunity. Despite heavy snow, the room was warm, the coffee strong and the atmosphere congenial. The utility quickly succeeded in signing up 95% of the eligible systems, bringing 3.1 MW under control.

To reinforce participation, Noble REMC did not charge the farmers for the control equipment and the labor involved in installation. The utility also changed its printed bill to include a line that clearly shows the credited savings. Again, the savings accrue regardless of whether any control events were initiated.

The program includes several limits and qualifications that reduce the impact to crops even during the driest and hottest of summers. An additional deciding factor for customers was a once-a-year “opt out” of their choice.

Despite good payback and reasonable flexibility, at least 5% of farmers with irrigation systems chose not to participate. Noble REMC dug around to find out what was preventing participation. In most cases, it turned out to be the type of crop: potatoes and seed corn.

When potato farmers start watering the fields the beginning of June, they don’t quit. The irrigation runs at an amazing 99% to 100% load factor pumping 1200 gal (4542 l) a minute for the entire growing season. In Noble County, farmers rotate in and out of potato crops over the years, so they may move into and out of Noble REMC’s load control program annually.

Seed crop farmers cannot participate in load control because of strict contractual obligations. When a seed corn producer calls and says “apply 1.5 inches of water right now,” the farmer is legally obligated.

Noble REMC has a webpage with additional details used to recruit new irrigation participation. Plus, managers at the utility are certain that the farmers talk among themselves, sharing information about the program and watching their bill every month for the program credits. Sometimes word-of-mouth and an engaged customer base is the strongest form of marketing.

Where To From Here?

Noble REMC began its load control initiative in January 2014 and completed installation of the equipment on 78 irrigation pivots by June 2014, effectively putting 3.1 MW under control. By late July, however, a few of the system communications were becoming less reliable. Field testing indicated that dense and growing vegetation was attenuating the signal strength. Using a handheld radio-frequency signal device, utility engineers determined that communication reliability would greatly improve by raising the surface-mounted gREX meter higher on the pivot.

Noble REMC is now busy adjusting the location of the equipment, which enables the communications signal to float over the tall corn and more easily achieve the distances needed in this largely rural county. With only 8.9 meters per mile of line and irrigation pivots that average 1320 ft (402 m) in length, the AMI network surrounding these pivots is quite sparse. With the increased height, network performance improves without any need for repeating devices.

The utility is also eager to determine if the rate structure for irrigation load control is equitable. The summer of 2014 was not ideal for data collection, with operations interrupted only one time during the four-month program. Although no one hopes for another drought, the rate team at Noble REMC would like to capture data that more closely approximates average summer temperatures and rainfall in northeastern Indiana.

As the irrigation project continues to mature, Noble REMC will also begin to re-engage residential customers in the water heater load control program. There are savings to be generated and passed along to their consumers. Noble REMC is hard at work to provide reliable service, fair rates and environmentally sound programs for its members — and a bounty of corn for consumers’ tables or ethanol for their cars.

Douglas D. Dickmeyer ([email protected]) is a system engineer for Noble REMC. In addition to his supervisory role in the metering department and his project manager role, he developed the two-year construction work plan and the 10-year construction work plan for Noble REMC. He also performs distribution duties for the cooperative. He previously worked as an electrical engineering consultant in the building industry, designing electrical systems for hospitals, schools, libraries, factories and office buildings. Dickmeyer is a registered professional engineer.

Mentioned in this article:

Elster | www.elster.com

Noble REMC | www.nobleremc.com

Sidebar: Pivot Irrigation Primer

People who fly over the United States marvel at the ubiquitous green crop circles, especially in the plains states. However, odds are that few people know much about the circular irrigation technology.

Center pivot irrigation consists of pipe supported by trusses, mounted on wheeled towers with sprinklers along its length. Water enters the system at the center of the circle. The outside set of wheels sets the master pace for the rotation (typically the circle is completed every three to four days).

Center pivots used by farmers in Noble County, Indiana, are as long as 2000 ft (610 m); the most common size of pivot irrigation used in the U.S. is 1320 ft (402 m). To achieve uniform application, center pivots require an even flow rate across the radius of the machine. Since the outer spans travel farther in a given time period than the inner spans, nozzle sizes are smallest at the center and increase with distance from the pivot point. Center pivot irrigators apply approximately 1200 gal (4542 l) a minute.

Originally, center pivots were water-powered. Today, most systems are driven by an electric motor mounted at each tower. An additional electrical demand is created by the pumps used to draw groundwater into the irrigation pivot. In most cases, electricity is transmitted to the motor and pump via underground service.